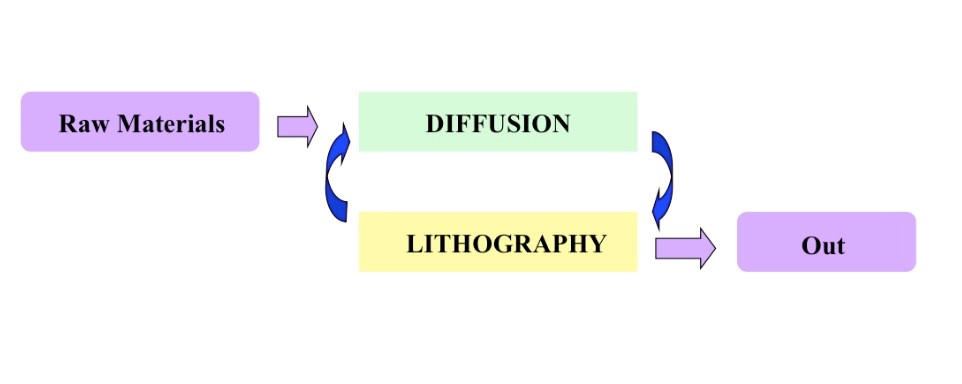

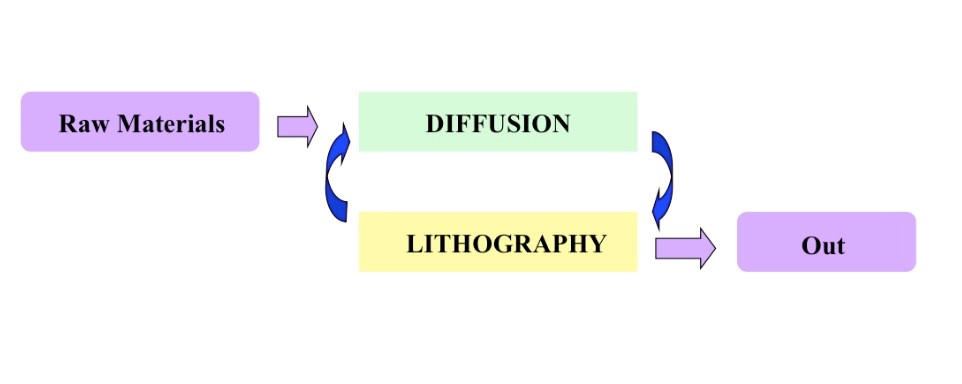

This is a semiconductor manufacturing system. In our simplified version indicated in Figure 1, the production process consists of two basic steps, diffusion and lithography. Sub-steps of the system are indicated in Figure 2.

Figure 1 (Schematic Diagram)

Raw material will be released in cassettes at the rate of 1 cassette/hour, 7 days per week, 8-hours per day. The raw material will begin at the diffusion process, and after diffusion it proceeds to the lithography process. The diffusion and lithography then alternate until the product completes processing. The movement of material from the end of diffusion to the start of lithography (or vice versa) will be handled by an AGV (Automatic Guided Vehicle) or a conveyor. The release of the raw material, the processing of material at each station and the transportation between diffusion and lithography steps are all modeled as exponentially distributed random variables.

Figure 2 (Schematic Diagram)

In this example, data on anticipated product mix and material handling requirement are provided in Table 4. Mean processing time per cassette for each step (hours) and cost of machines for all available machines and transporters are provided in Table 5. Factor description and levels (Unit Number) are provided in Table 6.