Small Diameter Horizontal Two-Phase Flow

Research Supported by Bettis Atomic Power Laboratory

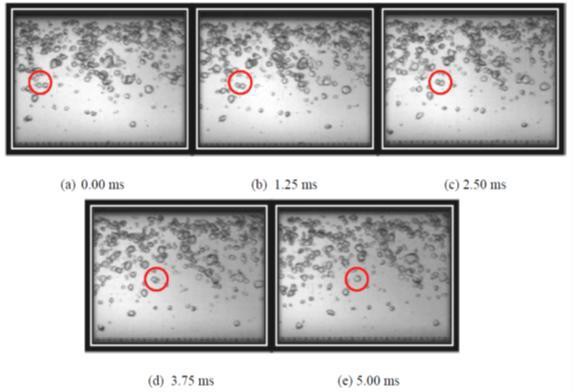

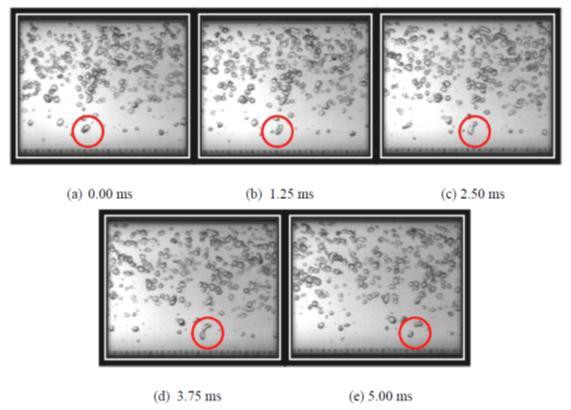

In order to develop and validate Multi-phase Computational Fluid Dynamics (MCFD) codes, an extensive database of two-phase flow information is required for various flow regimes, geometries, and orientations. Many two-phase flow experiments have been performed in vertical flow channel geometries, and thus a substantial number of databases exist to benchmark MCFD approaches in such conditions. However, there are few databases of local two-phase flow parameters acquired in straight horizontal flow channels available that are suitable for comparisons with MCFD and the development of multi-phase closure models. The present work establishes a horizontal, adiabatic, air-water, two-phase flow test facility to: (1) perform detailed flow visualizations, (2) study the interfacial structures and flow regime transitions, and (3) identify gas-phase interactions in air-water horizontal two-phase flow in relation to future interfacial area transport modeling efforts. Figures 1 and 2 highlight two of the bubble interaction mechanisms: turbulence impact breakup and random collision coalescence.

The test facility is designed to be capable of performing experiments in a comprehensive range of horizontal two-phase flow conditions including bubbly, plug, slug, stratified, stratified-wavy, and annular flow regimes. The test section is desiged to provide an ideal condition for flow visualization and for the application of optical instrumentation. A high speed movie camera capable of capturing images at up to 32,000 frames per second is available and will be employed to perform flow visualization studies. In order to achieve a fully developed horizontal two-phase flow, clear acrylic pipes with 3.81 cm inner diameter are employed as the test section, which provide a total development length of more than 200 diameters.

The purpose of the first portion of this research is to perform a scoping experiment to study the effects of break angle and break length-to-diameter ratio (L/D) on the exchange rate during the postulated scenario. Here, water and brine are used as simulant fluids, and flow visualization and density measurement experiments have been performed. The exchange rate is expressed in terms of a non-dimensional Froude number which scales the inertia with respect to the buoyancy. The results obtained are compared with previous studies as shown below.