An award-winning Purdue University technology is showing increasing promise in helping to detect foodborne pathogens in real time. It’s a problem that the Centers for Disease Control and Prevention estimates sickens about 48 million people and kills about 3,000 each year in the United States. It is also a problem gaining more attention because of an deadly salmonella outbreaks in the U.S.

Michael Ladisch, Distinguished Professor of Agricultural and Biological Engineering; Eduardo Ximenes, a senior associate bioprocess research scientist at Purdue’s Laboratory of Renewable Resources Engineering (LORRE); and their research team won the grand prize in the 2014 FDA Food Safety Challenge for their automated filtration technology to detect salmonella. They have now enhanced the technology to allow multiple samples to be tested at the same time and to test for other foodborne illnesses, such as E. coli O157:H7.

“Our technology continues to make giant leaps in health and preventing more people from being sickened by foodborne illnesses,” Ladisch says.

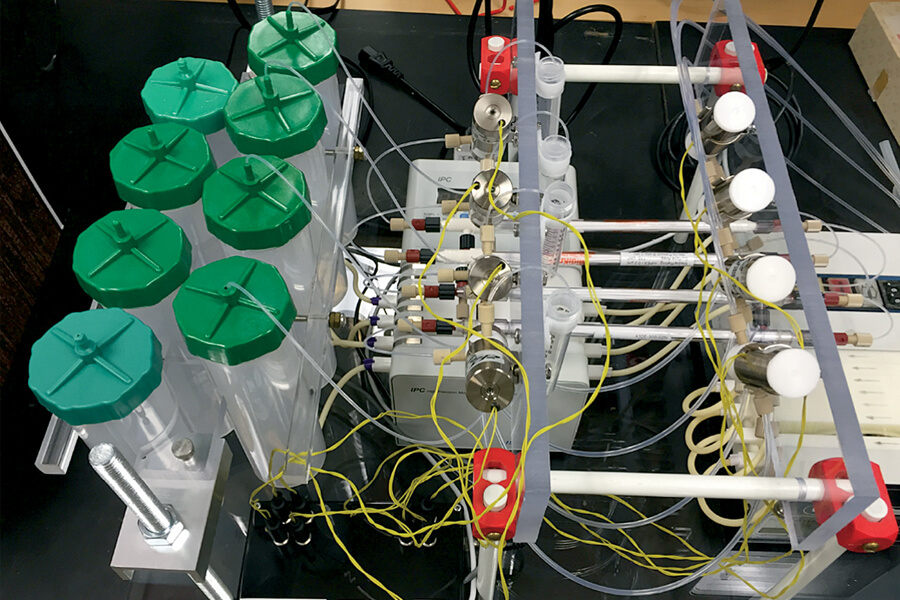

Purdue’s technology involves using a biochip to collect and analyze microbes in food samples. The innovation also uses enzyme formulations and software to analyze food microorganisms within four hours, instead of the current two to four days it typically takes.

Manufacturers in the United States spend nearly $3 billion each year on food safety tests. Yet a major challenge remains: The ability to test samples quickly to reduce detection time and prevent more people from becoming ill.

“The other great advancement we have made since 2014 is the ability to test up to four samples at once, and we are continuing to increase that number,” Ximenes says. “A foodborne illness outbreak results in hundreds of samples being sent to the FDA each day, so making the process faster is critically important.”

The researchers have worked with the Purdue Office of Technology Commercialization on patents for their innovation. They are continuing to look for partners to test and commercialize their technology.

LORRE Research Collaboration

LORRE carries out fundamental research that impacts engineering and agricultural research at Purdue and contributes to new knowledge for the engineering of renewable resources. The research draws on expertise, infrastructure and fundamental science in a range of areas that are combined into multi-disciplinary problem-solving approaches. These approaches provide LORRE students and researchers experiences that integrate discovery, learning and engagement through the practice of bioprocess engineering.

Since its founding in 1978, the laboratory has carried out its work in bioenergy, biofuels/bioproducts, bioseparations, food safety and bioprocessing, while educating students, performing bioprocess research and translating its discoveries to the industry.