Pesticide and Fuel Storage and Management Problem

Due November 7

10 Points

Using the pesticide storage and handling assessment software module and the fuel storage assessment software module, evaluate the pesticide storage and handling practices and the fuel storage practices described below. Once you have completed the evaluations, make recommendations concerning the changes (management or facilities) you would make. Evaluate the situation considering your changes.

You should turn in the evaluation reports for the current conditions and for the proposed conditions (at least the key problems identified by the software). Provide a brief report explaining your recommended changes and the impact they would likely have.

Site Description

The farm is located in central Indiana and is comprised of 822 acres which are at 8 locations within a 6 mile radius of the farmstead. Surrounding the farmstead are 100 acres of row crops and 32 acres of pasture.

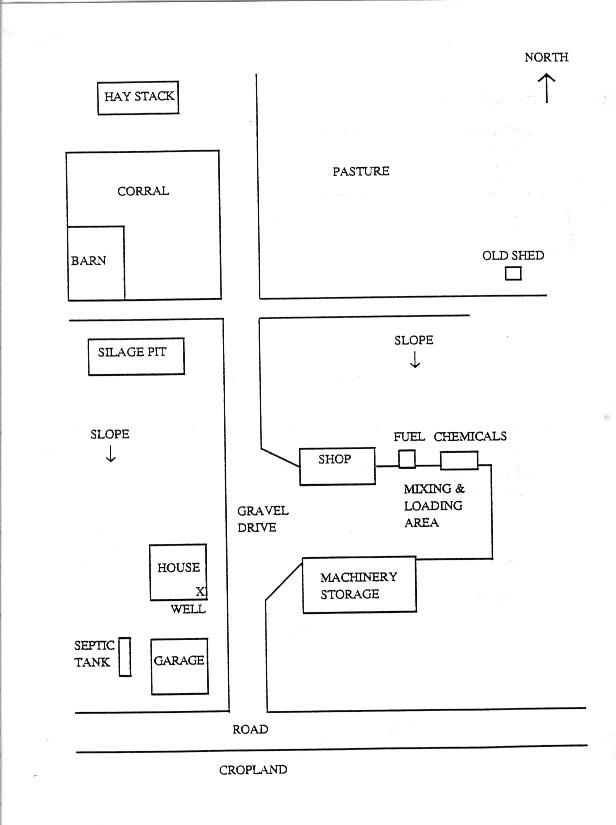

In addition to the row crops, the farm operation has 65 beef cows and 2 bulls. The livestock are located at the farmstead and are located in the pasture and the barn and corral (shown on figure below).

The farmstead has loamy soil (medium texture and well drained) that slopes at 2% to the south. The subsoil is finer and extends to approximately 30 feet. The water table is normally 65 feet below the ground surface. The old shed in the pasture (see figure) contains on old, unused, open dug well.

The well that is currently used is located in the southeast corner of the house basement and was installed in 1961. The well is 100 feet deep, entirely cased, and has a screened inlet. A water pressure tank is located in the basement next to the well.

A 800 gallon diesel storage tank (steel tank painted white) was installed 20 years ago at its present location (see figure). There are no other fuel storage tanks at the farmstead. The piping for the tank is not pressurized. Spill and overflow protection for the fuel tank are not provided although the farmer has been considering a dike around the fuel tank. Inventory control, testing or monitoring are not performed. The tank was installed to industry standards at the time it was installed. The fuel tank is located in a small building for the fuel tank and other petroleum products. As shown on the figure, this building is located near the shop and pesticide storage facility (approximately 35 feet from each). As a result of recent thefts in the area, the fuel building is kept locked.

Sometimes there are 75 gallons of atrazine and 100 gallons of Lasso II (alachlor) (both are herbicides) stored in liquid form in the pesticide storage area. Herbicides are purchased at a local dealer and only stored for a few weeks per year in the pesticide storage shed, thus containers are new and labels are complete and easily read. The pesticide storage shed has a gravel floor and is kept locked because of recent thefts in the area. The pesticide mixing and loading area is a concrete pad (no curbs) near the pesticide storage shed. A hydrant (no anti-backflow device) is located near the pesticide storage shed that is used to provide water for pesticide mixing. When mixing pesticides, the hose is kept outside the tank and all operations are supervised continuously. Plastic containers of pesticides are brought from the pesticide storage shed and hand poured into the sprayer tank. The tank is designed so pesticides can be easily poured into it. Containers are triple rinsed and returned to the pesticide supplier. Leftover sprayer tank rinsate and pesticide container rinsate are sprayed on crops in fields (far from well).

Note: make assumptions in describing the site in the risk assessment software as necessary.

Figure 1. Farmstead Layout