New process targets improvements for manufacturing across several growing industries

Sharpie or glue stick make cutting "gummy" metals easier

DOE Funds Research On Making Energy-Efficient Sheet Metals

Purdue University engineers are getting a $1.5 million federal grant to begin studying the new process and its applications this summer.

Purdue News: Research solves centuries-old riddle of Prince Rupert’s drops

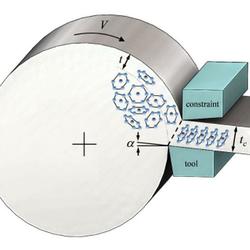

The Center for Materials Processing and Tribology is a cooperative world-class cross-disciplinary research program involving the Schools of Industrial Engineering and Materials Engineering. The Center was established in 1999 with funds from the Purdue Academic Re-Investment Program. Prior to this, the Center was one of the major thrust areas within the National Science Foundation (NSF) Engineering Research Centers for Intelligent Manufacturing Systems (1989-1994) and Collaborative Manufacturing (1994-1999).

The principal research thrusts of the Center are Manufacturing and Materials Processes, Advanced Structural Materials, Tribology of Material Systems for Enhanced Component Performance, and System Models that Integrate Process Parameters with Product Performance. The Center faculty research activities have been supported by companies, the NSF, and Federal agencies. The Center operates world-class research laboratories in Manufacturing Processes, Metrology, Tribology and Materials Characterization. More than 140 M.S. and Ph.D students have graduated from the Center since 1992.