|

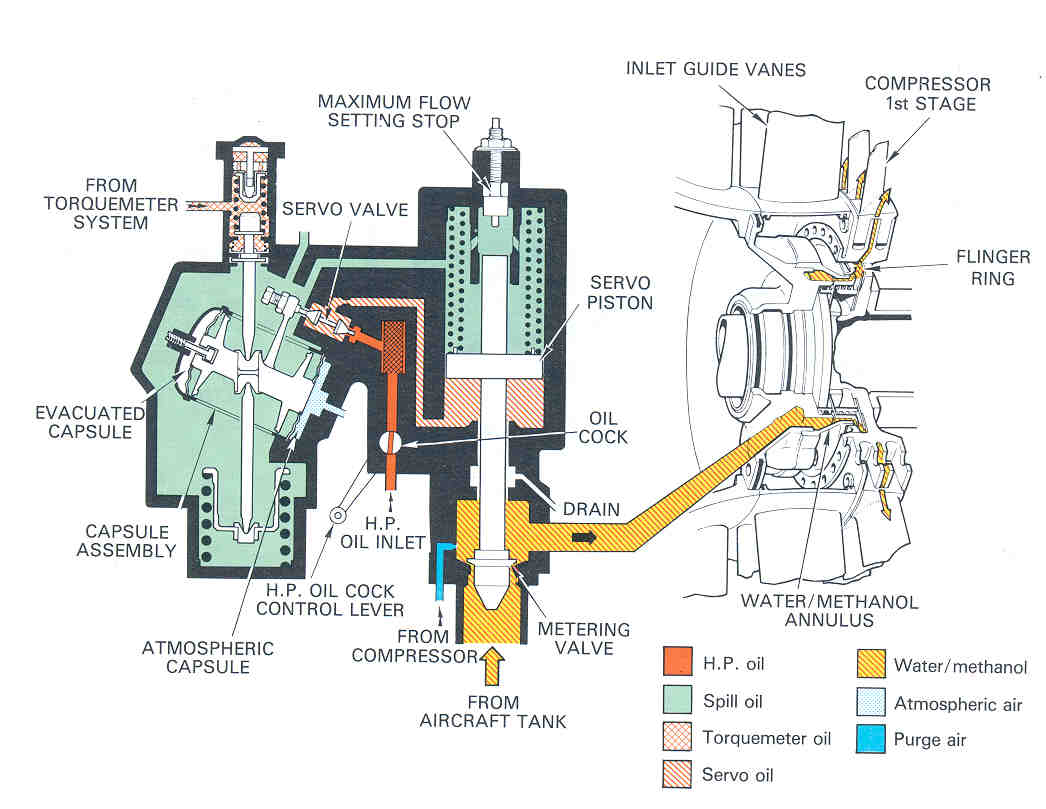

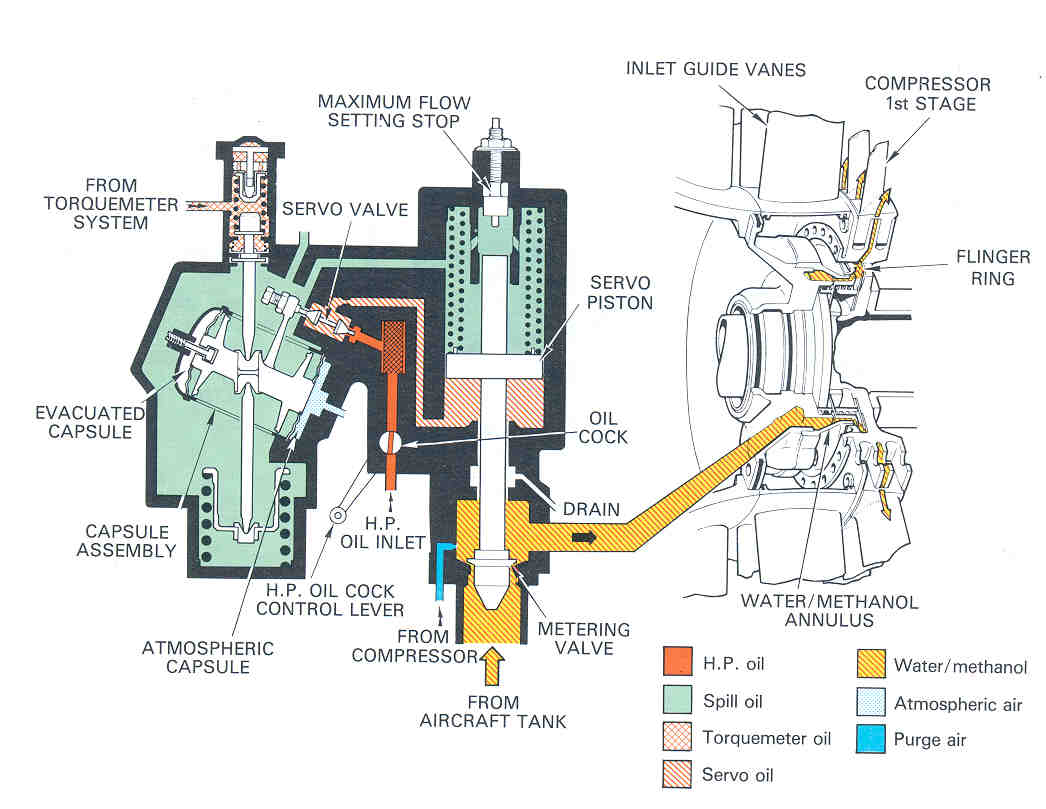

When the water/coolant is sprayed into the compressor inlet, the

temperature of the air is reduced, increasing the density of the

compressor inlet air, and consequently, the thrust is increased.

The system shown to the left is a typical compressor inlet injection

system. When switched on, the coolant is pumped to a control unit which

measures the flow of the mixture to the compressor inlet. A servo valve

regulates the supply of oil using engine oil as an operating medium. The

degree of the servo valve opening is sensitive to propeller shaft torque

oil pressure and to atmospheric air pressure. |

|

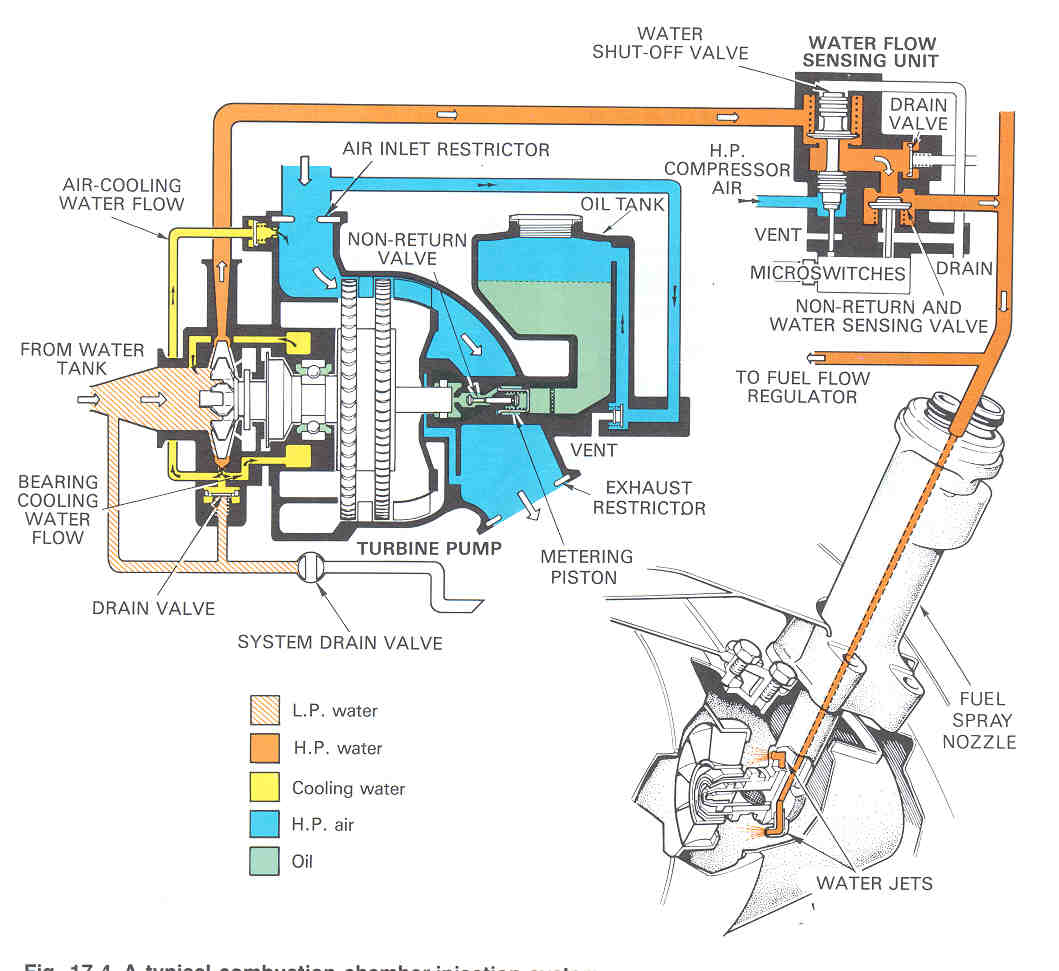

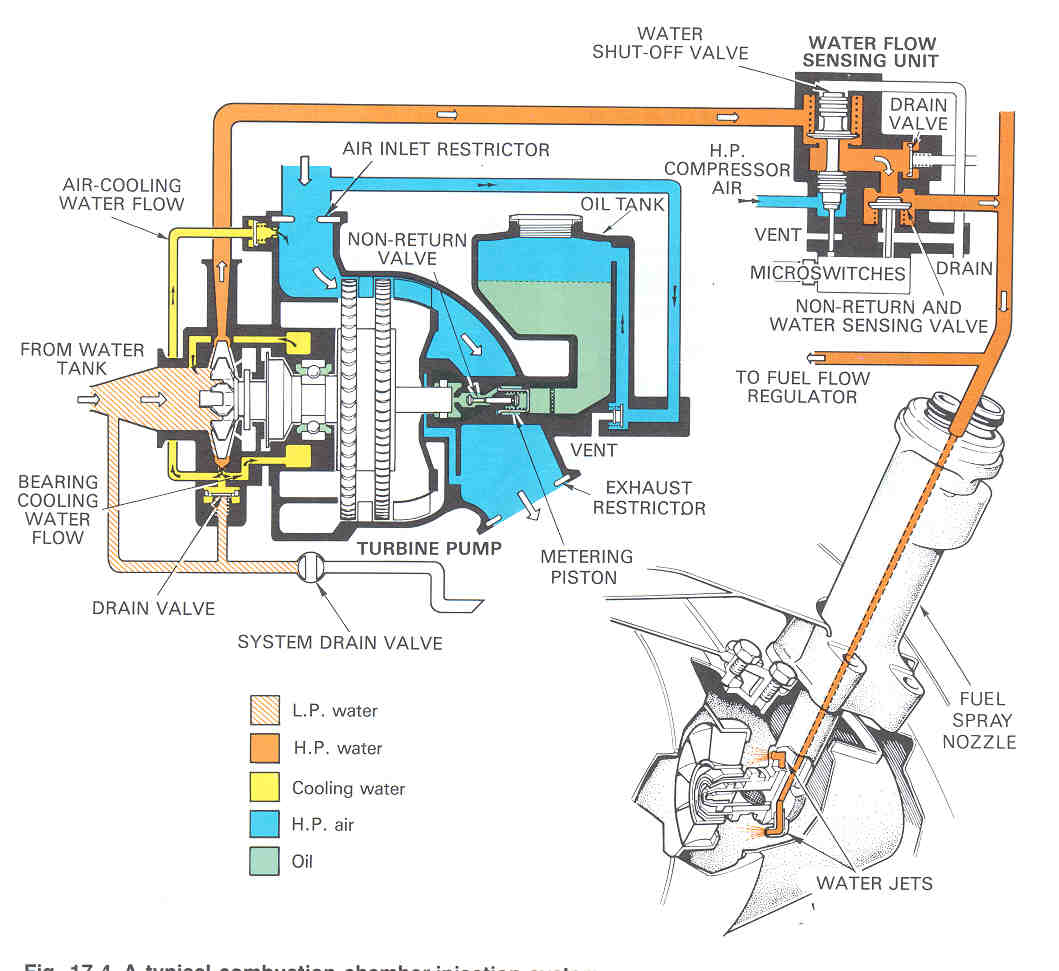

The injection of coolant into the combustion chamber inlet

increases the mass flow rate through the turbine. The pressure and

temperature drop across the turbine results in an increase in

pressure in the jet pipe, giving additional thrust. Also, the

consequent reduction in turbine inlet temperature allows the fuel

system to increase the fuel flow to a valve giving an increase in

rotational speed of the engine. This provides even more additional

thrust.

The system shown is a typical combustion chamber injection system.

Coolant flows to an air-driven turbine pump sending it to a water

flow sensing unit. From there it passes to each fuel spray nozzle

and is sprayed onto the flame tube swirl vanes. This cools the air

passing into the combustion zone. The fuel control system senses the

water pressure, which will automatically reset the engine speed

governer to give a higher maximum engine speed. The water flow

sensing unit will only open when the difference between the

compressor delivery air pressure and the water pressure is correct. |

Back to the Purdue AAE Propulsion main page.

Back to the Purdue AAE Propulsion main page.

Back to the Turbine Engine Basics page.

Back to the Turbine Engine Basics page.

Back to the Purdue AAE Propulsion main page.

Back to the Purdue AAE Propulsion main page.

Back to the Turbine Engine Basics page.

Back to the Turbine Engine Basics page.