We are carrying out various micromachining projects using both mechanical machine tools and ultrashort pulsed lasers.

The research topics are being carried out include:

mechanical micromachining using a three-axis machining system with micro endmills (100-300 microns in diameter)

laser-assisted micromachining

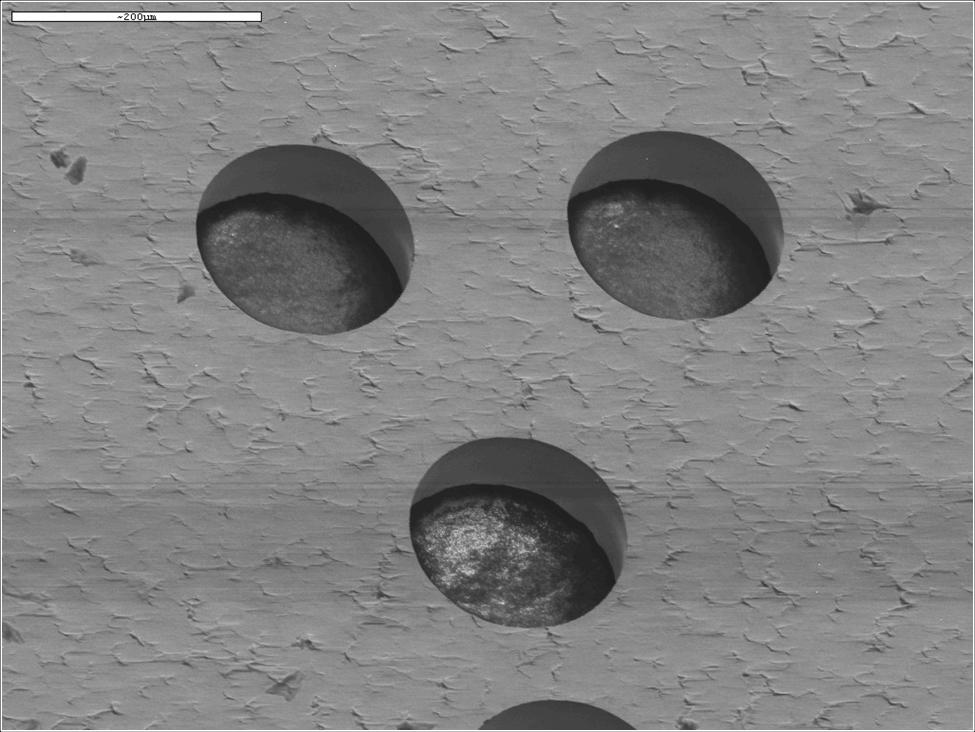

laser micro hole drilling

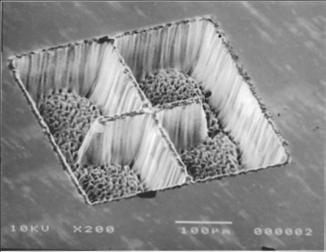

laser micromachining using a picosecond laser

laser micromachining of glasses using a femtosecond laser

![]()

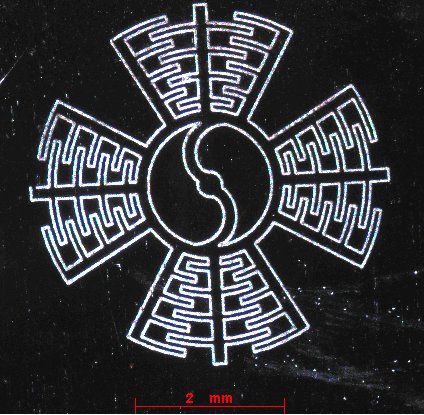

Various micro features can be created by mechanical micro milling with end mills ranging from 100 microns to 300 microns in diameter.

|

|

|

|

|

micro walls machined using a 100 micron endmill on a stainless 316 workpiece. The walls are approximately 15 microns thick and 90 microns tall. |

An array of micro holes drilled on a steel plate |

The following features are machined by a pico-second laser available in the lab. The lower left pattern is a micro channel, which was machined in about 0.5 seconds, while the lower right picture shows the holes of 180 microns drilled on molybdenum.

|

|

|

|

|

micro accelerometer channels machined by a picosecond laser in 0.374 seconds

|

180 micron holes drilled on molybdenum |

Ti6Al4V – Thin Frame Frame thickness: 10 microns, depth: 75 microns. |

Micro via hole drilled on a SiC/SiC ceramic matrix composite |

[ Welcome ] [ Research ] [ Education

] [ Laboratories ] [ Collaboration ]

© 2000 Purdue ME Manufacturing Laboratories