Research

Transport Phenomena in Multi-Scale, Heterogeneous Materials & Systems

Thermal Interface Materials (TIMs) with High Thermal Conductivity Particles

Thermal Interface Materials (TIMs) with High Thermal Conductivity Particles

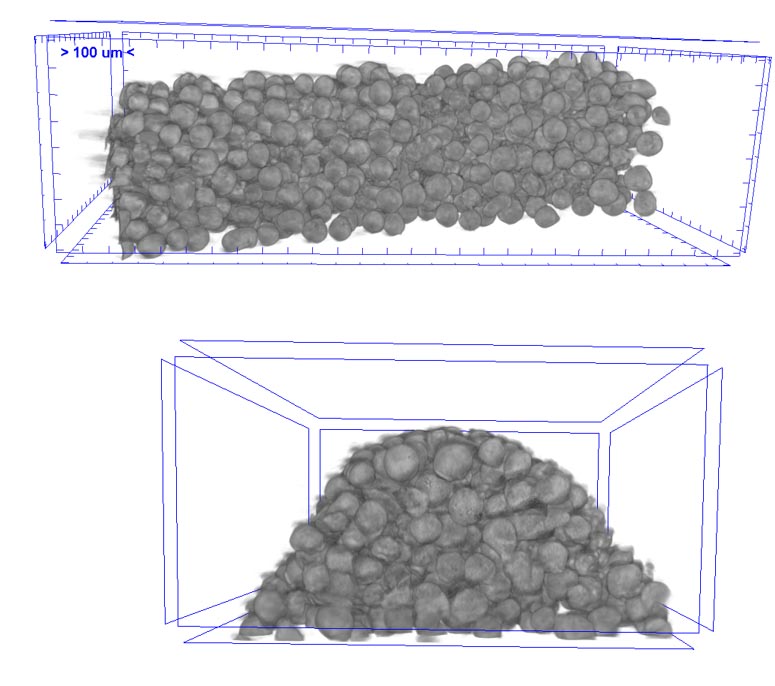

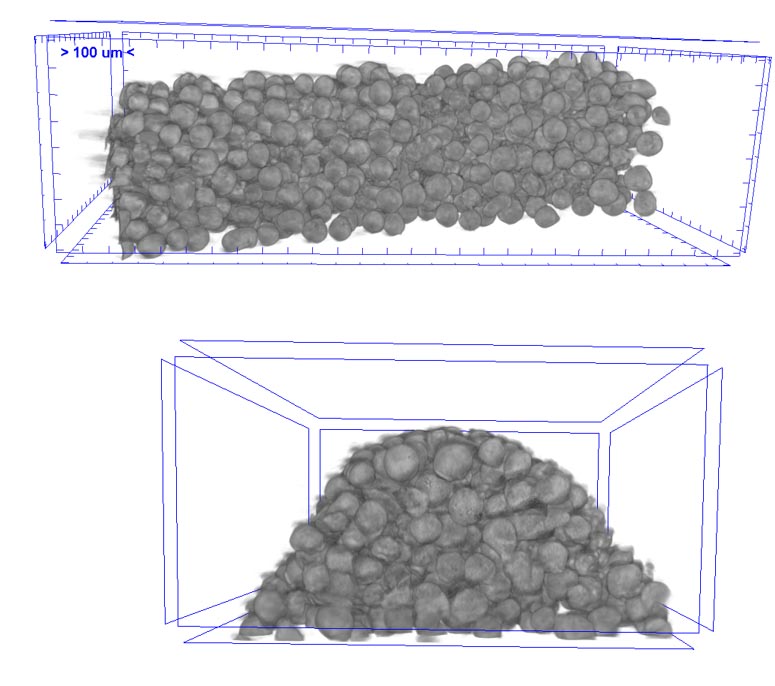

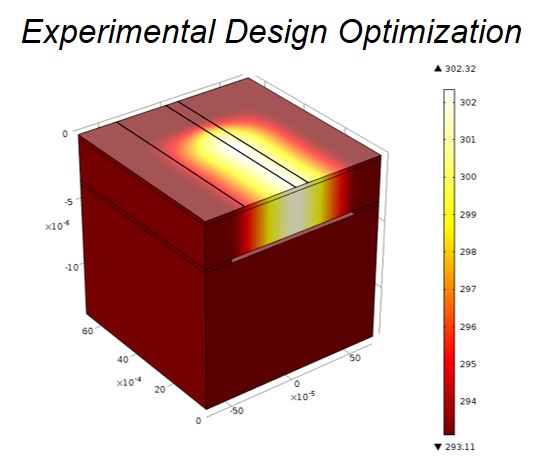

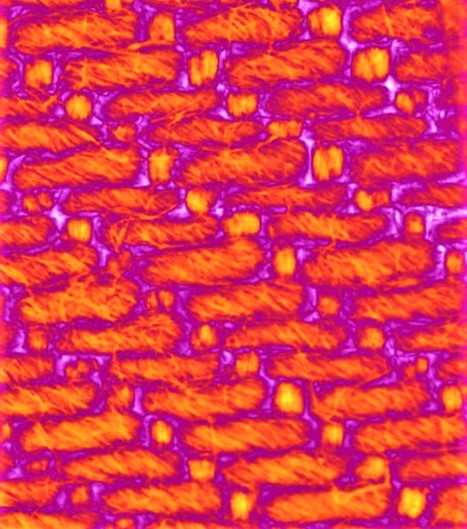

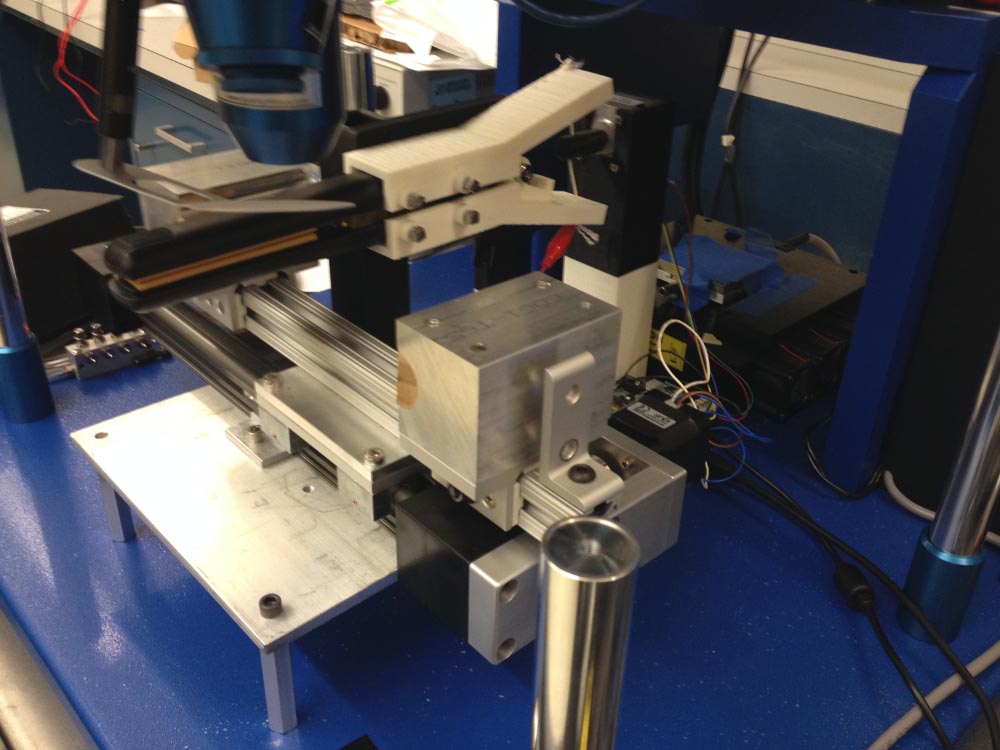

XRCT reconstruction of particle distribution in a mock TIM consisting of ~100 micron diameter copper particles in a UV curable epoxyThermal management of electronics is one of the biggest engineering challenges of this decade, as billions of transistors are put in each microprocessor and the increasing density leads to increased temperatures. TIMs, particularly high thermal conductivity particle-filled polymer composites, are conformable materials that aid in efficient heat conduction from the microprocessor chip to the heat sink through numerous interfaces present in an electronics package. This project is focused on advancing the fundamental understanding of microstructural changes in the TIM, caused by its application process, and its impact on thermal conduction in the material, using validated models. Traditionally, TIM application process, namely dispensing and squeezing, is empirically optimized by investigating a select few dispense patterns (i.e., initial state) and their squeezing, and thermal characterization. The project outcomes will enable a parametric optimization of the material application procedure and eliminates tedious experimentation. The investigation follows a combined state-of-the-art experimental and modeling approach, for the purpose of validating the microstructure and thermal conduction models. Three-dimensional X-ray micro-computed tomography (XRCT) imaging is used to reveal the TIM microstructures in the dispensed and squeezed states, which will help in understanding of the particle rearrangements in the material. These are compared with discrete element method (DEM) simulations of the squeezing process for validation. Infrared (IR) microscopy-based thermal property characterization will be similarly used to validate on-going efforts in TIM thermal conduction modeling.

Students: Rajath Kantharaj

Alumni: Jackson Santana (Fall 2018-Spring 2019)

Sponsor: Cooling Technologies Research Center (joint project with Prof. Aaron Morris and Prof. Carl Wassgren)

Selected Related Publications:

- Effect of Particle Arrangement on the Effective Thermal Conductivity of Polymer Composites 2019 Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM), Las Vegas, NV, 2019. DOI:10.1109/ITHERM.2019.8757409

- Thermal Conduction in Graphite Flake-Epoxy Composites Using Infrared Microscopy: Local and Effective Thermal Characteristics 2017 Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM), Orlando, FL, 2017 DOI:10.1109/ITHERM.2017.8023960

- Granular Jamming and Thermal Modeling in Faceted Particle Packings 33rd ITCC International Thermal Conductivity Conference, Logan, UT, 2017

- Coupled Rheology and Thermal Transport in Granular Materials ASME 2016 IMECE, Phoenix, AZ, 2016.

Battery Thermal Management

Battery Thermal Management

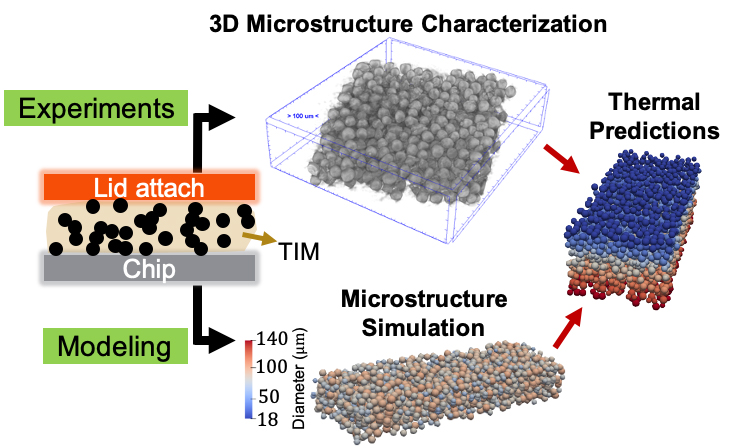

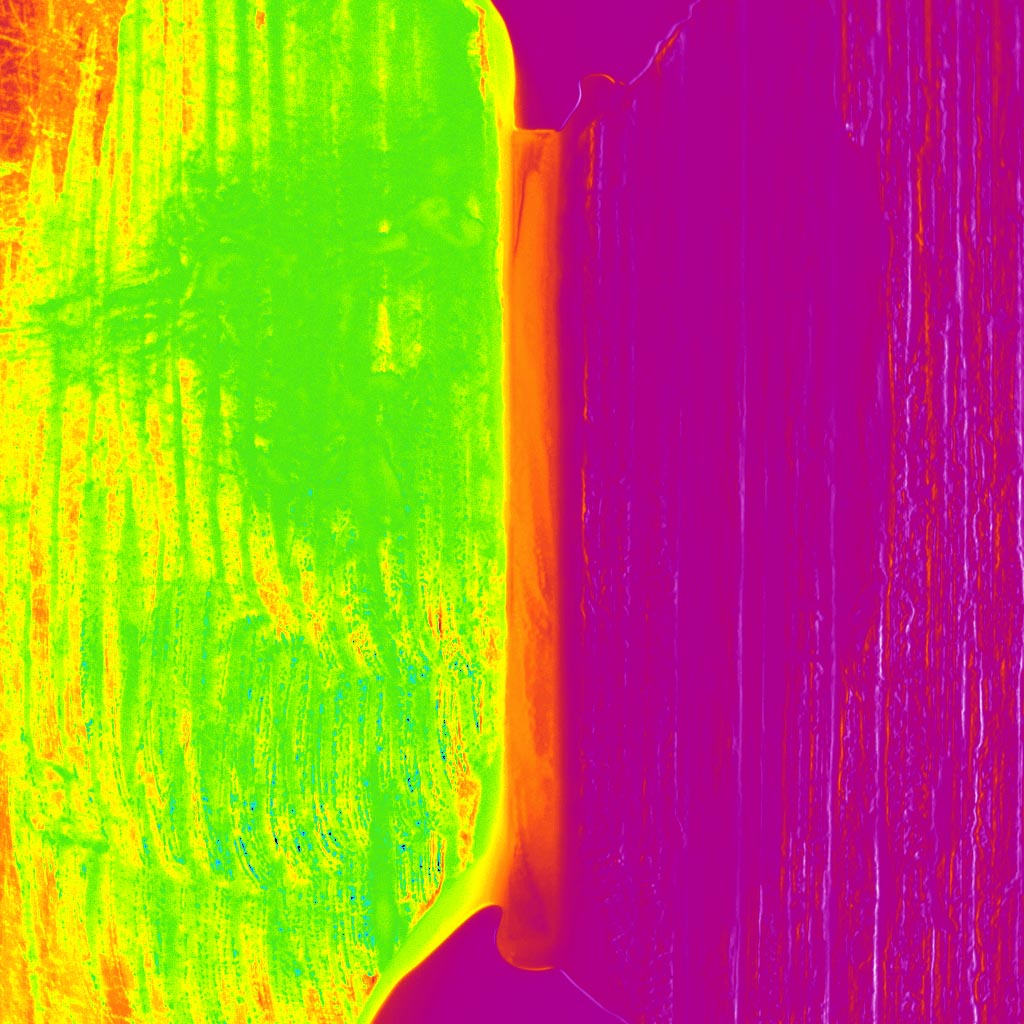

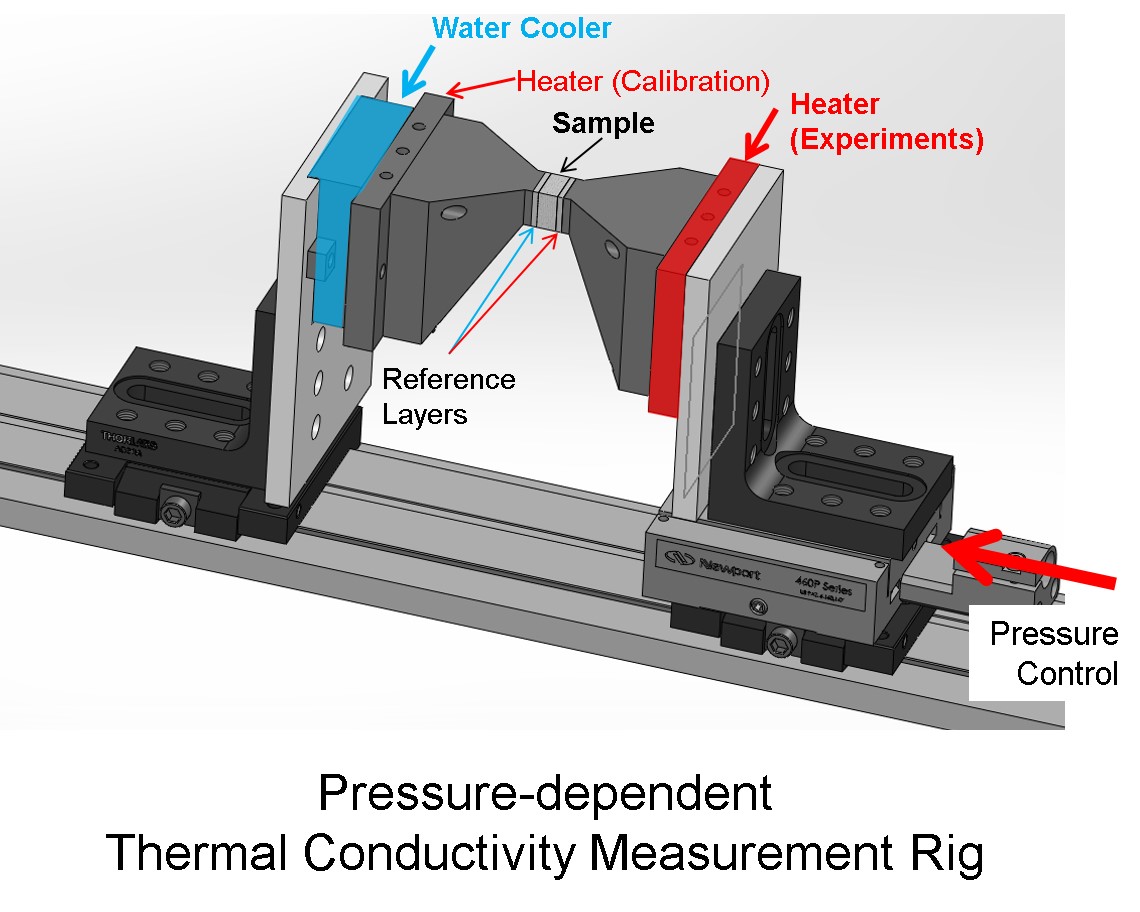

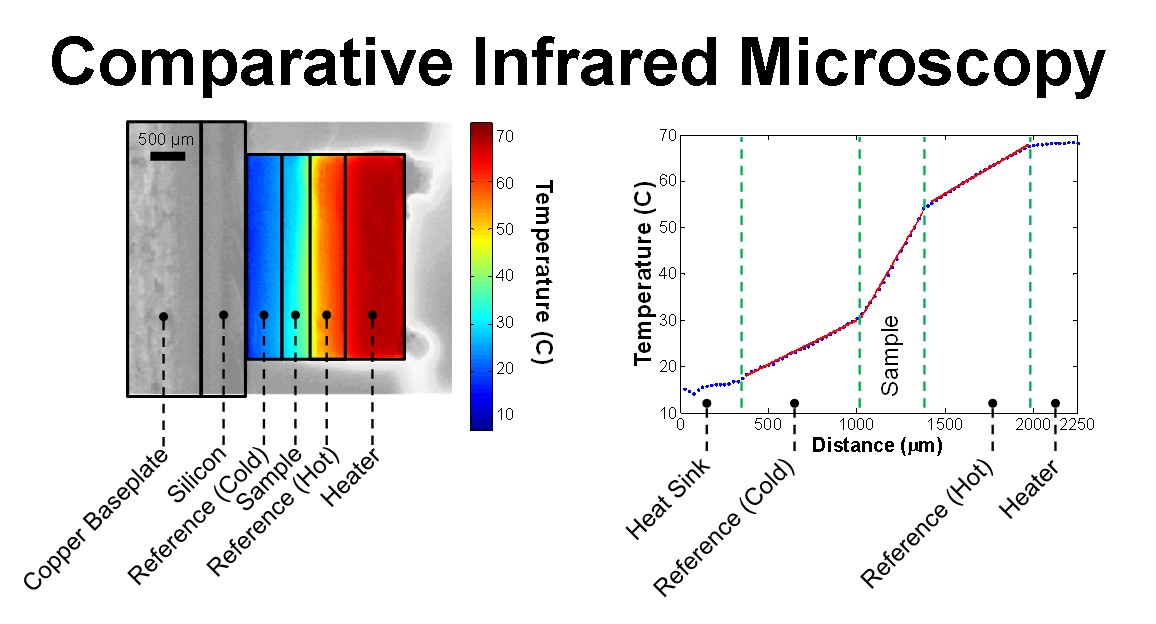

Cross-plane thermal transport generally limits heat removal from the multilayer stacks that form prismatic and spiral-wound batteries. The heat must conduct to the case through many layers of the anode-separator-cathode structure. Few measurements of thermal conductivity exist, even for common cathode and anode materials, and the in situ interface resistance is virtually unknown. We are currently measuring the cross-plane thermal conductivity and interface resistances within battery cells using a miniaturized version of the conventional reference bar method integrated with high-resolution infrared thermography to quantify thermal properties in realistic battery geometries and conditions.

Students: Rajath Kantharaj, Swagata Kalve

Alumni: Aalok Gaitonde (MS 2016), Amulya Nimmagadda (MS 2017), Bhagyashree Ganore (MS 2017), Swagata Kalve (MS 2017), Yexin Sun (MS 2019)

Sponsor: 2016 - NASA \ AMA

Selected Related Publications:

- Gaitonde, Nimmagadda, and Marconnet, "Measurement of Interfacial Thermal Conductance in Lithium Ion Batteries", Journal of Power Sources, vol. 343, 2017. doi:10.1016/j.jpowsour.2017.01.019 [link to full text]

- Gaitonde, Nimmagadda, and Marconnet, "Experimental Characterization of Thermal Conductance across the Separator-Shell Interface in Dry Cylindrical Lithium Ion Batteries", ITHERM 2017, Orlando, FL. [Link]

Phase Change Materials for Thermal Management

Phase Change Materials for Thermal Management

Develop a thermal management solution based on phase change materials (PCMs) to be utilized within or in contact with semiconductor packages in order to store energy generated by the package.

- Longer duration for operation of the package and/or device before the thermal limit of the package/system is reached.

- Enable locally high removal rates at hot spot locations (phase change + improved thermal conduction), allowing convenient integration and application to existing device configurations

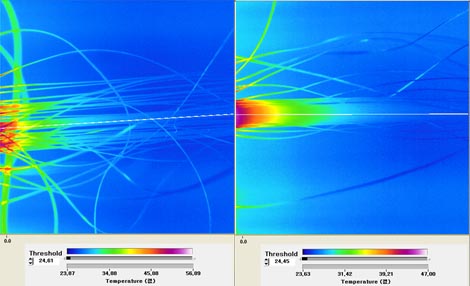

Two-dimensional surface temperature maps of (a-b) the bare processor die and (c-d) the die with an enclosure containing phase change material (PCM) at two time while running a benchmaring app . At each time, the surface temperature of the PCM shown in (c-d) are significantly cooler than those of the bare die. Temperatures measured within the processor show the processor temperature is significantly lower with the PCM thermal management solution. The dashed lines in (a-b) show the outline of the ~1 cm^2 device and the enclosure containing the PCM in (c-d) is oversized compared to the die.

Two-dimensional surface temperature maps of (a-b) the bare processor die and (c-d) the die with an enclosure containing phase change material (PCM) at two time while running a benchmaring app . At each time, the surface temperature of the PCM shown in (c-d) are significantly cooler than those of the bare die. Temperatures measured within the processor show the processor temperature is significantly lower with the PCM thermal management solution. The dashed lines in (a-b) show the outline of the ~1 cm^2 device and the enclosure containing the PCM in (c-d) is oversized compared to the die.

Students: Meghavin Bhatasana (2020 - present)

Alumni: Yash Ganatra (MS 2016), Zhenhuan Xu (MS 2016), Claire Lang (Undergraduate Assistant 2014), Michael Woodworth (Undergraduate Assistant 2015), Adrian Ruiz (Undergraduate Assistant 2016), Prahlad Kulkarni (MS 2018), Prachi Kale (MS independent study 2017-2018), Collier Miers (PhD 2019)

Sponsor: Cooling Technologies Research Center

Selected Related Publications

- "Passive Thermal Management Using Phase Change Materials: Experimental Evaluation of Thermal Resistances" at InterPACK 2015.

- "Investigation of Aluminum Foams and Graphite Fillers for Improving the Thermal Conductivity of Paraffin Wax-based Phase Change Materials" at ITHERM 2017

- Yash Ganatra's MS Thesis: Passive thermal management using phase change materials

Fundamentals of Nanoscale Thermal Transport

Phonon Transport in Nanostructures

Phonon Transport in Nanostructures

- Fundamental Physics: Separate the effects of coherent and incoherent phonon scattering in nanostructures, including periodically porous films.

- Experimental: Develop fabrication technique and metrology platform to conclusively determine the impact of nanostructures on the order of the phonon mean free path.

- Theory and Modeling: Develop models to understand and predict the properties for arbitrary materials.

Target applications: Thermoelectrics, thermal insulation, thermal diodes and rectifiers

Compact Phonon Transport Model

![]()

Students: Krishna Korlam (2019 - present)

Alumni: Dr. Yuqiang Zeng (Graduated 08/2018)

Selected Related Publications

- Reevaluating the suppression function for phonon transport in nanostructures by Monte Carlo techniques, Journal of Applied Physics, 125, 034301, 2019. DOI: 10.1063/1.5048626

- Thesis: Zeng, Tuning Thermal Transport in Thin Films, 2018.

- A Direct Differential Method for Measuring Thermal Conductivity of Thin Films, Reveiw of Scientific Instruments, 88, 044901, 2017. DOI: 10.1063/1.4979163

- Phonon Thermal Conduction in Periodically Porous Silicon Nanobeams, ITHERM 2014, Orlando, FL, 2014.

- Simulation and Optimization of an In-plane Thermal Conductivity Measurement Structure for Silicon Nanostructures, International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES), West Lafayette, IN, 2014.

- From the Casimir Limit to Phononic Crystals: Twenty Years of Phonon Transport Studies using Silicon-on-Insulator Technology, Journal of Heat Transfer, Vol. 135, No. 6, 061601, 2013.

- Phonon Conduction in Periodically Porous Silicon Nanobridges, Nanoscale and Microscale Thermophysical Engineering, Vol. 16, No. 4, pp. 199-219, 2012.

Heat Transfer in Natural and Synthetic Fiber Systems

High Conductivity, Flexible Fabrics

High Conductivity, Flexible Fabrics

Low-power, wearable electronic devices require methods of attachment to non-flat surfaces, specifically the human form, as well as thermal management techniques to meet ergonomics-driven temperature constraints. Thermally conductive polymer fabrics can potentially serve as the device substrate while simultaneously providing heat spreading functionality. In this project, an intrinsic high thermal conductivity polymer material is identified, and its thermal properties are characterized in the fiber, yarn and fabric form by developing an infrared microscopy-based experimental measurement technique. The constructed plain-weave polymer fabric prototype is measured to have a high in-plane effective thermal conductivity (~10 W/mK), and a complementary reduced-order thermal model is also developed to predict effective fabric conductivity behavior. The project also includes design of laser-based non-contact techniques to measure in-plane anisotropy of these materials, as well as bend testing methods to assess the mechanical flexibility of the woven fabrics. The major expected outcome of the project is the development of thermomechanical metrology techniques and baseline experimental characterization results for wearable/flexible fabrics constructed from thermally conductive polymers, indicating great potential for their integration in high-performance wearable electronic packages where heat spreading is a crucial consideration.

Students: Aaditya Candadai

Alumni: RadhaKrishna Korlam (PURE 2018), Emily Nadler (Spring 2019 - Spring 2020), Jack Burke (Summer 2019)

Sponsor: Cooling Technologies Research Center (joint project with Prof. Justin Weibel)

Selected Related Publications:

-

Thermal Conductivity of Ultrahigh Molecular Weight Polyethylene: From Fibers to Fabrics, A.A. Candadai, J.A. Weibel, and A.M. Marconnet, ACS Applied Polymer Materials, 2, 2020. DOI:10.1021/acsapm.9b00900

- A Measurement Technique for Thermal Conductivity Characterization of Ultra-High Molecular Weight Polyethylene Yarns Using High-Resolution Infrared Microscopy 2019 Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM), Las Vegas, NV, 2019. DOI:10.1109/ITHERM.2019.8757385

The Beauty of Mechanical Engineering

The Beauty of Mechanical Engineering

Professor Tahira Reid and the Research in Engineering and Interdisciplinary Design (REID) Lab use interdisciplinary methods to investigate challenging problems that impact: (1) End-users of products and systems and (2) Designers of products and systems. Her projects on Socially and Culturally Relevant Engineering Design (SaCRED) specifically seek to understand social constructs of individuals and groups and how these elements may inform design processes or the actual design of a system.

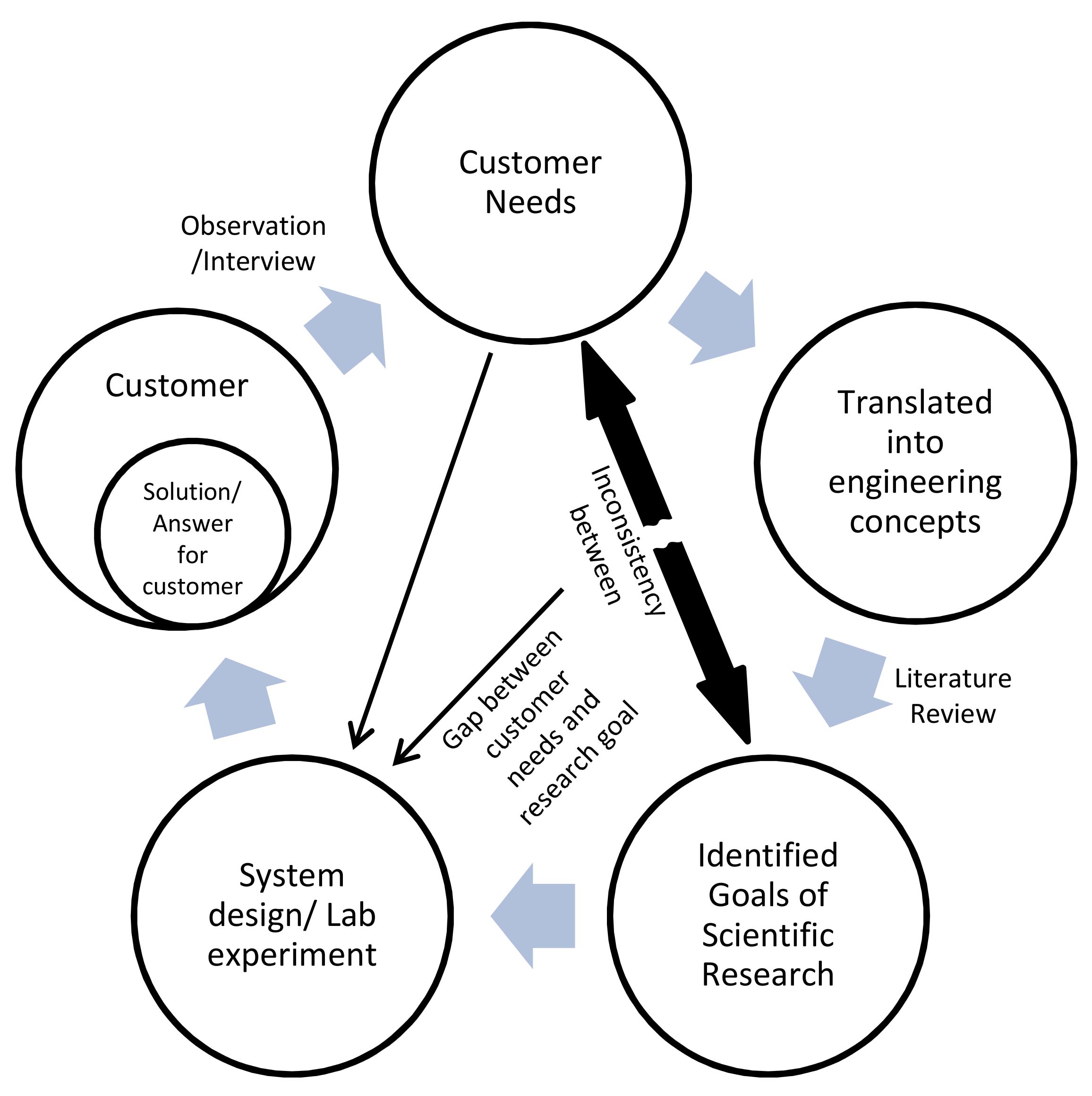

Although the hair care industry is a multi-billion dollar industry, there still remains a dearth in the available technologies and research methods to answer one simple question: What temperature and frequency of use will lead to permanent structural damage (i.e. heat damage) to curly hair? The MTEC lab and the REID lab are developing an interdisciplinary approach to integrating customer needs, design methodology, and thermal sciences for application to the hair care industry. We are developing a predictive model and an experimental test-bed for collecting data on thermal transport and heat induced damage in hair.

Flow diagram of addressing the gap in the ecological consistency between scientific research and customer needs

Prototype of the automated flat ironing device integrated with the infrared microscope.

Alumni: Jaesik Hahn (REID/MTEC Lab), Tikyna Dandridge (REID Lab), Priya Seshadri (REID Lab)

Selected Related Publications:

-

Thesis: Hahn, How Heat Affects Human Hair: Thermal Characterization and Predictive Modeling of Flat Ironing Results, 2018.

-

Integrating Design Methodology, Thermal Sciences, and Customer Needs to Address Challenges in the Hair Care Industry, ASME 2015 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Boston, MA, 2015.

Thermofluids Interactions

Heat Transfer in Particle-Laden Suspensions

Heat Transfer in Particle-Laden Suspensions

Students: Pranay Nagrain (2019 - present)

Students: Pranay Nagrain (2019 - present)

Collaborator: Prof. Ivan Christov

Two-Phase Fluids & Porous Media

Two-Phase Fluids & Porous Media

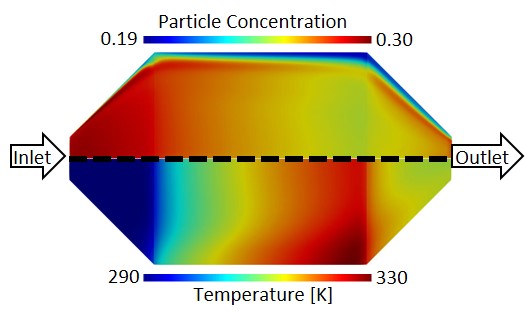

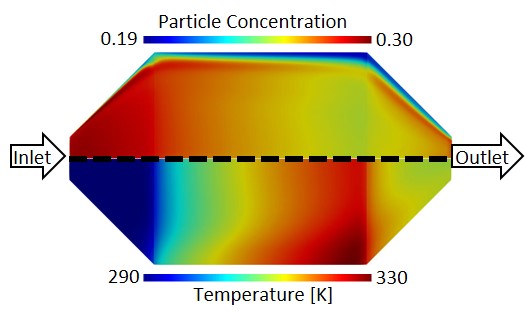

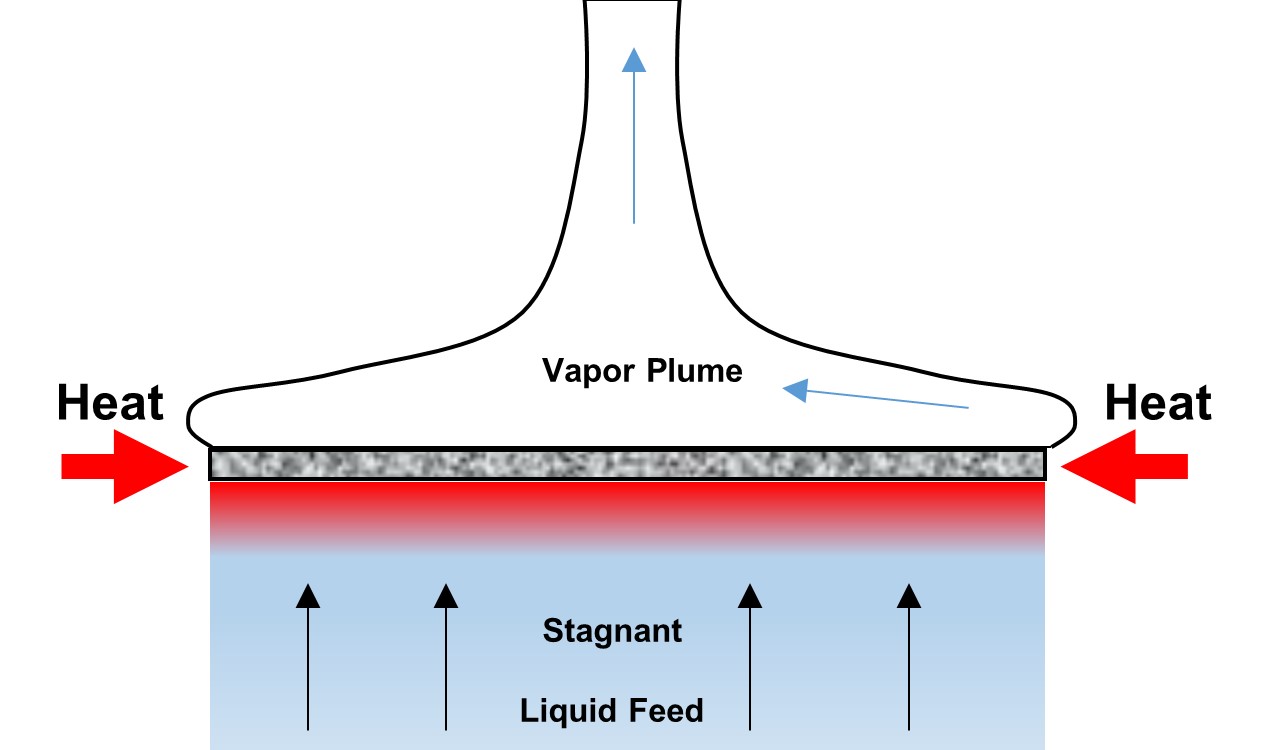

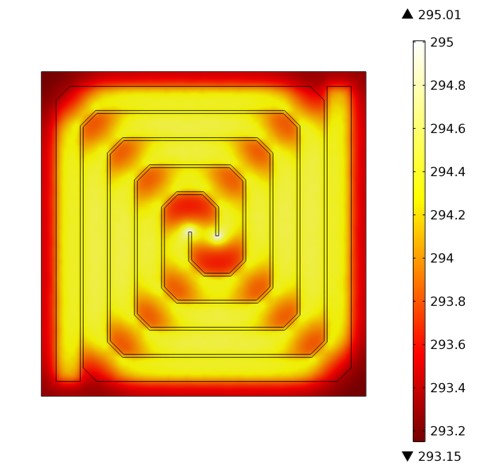

Membrane Distillation (MD) has emerged lately as promising technology for desalination. As oppose to alternative technologies, MD can operate at low temperature and pressure while maintaining 100% rejection rate. Additionally, MD is less sensitive to feed concentration which increase distilled water yield of desalination process. Consequently, MD has been proposed to utilize waste low grade heat or renewable solar energy for desalination processes. However, one major drawback of MD is the high energy consumption despite the continuous effort to optimize the processes through various configurations. We are presently evaluating a novel configuration to reduce energy consumption of MD while maintaining state of art mass flux rate through membranes. Localizing heat generation at the liquid-membrane interface reduces ambient exposure of heated mass resulting in reduction of ambient thermal losses. Additionally, operating on stagnant feed eliminates energy required for circulating fluid.

Students: Albraa Alsaati (MS Thesis 2018, PHD in progress), Luis Delgado

Selected Related Publications:

- Alsaati and Marconnet, Energy Efficient Membrane Distillation through Localized Heating, Desalination, vol. 442, pp. 99-107, 2018. DOI: 10.1016/j.desal.2018.05.009

- M.S. Thesis: Alsaati, Heat and Mass Transfer Analysis for Membrane Distillation, 2018.

Multi-Physics Metrology Design

IR Thermal Metrology

IR Thermal Metrology

With the recent advances in nanoscale and microscale devices and materials, improved metrology techniques are needed to provide insight thermal properties and device performance. High resolution infrared (IR) microscopy allows non-contact, high-resolution (~1.7 μm/pixel), two-dimensional, transient temperature mapping for applications ranging from identifying hot spots in novel devices to improved methods for Seebeck coefficient and thermal conductivity for new materials. We are developing methods to take advantage of the temperature mapping capabilities and allow measurement of microstructure materials.

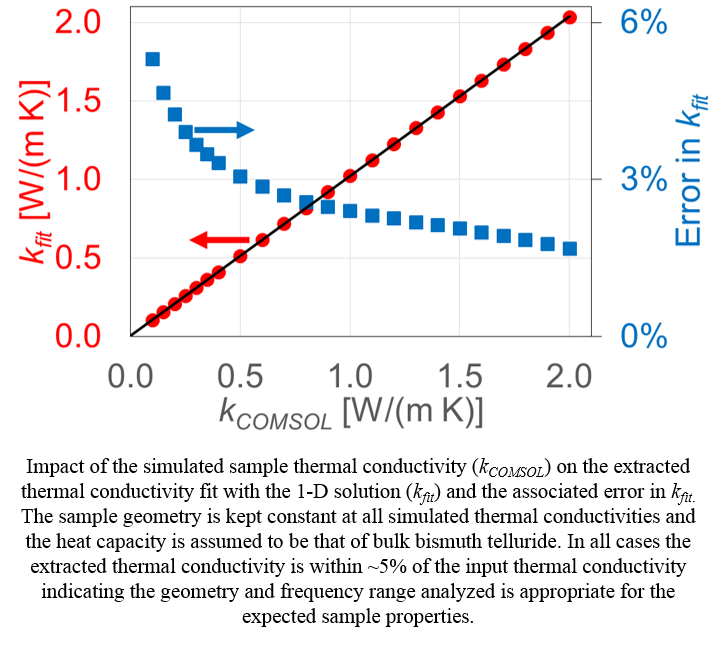

- For example, measuring the thermal properties of thin films is often challenging due to the high surface to volume ratio and unintended heat loss pathways. We developed an improved technique for measuring the thermal diffusivity of thin films using a modified Ångström method. As opposed to conventional techniques, using the IR microscope allows non-contact temperature sensing eliminating heat loss pathways that would be present if thermocouples were used.

- A miniaturized 1-D reference bar method allows characterization of thermal conductivity and has proven useful for characterization of a range of materials from carbon aerogels to liquid metals.

- Finally, combining the temperature mapping capabilities of the IR microscope with electrical measurements allows characterization of thermoelectric properties. The precise measurement of the spatial temperature gradients yields high accuracy characterization of Seebeck coefficient ensuring that the temperature is known at the locations of the voltage measurements.

Students: Rajath Kantharaj, Aaditya Candadai

Alumni: Aalok Gaitonde (MS 2016), Yash Ganatra (MS 2016)

Selected Related Publications

- Reactive Metal Bonding of Carbon Nanotube Arrays for Thermal Interface Applications, IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 4, No. 12, 2014. doi:10.1109/TCPMT.2014.2369371

- Effects of heat treatment on the thermal properties of highly nanoporous graphene aerogels using the infrared microscopy technique, International Journal of Heat and Mass Transfer, vol. 76, p. 122-127, 2014.

- Thermal and electrical properties of graphene/carbon nanotube aerogels, Colloids and Surfaces A, vol. 445, pp. 48-53, 2014.

- Thermal Cycling, Mechanical Degradation, and the Effective Figure of Merit of a Thermoelectric Module, Journal of Electronic Materials, Vol. 42, No. 3, pp. 372-381, 2013.

- Thermal Conduction in Aligned Carbon Nanotube–Polymer Nanocomposites with High Packing Density, ACS Nano, vol. 5, pp. 4818-4825, 2011.

Thermal & Thermoelectric Properties of Nanostructures

Thermal & Thermoelectric Properties of Nanostructures

Goals:

-

Develop new nanostructured porous materials to achieve unique combinations of materials properties not available in bulk materials.

-

Design new metrology techniques for characterizing multiple types of properties simultaneously (including thermal, electric, and thermoelectric).

Target Applications:

-

Lightweight & thermally conductive metallic structures for heat dissipation, surfaces for enhanced boiling, etc.

-

Enhanced ZT for TE materials [Low k and high power factor (S2*σ)]

Metrology Design:

-

Develop a novel characterization structure for simultaneous measurements of thermal, electric, and thermoelectric properties to improve accuracy and reliability of the measurements.

Materials Development:

-

Engineer materials with unique combinations of properties through phonon engineering and physics-based nanostructure design including

-

Lightweight, flexible, low-cost material with high ZT (thermoelectric figure of merit) resulting from low thermal conductivity and a high power factor

-

Lightweight & thermally conductive structures

-

Students: Collier Miers, Albraa Alsaati

Selected Related Publications:

-

Thermal Transport in Electrically Conducting Polymer Microdots, MRS Fall Meeting, Boston, MA, 2014

-

Integrated Device for the Simultaneous Characterization of Thermal and Thermoelectric Properties, MRS Fall Meeting, Boston, MA, 2014.

-

Simulation and Analysis of an Integrated Device to Simultaneously Characterize Thermal and Thermoelectric Properties, International Thermal Conductivity Conference (ITCC) and the International Thermal Expansion Symposium (ITES), West Lafayette, IN, 2014.

Thermal Properties of Soft Nanomaterials

Thermal Properties of Soft Nanomaterials

- Develop a low cost soft materials that respond to external stimuli such as temperature, pH, electric field, or illumination.

- In parallel, we seek to develop a low cost, reliable, accurate method of measuring the thermal conductivity and thermal diffusivity of soft materials.

Alumni: Jiahong Fu, Qianru (Sally) Jia

Selected Publications:

- Thermal Properties of Soft Nanomaterials: Thermal Measurement Design, Yu Han, SURF Project Report, 2014.

- Thermal Properties of Soft Nanomaterials: Materials Synthesis and Fabrication, Meng Pan, SURF Project Report, 2014.