Objective

- Enterprises can benefit from detailed manufacturing / part information

(when needed)

- Leverage already available information to improve product quality

- Increase value in collaborative e-Work networks

- Identification of partsĄŻ attributes for re-workability, re-

manufacturing, and recycling

- DFAD: assembly-oriented design of the product and the assembly/disassembly

design for re-use and remanufacturing; is essential to the life-cycle

engineering approach (Nof and Chen, 2003)

Methodology

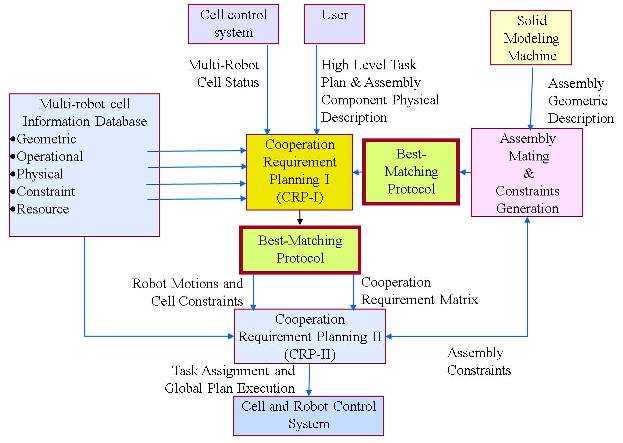

- Enable matching of robot capabilities and tasks to be performed

- CRP-I goals:

- Operational: match tool and fixture to task requirements

and their availability

- Physical: match ability of robot to task requirements

- Geometric: determine capability of robot to execute the

trajectory for assembly

- Extended CRP (ECRP)

- DFA principles enable better assembly planning but do not

guarantee that conflicts and errors do not occur

- ECRP uses the output from the CRP-I and CRP-II to detect

and control conflicts and errors (Nof and Chen, 2003)

- Mcr methodology (Lara and Nof, 2003)

- NEFUSER methodology (Avila-Soria, 1999)

Recent organizations involved

Purdue Technical Assistance Program, IBM, General Motors, Kimberly-Clark Corp.

Sample Publications

Chiam, T. (2004). Modeling and Application of the Best-Matching Protocol. MS thesis, School of Industrial Engineering, Purdue University, West Lafayette, IN, USA.

Kang, H. (1994). Development of Information Exchange Protocols for Distributed Inspection Integration. MS thesis, School of Industrial Engineering, Purdue University, West Lafayette, IN, USA.

Velasquez, J. D., Nof, S. Y. (2008). Integration of Machine-Vision Inspection Information for Best-Matching of Distributed Components and Suppliers, Computers in Industry, 59(1), 69-81.

Velasquez, J. D., Nof, S. Y. (2008). A Best-Matching Protocol for Collaborative e-Work and e-Manufacturing, International Journal of Computer Integrated Manufacturing, 21(8), 943-956.

Velasquez, J. D., Nof, S. Y. (2007). A Best Matching Protocol for Supplier Selection in e-Work Networks, Proceedings of the 19th International Conference on Production Research.

Velasquez, J. D., Nof, S. Y. (2007). Best Matching Protocol for Cooperation Requirement Planning in Distributed Assembly Networks, Intelligent Assembly and Disassembly Conference IAD'07.

Contact

Juan D. Velasquez (jvelasqu@purdue.edu)

|