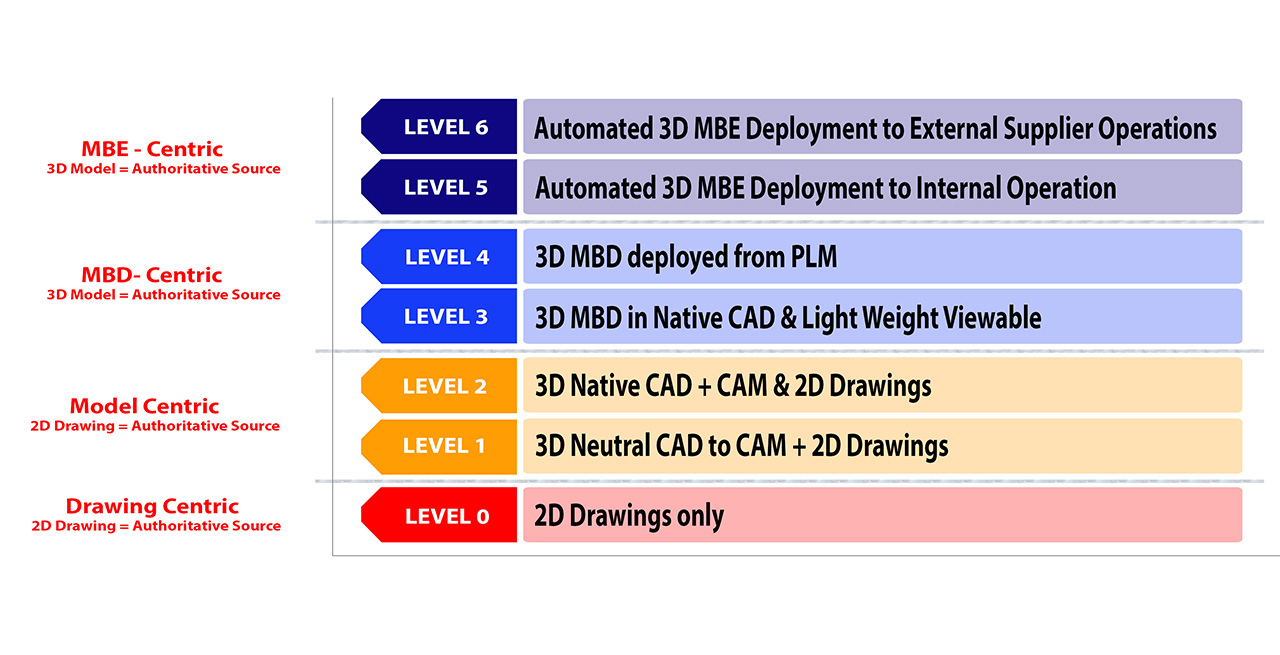

Increase in Quality

- 3D models are less ambiguous than 2D drawings

- Removes drawing-to-model discrepancy

- Manipulates the 3D model directly for clarity

Faster Development

- Accelerates the handling of engineering change orders when design changes are made

- Reduces time required to create manufacturing documentation

Reduction in Cost

- Boeing reported a 50% reduction in fabrication costs & 30% reduction in assembly hours

- Toyota documented a 50% reduction in tooling design and fabrication