|

|

|

|

|

Andrea's Research |

|

External Gear Pumps/Motors

HYGESimThe main result of the research activities in external gear machines is given by the simulation tool HYGESim. HYGESim (HYdraulic GEar machines Simulator) is a numerical model for the simulation of external spur gear pumps and motors. Conceived at University of Parma (Italy) with the support of the company CASAPPA, HYGESim is currently developed at MAHA Fluid Power Research Center. The simulation tool consists of different modules: a lumped parameter fluid dynamic model, a mechanical model for evaluation of the gears motion (considering also the micro motion of the gear axes of rotation) and a geometrical model. The first two models are implemented within the LMS Imagine.Lab AMESim® simulation environment, with proper submodels written in C language, while the geometrical model is implemented developing proper macros capable to read directly the CAD3D drawings of the unit (pump/motor).

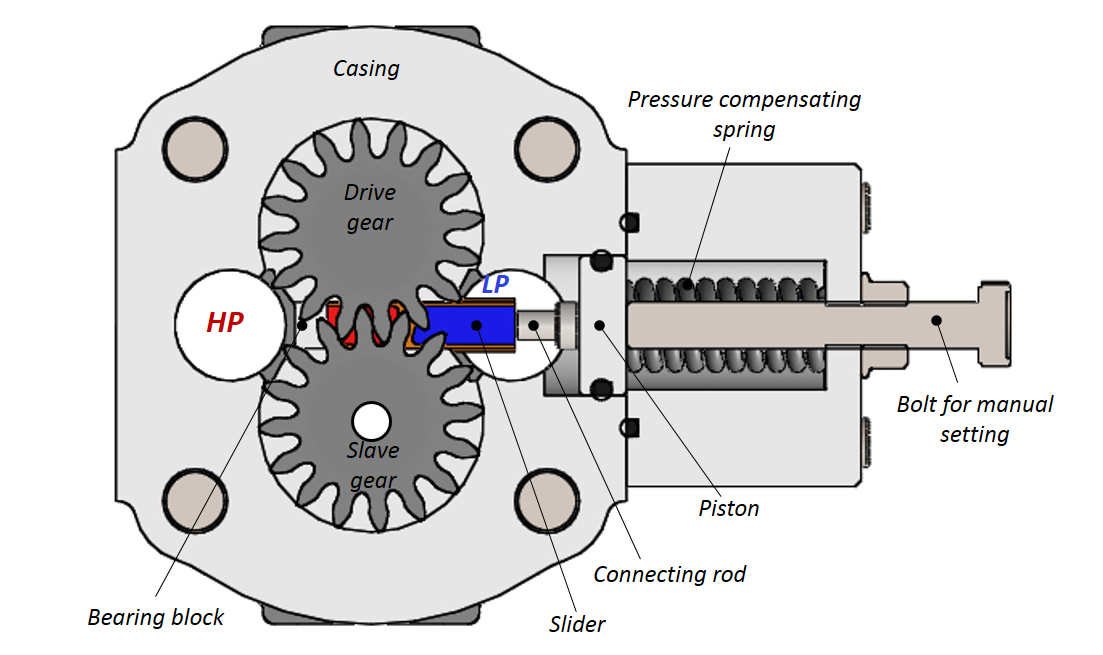

The simulation tool is characterized by an accurate description of the geometry of the different components (i.e. teeth’s profile, design of sliding elements) and it is able to calculate the movements of the gears’ axes of rotation resulting from the forces exerted on both gears. Potentials of the model are represented by the prediction of the main features of flow through the machine (such as the inter-teeth meshing pressure, the evaluation of possible cavitation onsets, pulsation of flow at the external ports, etc.) and the detection of the wear of the casing due to the possible contact between the gears and the casing. The tool is currently used for the analysis of the main phenomena related to the operation of the machine, for the optimization of its design and for the research of innovative solutions. Noise Modeling in Gear PumpsNoise generation in the pumps and motors is commonly classified into three categories in many studies of noise in hydraulic applications: fluid-borne noise (FBN), structure-borne noise (SBN), and air-borne noise (ABN). To have better understanding of noise generation in external gear machines, a complete FBN-SBN-ABN model has been developed using proper methodologies for each domain. HYGESim provides all the FBN sources inside the units. For the prediction of the SBN and the ABN, a combined FEM/BEM approach is used in conjunction with mapping the predicted FBN sources as loads to the pump structure. The model is suitable for quieter pump design through virtual prototyping methods based on numerical optimization without negatively affecting the energy efficiency. The model is also suitable to separate and quantify the different FBN and SBN sources to the ABN noise. In this way, it is expected that general design guidelines will be provided to the technical fluid power community involved in pump design efforts. Variable-Displacement Gear PumpGiven the importance of efficiency in any mechanical system, in recent years, displacement control of pumps has gained a lot of attention in the field of fluid power. Gear pumps have a lot of advantages in that they are of simple design, fewer moving parts, easy to maintain and very compact. However, gear pumps available in the market today are fixed displacement. By allowing variable displacement, the advantages of gear pumps can be utilized in wider applications. The project aims to demonstrate the commercial viability of a Variable Displacement Gear pump using a novel principle. The idea of changing the displacement is based on varying the timing of the connections of the Tooth Space Volumes (TSV's) with the inlet and outlet grooves. We achieve this by introducing a movable element, called "slider." In traditional pumps the grooves are machined onto the lateral bushings. The slider element allows us to change the position of the inlet and outlet grooves with respect to the TSV's.  For this project, a parametric optimization to increase the displacement reduction of the gear profiles was performed in modeFRONTIER. The performance of the optimized pump was simulated in HYGESim. The project aims to build prototypes for different pressure applications. One for high pressure (~200 bar) and another for lower pressure (~15 bar). The high pressure prototype has been built with a pressure compensated design. It was tested and the prototype was able to implement the pressure compensation principle. Currently the design of the low pressure prototype is being finalized. This prototype will be capable of electronic displacement control. This is achieved by controlling the slider position using an electro-mechanical actuator like a solenoid or stepper motor. Downloads:

|

|

|

Gear Ring (Gerotor) Units

With the support of MAGNA Powertrain the developed models have been

successfully validated with experimental results for different pump

designs for both, steady state and transient pump operation. |

Multimedia:Downloads: Videos:

|

|

|

Multi-Purpose Test Rig for Automatic Components Testing

Main features of MPTR are:

|

|

|

|

|