It’s nearing 3 p.m. on April 1, 2024, and six graduate students, a research assistant and an associate professor have been watching pressure graphs closely for most of the afternoon. Since the previous summer they’ve been working to fire up a new test tunnel in Purdue’s super-secure Hypersonics and Applied Research Facility (HARF), dealing with impossibly tight tolerances even for a so-called “low-pressure” test.

The qualifiers for this are baffling: Building up the driver reservoir to “just” 1,900 psi, a far cry from its 20,000 psi maximum. A high-speed camera slowed down to “only” 20,000 frames per second, so it can be run continuously. They’re expecting “merely” Mach 7 flow, just a start on the way to its Mach 40 limit.

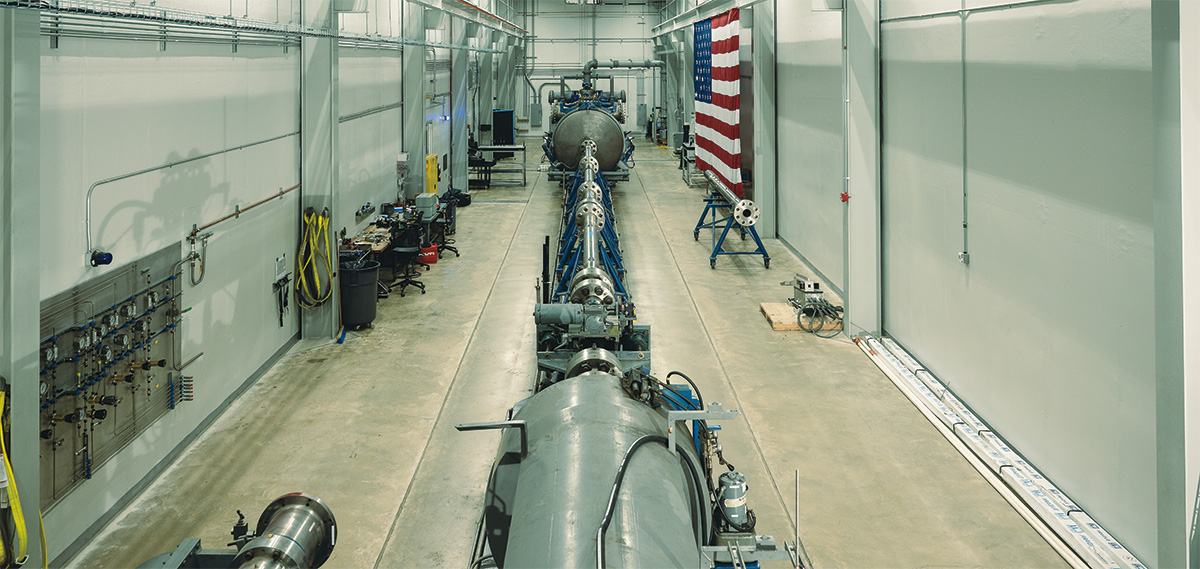

Even when operating so far from maximum, the 6-inch-diameter (2.5 cm) steel shock tube must be perfectly straight — deflecting no more than an eighth of an inch every 30 feet (3 mm every 9.1 meters).

Graduate student Adrian Flores operates an overhead crane to place one of the tube sections that route air from the pressure tanks to the test section of HYPULSE.

As the first test, they don’t expect everything to go perfectly. But it does, nearly. In the final minutes pre-test, they must program a workaround to the filling routine to compensate for a minor leak. Everything else is going exactly to plan.

The team — consisting of grad students Kyle York, Jared Slack, Adrian Flores, Connor Hennessy, Samant Mahipathi, and Grant Dilley, and senior research engineer David Tibbo — double-check everything on their 9-page startup procedure.

It's time. They pass around ear plugs. Hennessy hovers the mouse cursor over the “go” button.

He clicks.

Grant Dilley, a PhD student and research assistant, installs a test model into the test section of the shock tunnel. The model is a 7 degree (half angle) cone with a 6 inch base, with a length of 2 feet. The sharpness of the cone provides a clean shockwave which can be used to calculate the speed of the flow.

A deep hissing emanates through the brick wall. There's a subtle pop, and then a few seconds of a whistling sound. A black-and-white output display from the high-speed camera shows something that resembles the driving rain during a hurricane.

Smiles explode across the faces in the room.

Associate professor and HYPULSE director Joe Jewell and Zucrow Labs managing director Scott Meyer share a high five, and cheer for the team: “Great job, gentlemen!”

They all clap for one another. They clap for themselves. Running back the high-speed video, they click through the frames one by one, watching the flow transition from dirty air to the steady-state test blast. They see what they’ve been hoping for: A distinct shock wave bending downstream of a metal bar in the test section, that they later calculate at Mach 7.

As eager PhDs, the students begin looking for ways to analyze what they see. Jewell tempers their enthusiasm. His own PhD work more than a decade prior, using the T5 Reflected Shock Tunnel at Caltech, gives him perspective. “Be happy you got a Schlieren,” he says, referring to the special optical method used to photograph pressure shockwaves and density gradients — “but don’t claim it was science!”

Reviewing the display screen from an oscilloscope, they also see that each of the three pressure transducers indicated a pressure spike. They cheer again. Not only have they shown that it works, but they’ll also be able to calculate the shock speed and flow conditions from that data, and fine-tune the camera triggering to run it at higher framerates. Now they can submit research proposals.

It’s pure excitement. Until —

“Oh no!” one student says. “It didn’t save the data.”

The room falls silent. Their mouths hang open as they imagine their months of work nearly vanishing. Or picturing what went wrong. Or wondering how long it will be until they can test again.

“April fools?” he says, sheepishly. The room laughs in relief. “Too soon, man!”

A group of people involved in the recommissioning of HYPULSE stand in the lobby of the Hypersonics Applied Research Facility. One of them is holding the burst metal disc that initiated the first test of the device. Front row, left to right: Connor Hennessy, David Tibbo, Kyle York, Grant Dilley. Back row, left to right: Samant Mahipathi, Adrian Flores, Joseph Jewell, Jared Slack, Scott Meyer.

Jokes aside, the first test of Purdue’s HYPULSE reflected shock/expansion tunnel was an unqualified success. But this test, four years in the making, was just a starting point. They verified the pumps, valves, seals, sensors and data collection systems, and identified weaknesses to address on their way to testing at higher levels of pressure and enthalpy. Jewell expects by the end of 2025 that they’ll exceed Mach 25 — orbital velocity.

This system’s original design, shown in yellowed drawings signed by NASA draftsmen, dates back to the 1960s. It was upgraded many times in the decades following as it continued to change hands, finally being donated to Purdue in 2020 by Northrop Grumman.

Jewell’s experience — which includes running the Boeing/AFOSR Mach 6 Quiet Tunnel, a shock tube, and other aerodynamic research equipment at Purdue — informed the construction plans for the HARF building that would house HYPULSE. He led adding upgrades and refinements as the system was installed, making it capable of taking millions of data points per second with modern instrumentation techniques.

Before it was installed in the Hypersonics Applied Research Facility, the HYPULSE had not been operational for years. It was donated to Purdue in 2020 by Northrop Grumman, the last private owner of the device after NASA initially designed it in the 1960s.

That extreme headroom makes it suitable for far more than cutting-edge hypersonic missile systems — its flexibility makes it capable of testing spacecraft that would enter atmospheres other than Earth, or on very high Mach number trajectories returning astronauts from the moon or Mars.

“HYPULSE is versatile because you can put in any gas you want. We can mix up the atmosphere of Titan, or one of the outer planets, or fill it with CO2 to match Mars,” Jewell says.

“This opens up a lot of potential for Purdue. Very few universities have anything like this. We have a huge amount of interest in it,” he adds. “HYPULSE opens up entirely new pathways for hypersonic research.”

After the cheers died down and Jewell had congratulated each of his students, he took a moment to reflect on his progress. Appropriate to the theme of the day, he expressed disappointment — but firmly tongue-in-cheek.

“I’ve been saying for years that we would have this running by the first quarter of 2024,” he says. “Getting it running on April 1, well, it made me a liar by one day.”

Graduate students Adrian Flores and Kyle York insert a burst disk into the double diaphragm section of the tunnel. The double diaphragm uses two scored metal disks as the starting mechanism for the tunnel. When these disks rupture, the high pressure from the driver enters the shock tube and creates an incident shock, thus starting the tunnel. Both disks are replaced every time the tunnel is fired, so this is a very typical scene at Hypulse.