Mechanics of Machining Processes

Mechanics of Machining Processes

Mechanics of Machining Processes

Mechanics of Machining Processes

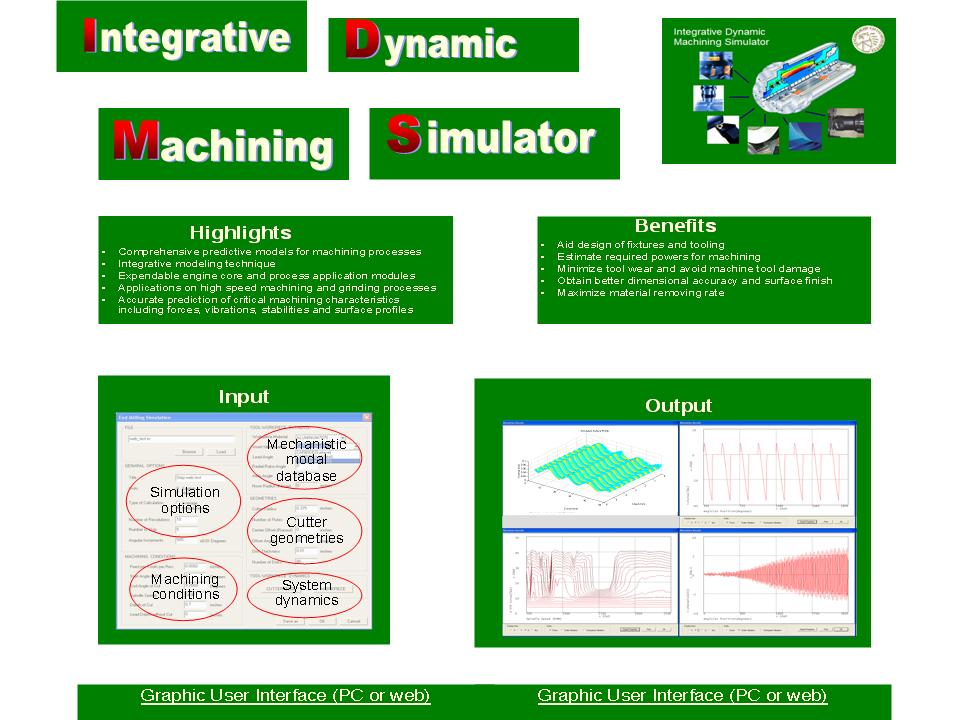

In the Advanced Machining Laboratory, research projects are being undertaken to study various fundamental mechanics of machining processes and to develop predictive models. The topics include mechanistic modeling of cutting processes, prediction of tool wear effect on cutting forces, FEM modeling of machining processes, investigation of relationships between machining conditions and surface integrity, constitutive modeling of materials by machining processes, investigation of chip flow angles in three dimensional cutting, and analysis of cutting temperatures. Please see the published papers for details. Some highlights of these projects are briefly described below.

![]() Mechanistic

Modeling of Cutting Processes

Mechanistic

Modeling of Cutting Processes

![]() Finite Element Modeling of Machining Processes

Finite Element Modeling of Machining Processes

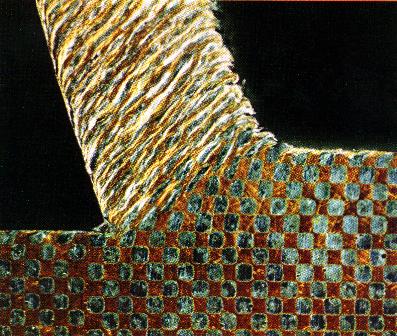

![]() Multiscale Modeling of Composite Machining

Multiscale Modeling of Composite Machining

![]() Effect of

Tool Wear on Cutting Force

Effect of

Tool Wear on Cutting Force

![]() Development

of Material Constitutive Models

Development

of Material Constitutive Models

Strains and strain rates encountered during machining processes often far exceed what one can get from standard mechanical tests. Therefore, in order to predict material deformation during machining, conventional constitutive models cannot be extrapolated and used. To develop a suitable constitutive model, controlled orthogonal machining experiments are used to develop a constitutive model.

Stresses are obtained in terms of strain, strain rate and temperature from orthogonal machining tests based a new shear zone model.

|

|

Calculated shear strain rate using new shear zone model |

Comparison of calculated flow stress with Oxley's results for 1020 steel |

![]() Thermo-mechanical

Modeling of Machining Processes

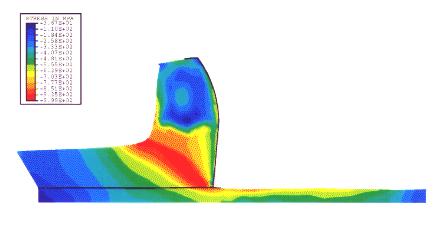

Thermo-mechanical

Modeling of Machining Processes

Numerical simulation of machining processes has been performed to obtain coupled solutions of plastic deformation and thermal field. Temperature dependent material properties are used and adaptive meshing is adopted to avoid numerical errors associated with large deformation.

![]() Tool-Chip

Temperature Analysis

Tool-Chip

Temperature Analysis

![]()

Comparison of measured tool-work interface temperatures with model prediction

![]() Workpiece

Temperature Analysis

Workpiece

Temperature Analysis

Temperature measured by an IR system during machining

[ Welcome ] [ Research

] [ Education ] [ Laboratories ] [ Collaboration

]

© 2000 Purdue ME Manufacturing Laboratories

Last modified by Web Master, 21 February 2005.