Generalized Intelligent Grinding Advisory System

Generalized Intelligent Grinding Advisory System  Generalized Intelligent Grinding Advisory System

Generalized Intelligent Grinding Advisory System

![]() What is it?

What is it?

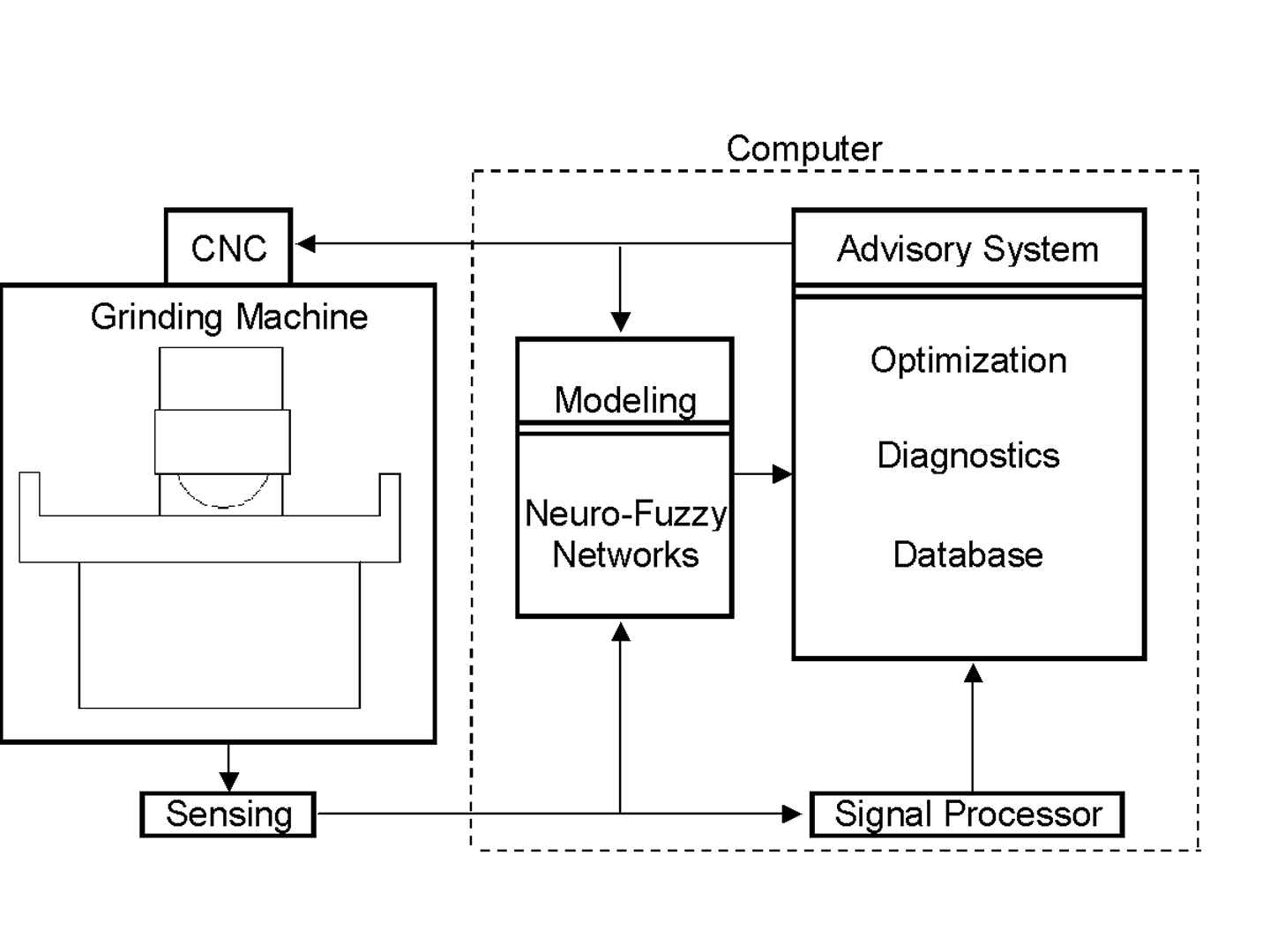

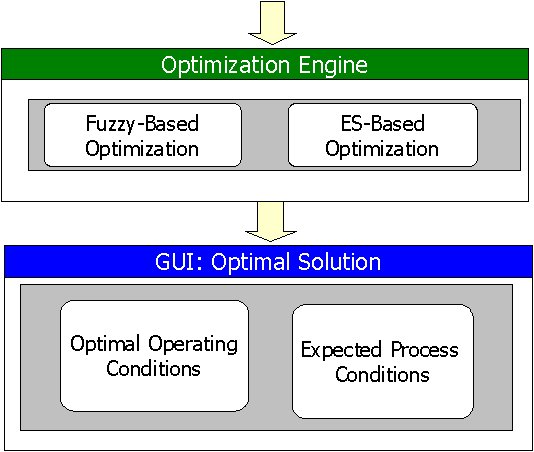

The GIGAS utilizes three different types of knowledge, i.e., analytical models, empirical data and heuristic rules, and provides optimal operating conditions based on a novel optimization scheme. It also provides the capabilities of autonomously learning complex manufacturing processes. The control scheme is supervisory in nature and can be incorporated into a PC-based CNC or can run on a stand alone PC. Currently GIGAS can optimize surface, traverse OD/ID, plunge grinding and centerless grinding processes. Additional grinding processes are being included as needs arise. The system is capable of providing optimal conditions under various objectives for achieving desired process conditions, cycle time minimization and cost minimization.

![]() Architecture

Architecture

The advisory system can handle three types of grinding processes: surface grinding, internal and external ID/OD grinding, plunge and centerless grinding processes. They share common generalized model building capability and inference engines.

|

|

|

Overall architecture of generalized grinding

advisory system

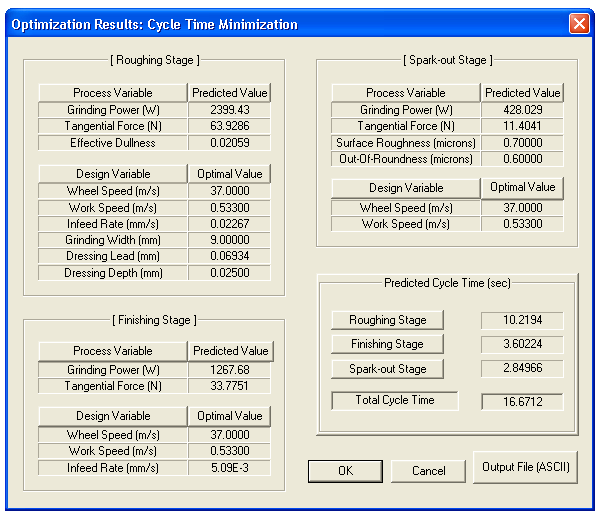

![]() The sample

output from the GIGAS (for Cycle time minimization).

The sample

output from the GIGAS (for Cycle time minimization).

![]()

[ Welcome ] [ Research

] [ Education ] [ Laboratories ] [ Collaboration

] [ People ]

© 2000 Purdue ME Manufacturing Laboratories

Last modified by Brian Bolek, 26 February 2000.