Elliott B. Slamovich

Research Interests

Hydrothermal Processing of Ceramic Powders and Thin Films Supported by the National Science Foundation (DMR-9623744)

Ceramic Powders

|

|

Hydrothermal processing enables the synthesis of many crystalline ceramic materials without a calcination step at temperatures of 200oC and lower. In contrast to solid-state powder fabrication routes, nucleation and growth of crystalline powders during hydrothermal processing takes place via dissolution and precipitation of reactants in an aqueous medium. While temperature is the key to particle size control during calcination, the hydrothermal processing parameters that influence dissolution/precipitation behavior and subsequent particle coarsening are not as readily defined. The research effort described below examines the effects of hydrothermal processing parameters on the chemical composition and morphology of functional ceramic powders like BaTiO3, SrTiO3, (a,Sr)TiO3 and PbTiO3.

Ceramic Thin Films

|

|

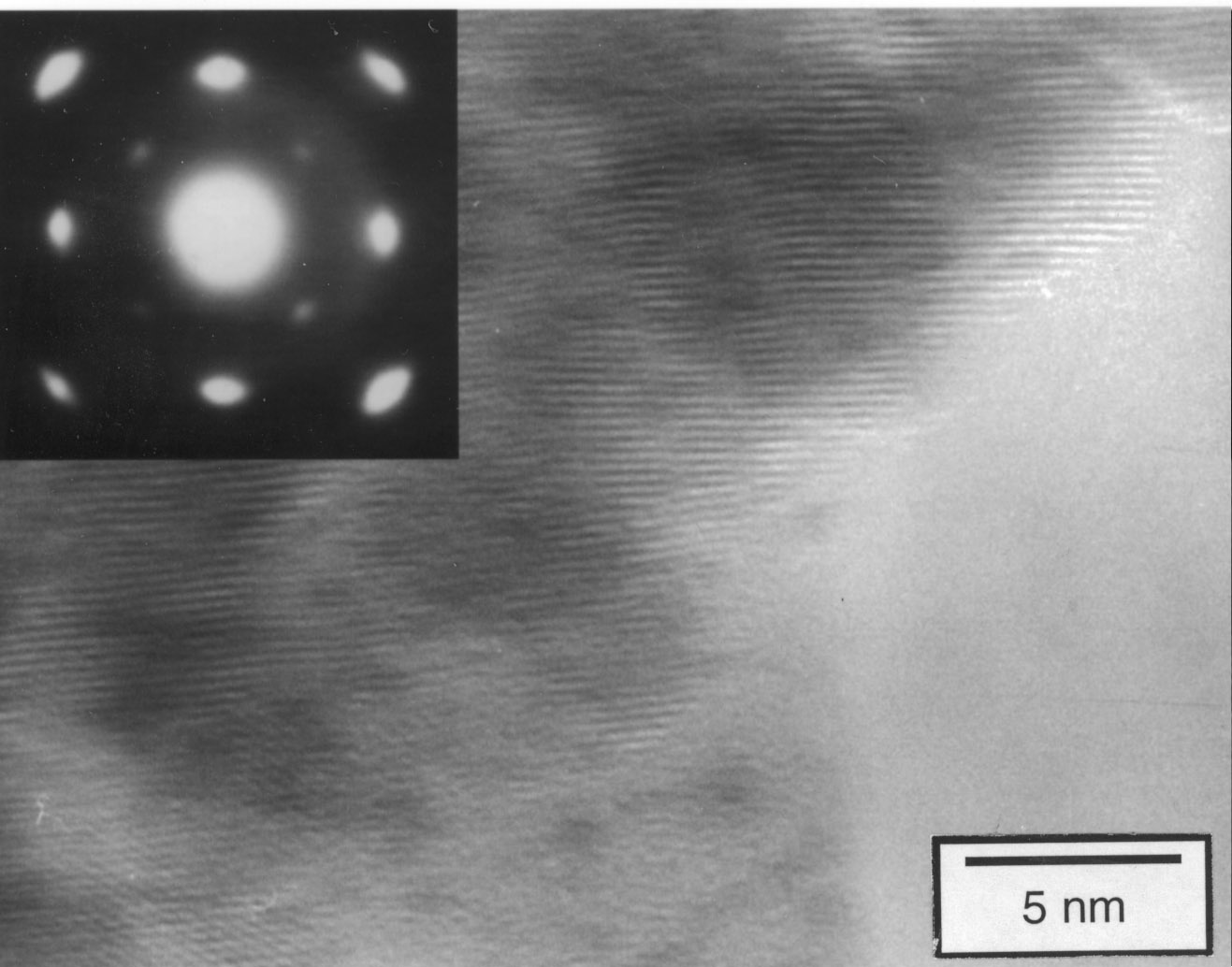

The motivation for investigations into the hydrothermal processing of ceramic thin films comes from the electronics industry. The performance of microelectronic devices is often dictated by materials constraints. For example, increases in the capacity of dynamic random access memory cells (DRAM) necessitates increasing the stored charge density on the device. While recent generations of DRAM have relied on more efficient capacitor geometries, future generations of DRAM will require improvements in the charge density of the capacitor materials themselves. Functional ceramics including BaTiO3 and (Ba,Sr)TiO3 are strong candidates for this role. However, even relatively low temperature sol-gel routes to ceramic thin films require processing temperatures too high (> 600oC) to be compatible with microelectronics fabrication processes. Hydrothermal processing, involving the formation of materials in an aqueous medium, enables the processing of ceramics like BaTiO3 and (Ba,Sr)TiO3 below 200oC.

Representative Publications

- Zhiyuan Ye*, Elliott B. Slamovich, and Alexander H. King, “Size-Driven Domain Flipping in Hydrothermally Derived Lead Titanate Nanoparticles,” J. Mater. Res., 20 [3] 558-562 (2005).

- Michiko Sato*, Elliott B. Slamovich, and Thomas J. Webster, “Enhanced Osteoblast Adhesion on Hydrothermally-Treated Hydroxyapatite/Titania/Poly(Lacide-Co-Glycolide) Sol-Gel Titanium Coatings,” Biomaterials, 26 1349-1357 (2005).

- Jacob L. Jones*, Elliott B. Slamovich and Keith J. Bowman, “Domain Texture Distributions in Tetragonal Lead Zirconate Titanate by X-ray and Neutron Diffraction,” J. Appl. Phys., 97 034113, 1-6 (2005).

- Mark A. McCormick* and Elliott B. Slamovich, “Microstructure Development and Dielectric Properties of Hydrothermal BaTiO3 Thin Films,” J. Eur. Ceram. Soc., 23 2143-52 (2003).

- Huiwen Xu*, Keith J. Bowman and Elliott B. Slamovich, “Hydrothermal Processing of Bismuth Titanate,” J. Am. Ceram. Soc., 86 [10] 1815-17 (2003).

- Mark A. McCormick*, Ryan K. Roeder*, and Elliott B. Slamovich, "Processing Effects on the Composition and Dielectric Properties of Hydrothermally Derived BaxSr(1-X)TiO3 Thin-Films," J. Mater. Res., 16 [4] 1200-1209 (2001).