Research at CORIA

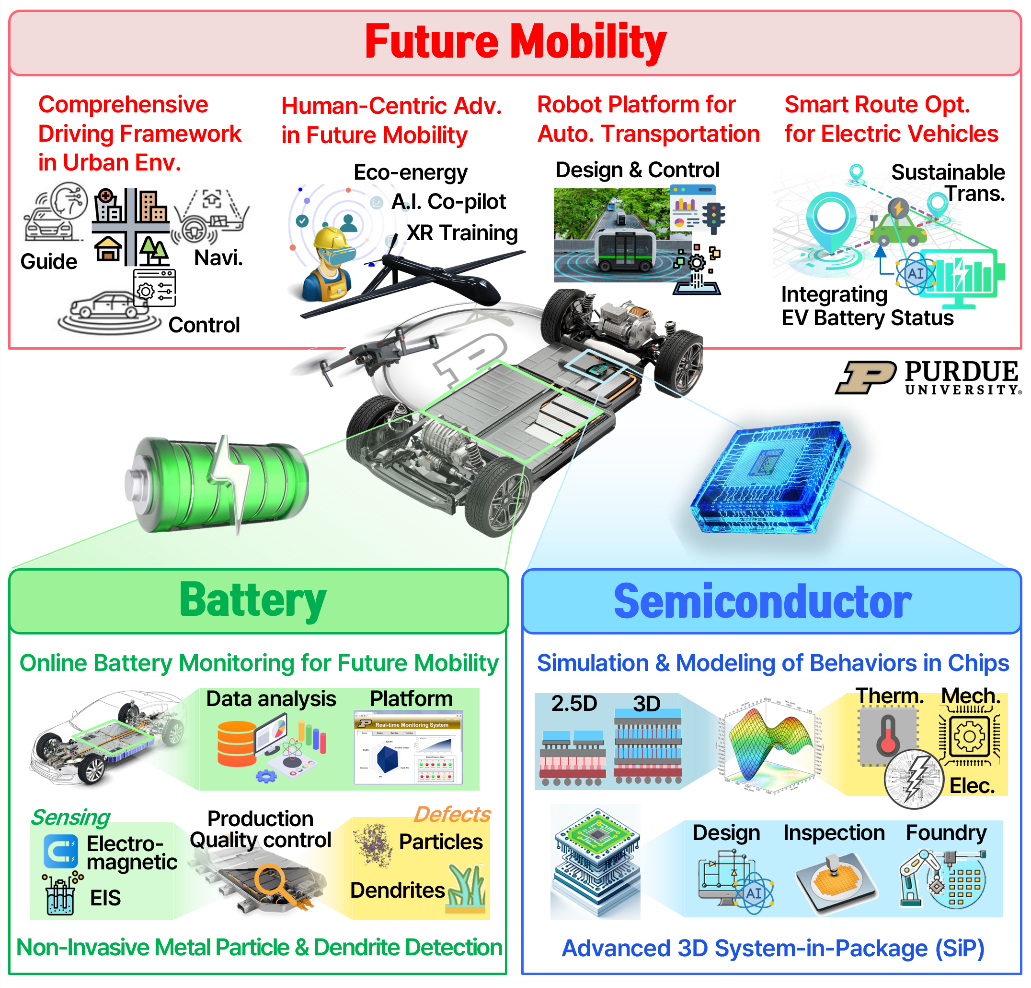

At CORIA, our research is driven by the goal of advancing innovation and addressing global challenges in Future Mobility, Batteries, and Semiconductors. Each research area is strategically designed to foster groundbreaking discoveries and support the development of transformative technologies.

At CORIA, our research is driven by the goal of advancing innovation and addressing global challenges in Future Mobility, Batteries, and Semiconductors. Each research area is strategically designed to foster groundbreaking discoveries and support the development of transformative technologies.

Future Mobility

CORIA is at the forefront of shaping the future of mobility by developing advanced technologies for autonomous transportation, urban air mobility, and human-centric solutions. Our research focuses on creating comprehensive guidance, navigation, and control frameworks for autonomous systems in complex urban environments, enhancing safety, efficiency, and sustainability. By integrating human-autonomy teaming models and collaborative technologies, we aim to redefine transportation systems, ensuring seamless interactions between manned and unmanned vehicles. From autonomous vehicles to innovative air mobility solutions, CORIA drives forward-thinking advancements to transform the way we move.

Batteries

Our research on next-generation batteries centers on improving safety, reliability, and efficiency to meet the growing demands of electric vehicles (EVs) and sustainable energy systems. By combining electromagnetic and electrical impedance sensing technologies, CORIA is enhancing non-invasive battery diagnostics and quality control for production lines. We are also developing advanced online battery monitoring systems that utilize Artificial Intelligence (AI) to predict battery health and optimize performance in real-time. These innovations are critical for ensuring the reliability of battery-powered mobility and expanding the adoption of sustainable energy solutions globally.

Semiconductors

Semiconductors are the backbone of modern technology, and CORIA is leading the charge in advancing semiconductor design, packaging, and integration. Our research tackles challenges in 3D system-in-package (SiP) technology, focusing on thermal, mechanical, and electrical co-simulation tools to improve design automation and reliability. Collaborating with global industry leaders, CORIA develops innovative solutions for next-generation electronic systems, addressing critical needs in high-performance computing, artificial intelligence, and advanced manufacturing. By pushing the boundaries of semiconductor innovation, we enable smarter and more efficient technologies for a rapidly evolving world.

Ongoing Projects

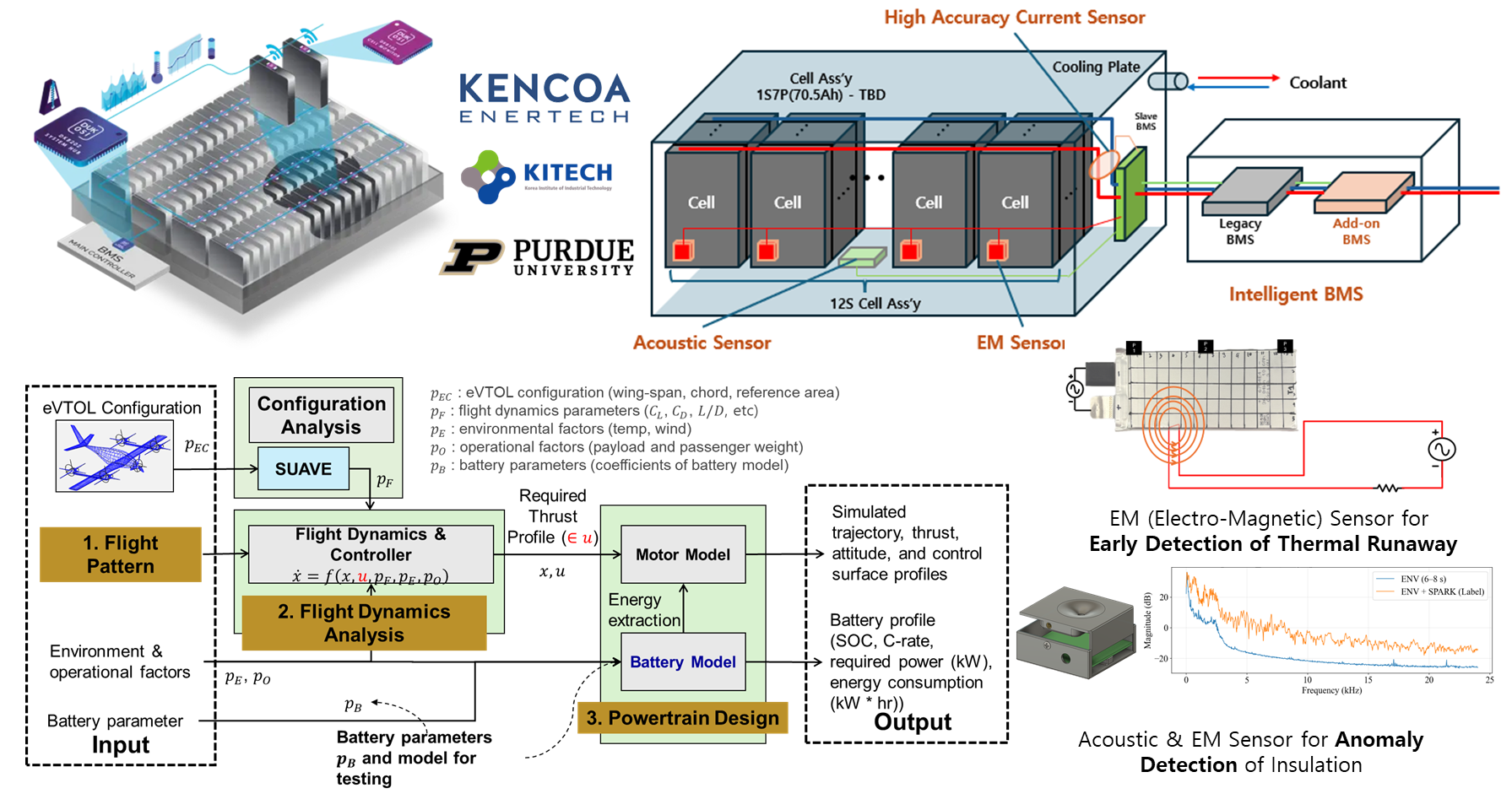

Advanced Battery Management System for Real-time Flight Range Optimization and Stability Enhancement of AAM Aircraft with Non-Intrusive Sensor Fusion (Purdue PI: Martin Byung-Guk Jun, Byunghoo Jung, and Inseok Hwang)

Advanced Air mobility (AAM) aircraft depend on high-performance batteries, yet their operating environment is far more demanding than that of electric vehicles. Vertical takeoff and landing require extremely high discharge rates, rapid power fluctuations, and frequent fast-charging cycles, which significantly accelerate cycling-induced aging and increase the difficulty of assessing remaining usable energy. These harsh conditions heighten the risk of thermal runaway and make accurate predictions of flight capability and safe-landing margins essential. Because most existing diagnostic technologies were originally developed for EV applications, they fall short of the precision, responsiveness, and safety requirements of AAM platforms.

Advanced Air mobility (AAM) aircraft depend on high-performance batteries, yet their operating environment is far more demanding than that of electric vehicles. Vertical takeoff and landing require extremely high discharge rates, rapid power fluctuations, and frequent fast-charging cycles, which significantly accelerate cycling-induced aging and increase the difficulty of assessing remaining usable energy. These harsh conditions heighten the risk of thermal runaway and make accurate predictions of flight capability and safe-landing margins essential. Because most existing diagnostic technologies were originally developed for EV applications, they fall short of the precision, responsiveness, and safety requirements of AAM platforms.

This project aims to develop an Advanced Battery Management System (ABMS) purpose-built for AAM by integrating non-intrusive sensing, multi-modal sensor fusion, and real-time aging diagnostics. Mission-profile modeling enables extraction of representative power-usage patterns across takeoff, cruise, landing, and disturbed flight scenarios, providing the foundation for reliable state-of-charge and state-of-health estimation. High-resolution current sensing, electromagnetic sensors, and real-time impedance extraction allow early detection of anomalies such as insulation degradation, DC spark events, and the initial indicators of thermal runaway that cannot be captured with conventional embedded sensors. Sensor-fusion algorithms that combine current, EM, and acoustic data enhance diagnostic resolution and robustness under varying loads.

The project establishes a coordinated development framework across industry, research institutes, and international partners to validate sensor modules, implement diagnostic algorithms, and integrate the technology into prototype battery systems. The expected outcomes include improved prediction of remaining flight time, early identification of hazardous fault conditions, and enhanced safety functions that reduce catastrophic battery risks. Through these advancements, the ABMS will support optimized flight-range planning, greater operational stability, and a strong technological foundation for future AAM certification and commercialization.

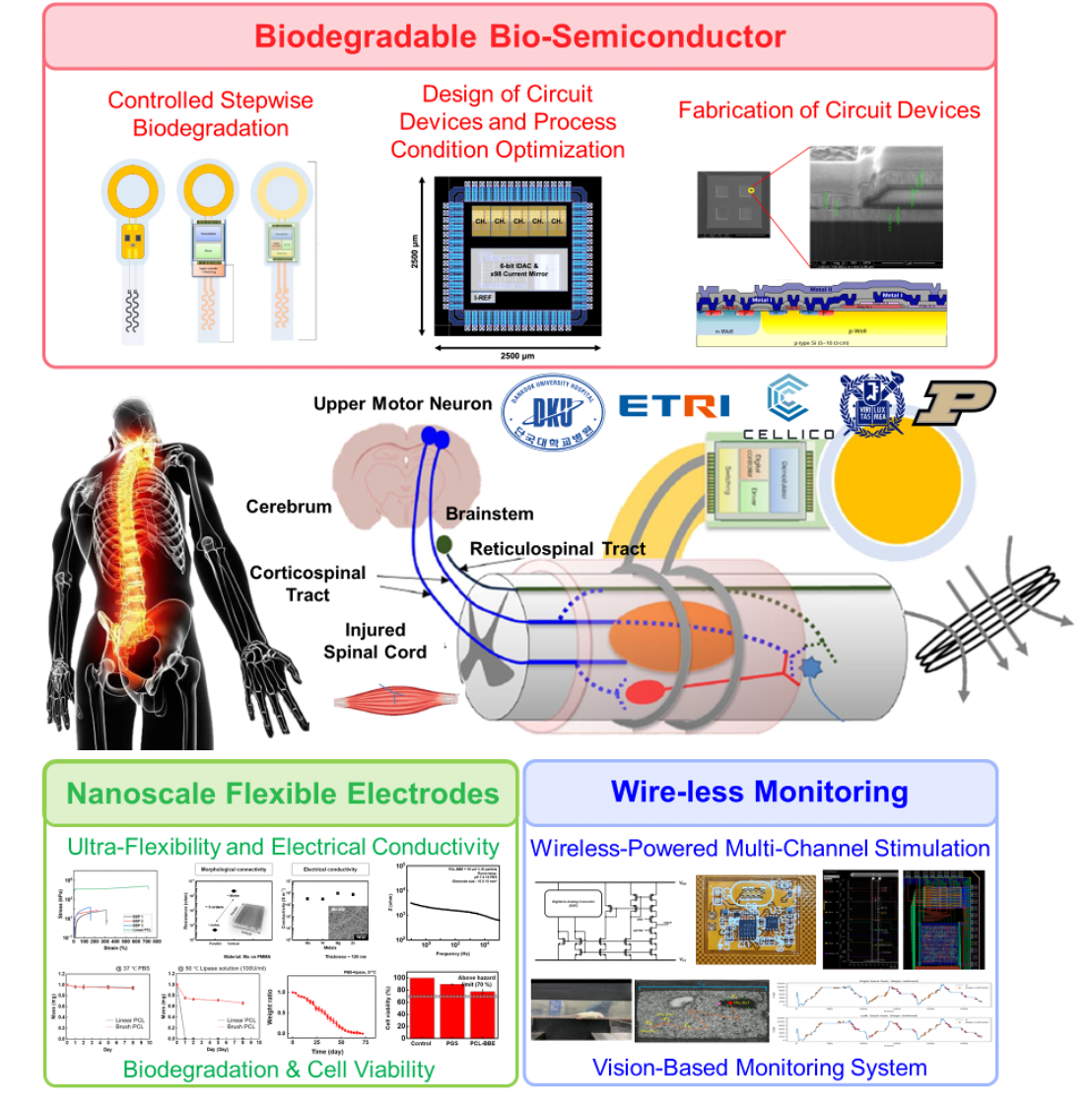

Development of Electroceuticals for Functional Recovery after Spinal Cord Injury Using Biodegradable Semiconductor (Purdue PI: Chi-Hwan Lee)

Spinal cord injury (SCI) leads to severe and often permanent motor impairment because neural regeneration in the injured spinal cord is extremely limited. Existing therapeutic options—including pharmacological treatment, rehabilitation, and epidural electrical stimulation—provide only partial functional recovery and often rely on permanently implanted devices that pose long-term risks and may require removal surgeries. These limitations highlight the need for a new therapeutic approach that is both effective during recovery and free from chronic foreign-body complications.

Spinal cord injury (SCI) leads to severe and often permanent motor impairment because neural regeneration in the injured spinal cord is extremely limited. Existing therapeutic options—including pharmacological treatment, rehabilitation, and epidural electrical stimulation—provide only partial functional recovery and often rely on permanently implanted devices that pose long-term risks and may require removal surgeries. These limitations highlight the need for a new therapeutic approach that is both effective during recovery and free from chronic foreign-body complications.

This project develops a biodegradable semiconductor–based electroceutical platform designed to deliver targeted neural stimulation during a clinically relevant healing period and then naturally resorb in the body. Silicon membrane devices fabricated through wafer-scale transfer printing onto biodegradable polymer substrates achieve high yield and mechanical flexibility while maintaining electrical performance. Based on this device platform, biodegradable stimulator ICs capable of controlling current amplitude, pulse width, and waveform characteristics have been designed and fabricated. Multi-channel wireless stimulation systems integrating telemetry coils, CMOS-based electronics, and embedded controllers enable programmable, real-time neuromodulation.

To enable adaptive therapy, high-resolution behavioral monitoring—including AI-assisted locomotion tracking—is incorporated to evaluate functional recovery and adjust stimulation parameters accordingly. Soft biodegradable materials and electrodes are engineered to match the mechanics of spinal tissue while providing stable conductivity and predictable dissolution in physiological environments. These combined technologies establish a pathway toward transient neuromodulation implants that promote neural regeneration, restore motor function, and eliminate the long-term device burden associated with conventional implantable systems.

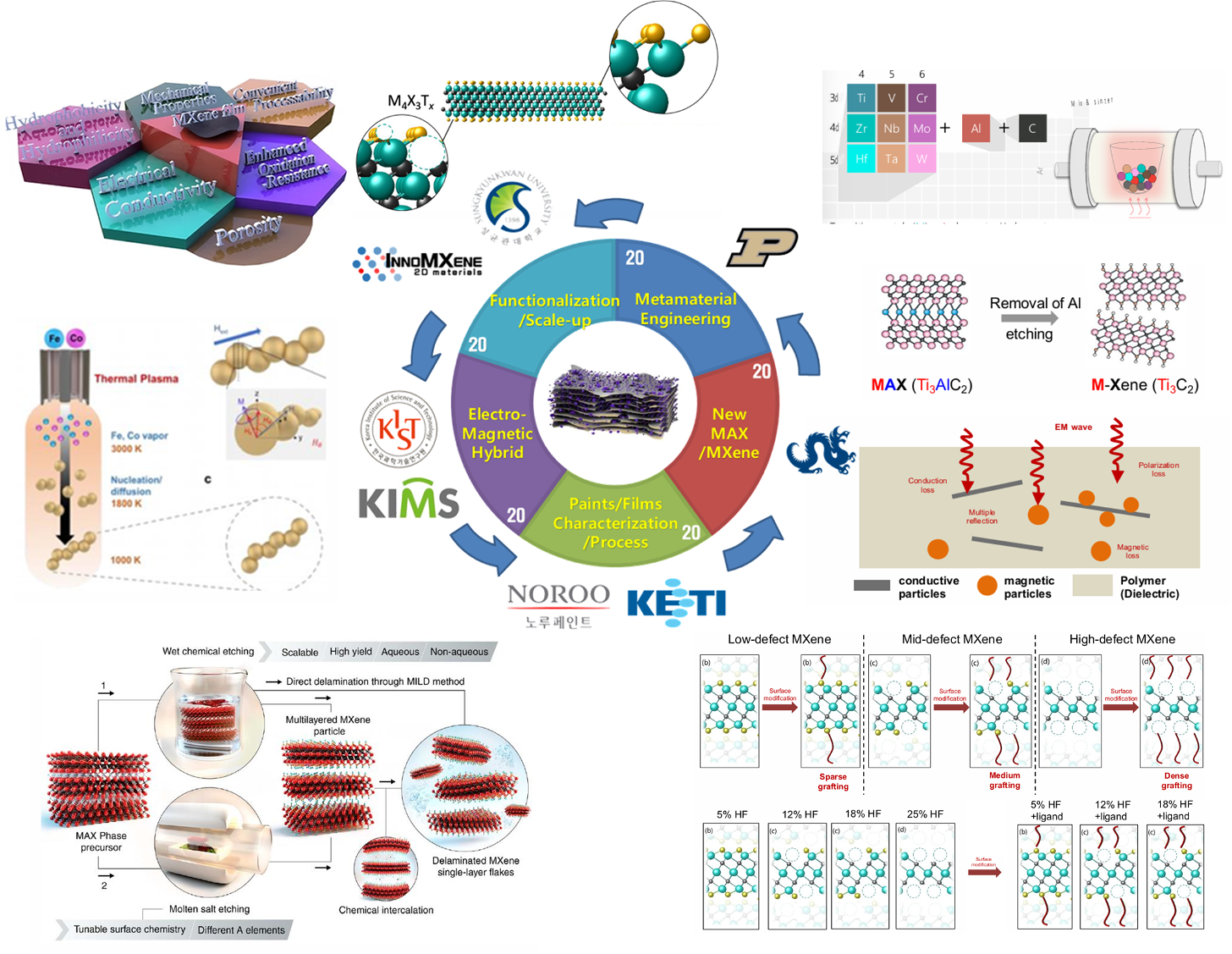

Development of Lightweight Multi-band Electro-magnetic Wave Absorbing Materials Technology for Future Mobility (Purdue PI: Babak Anasori)

Future mobility platforms require materials that can effectively manage electromagnetic interference while remaining lightweight, yet current absorber technologies often rely on bulky carbon-based systems with limited multi-band performance. To overcome these constraints, this project develops advanced electromagnetic wave–absorbing materials based on MXene nanomaterials, engineered through a combined approach of materials design, structural tuning, and scalable coating-process development.

Future mobility platforms require materials that can effectively manage electromagnetic interference while remaining lightweight, yet current absorber technologies often rely on bulky carbon-based systems with limited multi-band performance. To overcome these constraints, this project develops advanced electromagnetic wave–absorbing materials based on MXene nanomaterials, engineered through a combined approach of materials design, structural tuning, and scalable coating-process development.

The research focuses on synthesizing high-performance MXenes with improved electromagnetic attenuation, along with metastructure-inspired and high-entropy absorber architectures that enhance conduction, polarization, and magnetic loss mechanisms across multiple frequency bands. Complementary dielectric–magnetic hybrid composites and high-permeability magnetic materials are also explored to extend absorption bandwidth and reduce material thickness requirements. Through dispersion engineering and flexible coating-process optimization, the project advances lightweight paints and films that maintain stability and absorption efficiency while enabling large-area application suitable for mobility systems.

To ensure manufacturability and performance reliability, the work investigates MXene surface chemistry, defect control, and polymer-interface engineering, identifying how these factors influence dispersion quality and composite dielectric behavior. The resulting MXene-polymer hybrid systems provide tunable multi-band absorption, mechanical flexibility, and compatibility with scalable coating technologies. Overall, this project establishes a pathway toward next-generation lightweight electromagnetic wave–absorbing materials optimized for the demanding operational environments of future mobility platforms.

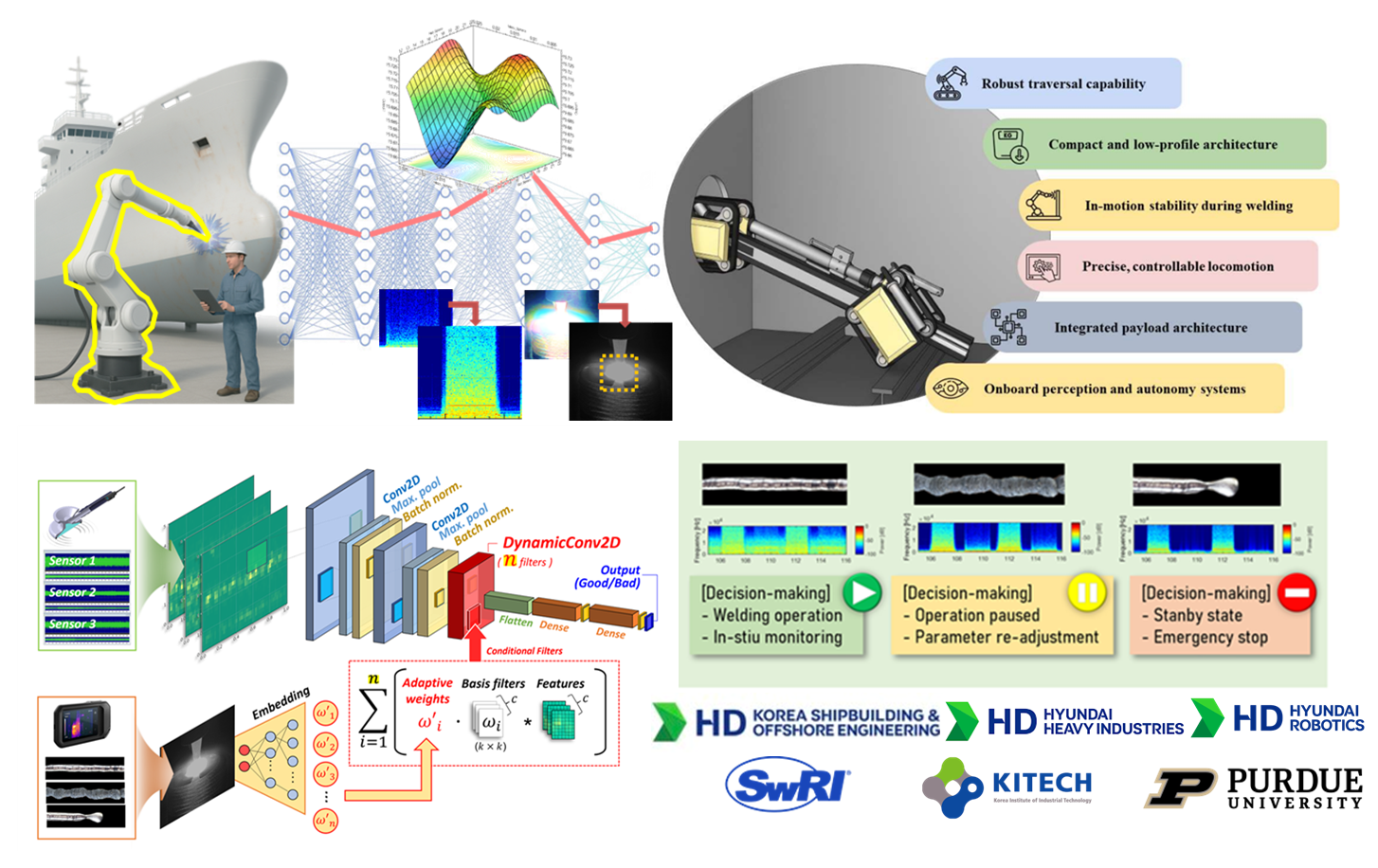

Development of a Lightweight, Real-Time Controlled Welding Robot System for Autonomous Block Welding and Seamless Operation in Confined Ship Structure (Purdue PI: Martin Byung-Guk Jun)

In ship building process, curved hull structures remain one of the largest bottlenecks. Although they represent over 30% of the hull and require more than half of all welding labor, automation has been nearly impossible due to irregular geometries, narrow spaces, and the need for highly skilled manual operation. Despite years of attempts, existing solutions are still limited to flat-plate welding, and no system is capable of autonomous operation inside confined curved blocks. This gap has become a major challenge for productivity, quality consistency, and labor sustainability in global shipyards.

In ship building process, curved hull structures remain one of the largest bottlenecks. Although they represent over 30% of the hull and require more than half of all welding labor, automation has been nearly impossible due to irregular geometries, narrow spaces, and the need for highly skilled manual operation. Despite years of attempts, existing solutions are still limited to flat-plate welding, and no system is capable of autonomous operation inside confined curved blocks. This gap has become a major challenge for productivity, quality consistency, and labor sustainability in global shipyards.

To address this limitation, the project aims to develop a lightweight, mobility-integrated autonomous welding robot system capable of real-time operation within complex 3D ship structures. The system integrates an ultralight 6-DOF welding arm, a compact mobility platform designed to pass through access holes, and coordinated motion control enabling synchronized welding even during robot movement. Using real-time scanning and Scan-N-Plan framework, the robot can automatically generate welding paths on irregular curved surfaces without requiring CAD models. Gap detection and on-the-fly trajectory correction ensure stable operation across various joint shapes and welding positions.

The technology further incorporates AI-based acoustic–vision fusion quality monitoring, developed from Purdue University’s industrial sensing and real-time adaptive control expertise. By analyzing arc sound and video during welding, the system predicts defect occurrence and adjusts parameters through reinforcement learning–based adaptive control. Multi-stage prototypes ranging from ultralight arms to complete curved-block systems will be validated in shipyard environments. Ultimately, this project establishes a next-generation autonomous welding platform that eliminates long-standing automation barriers in confined ship structures and delivers a major leap in shipbuilding productivity.

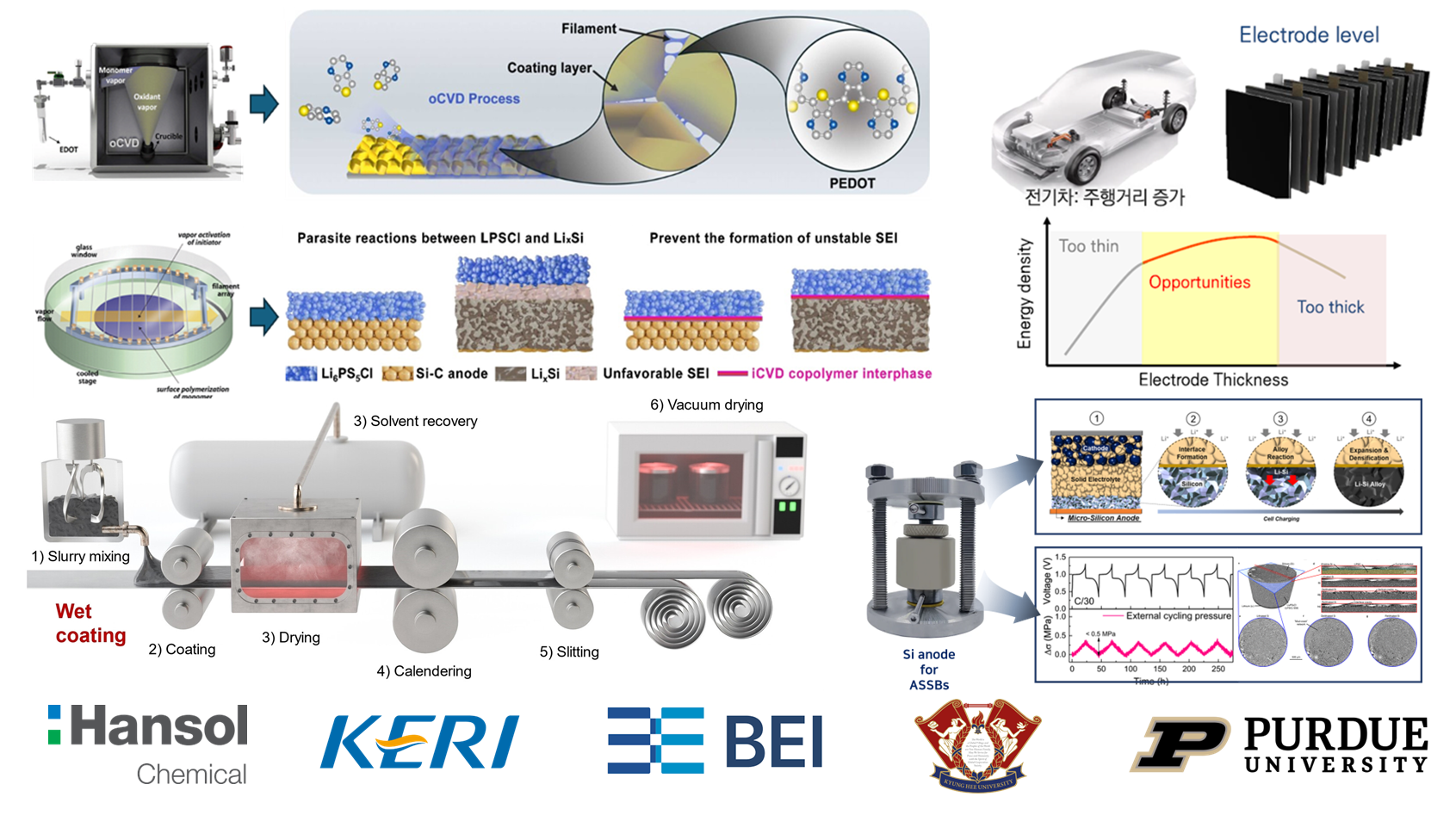

Toward Dry-Processable Silicon Anodes for Solid-State Batteries Exceeding 7 mAh/cm2 via CVD/Polymer Surface Modification (Purdue PI: Sunghwan Lee)

The development of next-generation solid-state batteries faces critical challenges due to the limitations of conventional wet-processed silicon anodes, which suffer from interfacial instability with sulfide solid electrolytes and heavy dependence on conductive additives and binders. These constraints reduce energy density and hinder commercialization. To overcome these barriers, the project focuses on creating a high-capacity silicon–carbon composite anode enabled by CVD-based polymer surface modification and dry-electrode processing technologies. This approach establishes a pathway to scalable solid-state battery manufacturing without relying on solvent-based slurry processes.

The development of next-generation solid-state batteries faces critical challenges due to the limitations of conventional wet-processed silicon anodes, which suffer from interfacial instability with sulfide solid electrolytes and heavy dependence on conductive additives and binders. These constraints reduce energy density and hinder commercialization. To overcome these barriers, the project focuses on creating a high-capacity silicon–carbon composite anode enabled by CVD-based polymer surface modification and dry-electrode processing technologies. This approach establishes a pathway to scalable solid-state battery manufacturing without relying on solvent-based slurry processes.

The research centers on forming uniform nanoscale polymer coatings on silicon particles through conductive polymer chemical vapor deposition, allowing improved interfacial stability, reduced binder usage, and enhanced electronic pathways within the composite. A dry-coating and continuous large-area electrode fabrication method is developed to eliminate solvent handling while enabling high tap-density electrode structures. Additional work targets polymer interlayers that stabilize the interface between the silicon composite anode and sulfide-based solid electrolytes, minimizing interfacial resistance and enabling extended cycle life.

Through integrated optimization of polymer chemistry, electrode architecture, and solid-state cell design, the project aims to demonstrate pouch-cell–level prototypes with high areal capacity and improved durability. The resulting technology significantly simplifies electrode manufacturing, reduces energy consumption, and provides a practical route toward commercial-scale solid-state battery production. By establishing both materials innovation and scalable dry-processing capability, this project positions the silicon–carbon composite anode as a key enabler for future high-energy solid-state battery systems.