SOP 11. Ventilation Fan Monitoring

April 2002

Introduction

This SOP describes the

procedures to follow for the continuous determination of ventilation rate in

mechanically ventilated livestock and poultry housing units. The method used

for evaluating housing ventilation rate will be the Fan Curve Method (FCM). In

this method, the status of fans is monitored (on/off), the static pressure is

monitored across a fan or fan bank, and the appropriate fan calibration data is

used to determine airflow rate delivery.

Equipment Needed

1. FANS monitoring system

2. SETRA Model 267 or Model

267MR static pressure sensor or equivalent

3. SETRA Model ______ power

supply

4. Fan status limit switches Telemecanique Model XCK-P106 (Grainger

Model 4B799)

(18.5 in-oz activating

torque)

5. NEMA 4X enclosure

6. Miscellaneous wiring

circuitry

Procedures

The FANS unit is to be calibrated as per BESS

Laboratories (University of Illinois-Urbana Champaign). Once calibrated, the

FANS unit becomes the calibrated sensor from which to calibrate all operating

fans under test.

All fans in a building will be calibrated a

minimum of three times in a calendar year. All calibration work in a housing

unit will be conducted after a close-out, once before fans are cleaned and once

after fans are cleaned. Each fan tested will be tested twice, separated by a

15-minute interval with simultaneous measurements of static pressure. The

average airflow delivery rate for each fan will be recorded, along with the

average static pressure measurement. This airflow versus static pressure will

be used in future calculations to determine airflow delivery rate. For each fan

a set of data will exist for dirty versus cleaned. Three static pressure levels

will be tested by artificially adjusting the fresh-air intake system. Static

pressures near 5, 25, and 45 Pa (0.02, 0.10, and 0.18 in wg) will be tested. A

linear regression equation will be developed to determine the fan curve for

each fan, both cleaned and dirty.

Fan Status Monitoring

The operation status for all fans in a

housing unit will need to be known. It is recommended that changes or

interception of signals from the existing fan control system not be used. Fan

status will be determined using limit switches either attached to existing fan

shutters or configured as a sail-switch.

If attached to fan shutters, whisker limit

switches are recommended. An example set-up using whisker limit switches

(Grainger Model 4B799) is shown below:

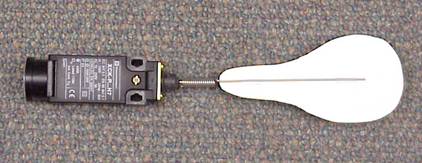

An alternative whisker switch

arrangement for fan airflow activation configured as a sail switch is shown

below (Grainger Model 4B804):

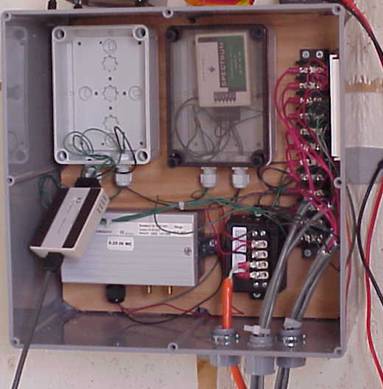

Field Installation

It is recommended that a NEMA 4X enclosure be installed in each barn to

provide the necessary wiring connections for all limit switches and the static

pressure sensor. An example enclosure and wiring connections are shown below:

Limit Switch Wiring

A 2-conductor shielded 18 or 20 gage cable is

recommended for each limit switch. The static pressure power supply (SETRA

Model ______) delivers approximately 24vdc to the SETRA Model 267 (or 267MR)

static pressure sensor and can be used to provide the necessary power to record

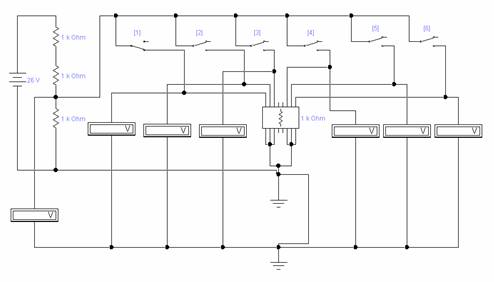

limit switch operation. Two alternatives exist for wiring the limit switches. In

the first method, the voltage sensed from the fan sensor array will vary as the

number of operating fans varies. This method requires that the fan sensor

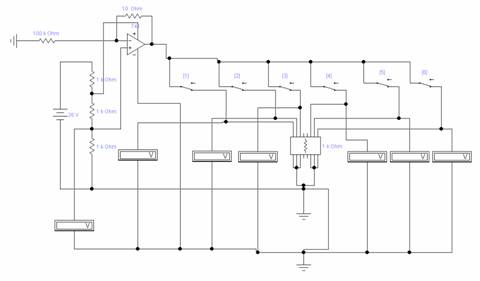

switches be recorded as true analog inputs. A second method yields a true

TTL-compatible signal requiring only that a digital input signal be recorded. The

first method utilizes more expensive analog input data acquisition equipment

but does give the user a better chance of determining proper operation of the

limit switches. Wiring examples are given below:

Method 1. Variable analog output with sequential fans in operation

Fan On: VDC

out: Fan On: VDC out:

0 0.0 1,2,3,4 2.4

1 5.2 1,2,3,4,5 2.0

1,2 3.7 1,2,3,4,5,6 1.7

1,2,3 2.9

Method 2. True binary output signal

Fan On: VDC out: Fan On: VDC

out:

0 0.0 1,2,3,4 5.2

1 5.2 1,2,3,4,5 5.0

1,2 5.2 1,2,3,4,5,6 4.2

1,2,3 5.2

Ventilation Rate Calculations

Airflow delivery rate for a housing unit will

be determined by:

1. Measuring static pressure

2. Recording fan status

3. Apply FANS calibration data

to operating fans

4. Determine housing unit

airflow delivery rate using:

Q = S { FCFi * Fani * (mi*DP + bi) } for Fans i = 1 to n

where

Q =

airflow delivery rate, m3/h (ft3/min)

FCFi = fan cleanliness factor (maximum=1.0, minimum determined from

dirty/clean fan performance)

Fani = individual fan status (0 = off, 1 = on)

DP = static pressure difference between room and outside, Pa (in

wg)

mi =

slope for regression equation developed using FANS, m3/hr-Pa (ft3/min-in

wg)

bi =

intercept for regression equation developed using FANS, m3/hr (ft3/min)

The

Fan Cleanliness Factor (FCF) is an estimate of the effect on airflow delivery

of dust build-up on fan blades, shutters, and grills. When cleaned at the start

of a grow-out period, the FCF=1.0. The FCF during the growth period will be

estimated using the following equation:

FCFi

= (1-EFi) * {(We – W) / (We – Ws)} + EFi

where

We =

ending animal weight, kg (lbs)

Ws =

beginning animal weight, kg (lbs)

W =

current animal weight, kg (lbs)

EFi = fan efficiency factor as determined by dirty versus cleaned

fan data

=

1.0 for cleaned fan

= a factor determined by the

difference in airflow delivery for a dirty versus cleaned fan