M. A. Dayananda's Areas of Interest

My diffusion research program in multicomponent systems includes both theoretical and experimental studies of intrinsic diffusion and interdiffusion in metallic alloys, intermetallic phases and silicides, investigations of diffusion structures and diffusion paths in multiphase systems for interface stability and microstructural evolution, and analysis and development of zero-flux planes and flux reversals for kinetic and thermodynamic interactions among the diffusing species.

Experimental studies have been carried out in several Cu-base, Ni-base and Fe-base ternary alloys, Fe-Ni aluminides, Ni-base high temperature alloys, MCrAlY coatings, U-Pu-Zr fuels, and stainless steel claddings. Diffusion studies in silicides of Mo, W, Ta, Nb and Re have been carried out for the determination of intrinsic and interdiffusion coefficients and energies of activation for diffusion of the individual components. Diffusion studies in the Fe-Ni-Al system with ordered and disordered phases have identified the development of unusual diffusion paths including double serpentine diffusion paths. Interdiffusion of Al in Mo-Si-Al system has been examined by diffusion Al in columnar grained MoSi2 for the assessment of flux contributions from bulk and grain boundary diffusion. Also, a study of diffusion of silver in tricrystals of Cu is currently under way in order to assess diffusion along triple junctions.

New analytical methods have been developed for the determination of of (n-1)2 interdiffusion coefficients from individual, multicomponent solid-solid diffusion couples over various composition ranges selected along the diffusion path. Concepts of integrated and average effective interdiffusion coefficients for individual components are also utilized to model concentration profiles and diffusion paths in multicomponent, multiphase systems. A user-friendly and free computer code called "MultiDiFlux" has been developed for the analysis of diffusion couples and modeling of multicomponent diffusion.

Some areas of current study are identified below.

Isoactivity Diffusion Couples Assembled with α (fcc) Cu-Ni-Zn Alloys for the Development of Zero-flux Planes (Supported by NSF under under Grant No. DMR-0304777)

The scope of this research includes investigation of multicomponent diffusion in the Cu-Ni-Zn system at 775oC with solid-solid diffusion couples for the development of zero-flux planes, diffusion paths and diffusion structures under controlled boundary conditions defined in terms of thermodynamic activities for the individual components. The main objectives are: 1. To examine and regulate interdiffusion of elements with preferential development of zero-flux planes; 2. to investigate intrinsic and interdiffusion in single phase and multiphase diffusion couples under controlled thermodynamic driving forces for one or two of the components.

Experimental diffusion paths for the diffusion

couples assembled with α Cu-Ni-Zn alloys

and annealed at 775oC for 48 hours. P1 and P2

refer to the compositions of the zero-flux planes

for Ni and Cu, developed for the couples, α2

/α16 and α2 / α7, assembled with

alloys characterized by similar thermodynamic

activity for Ni and Cu, respectively.

Direct Determination of Ternary Interdiffusion Fluxes from individual Couples (Supported by NSF under under Grant No. DMR-0304777)

The main objective of this study is to evaluate ternary interdiffusion coefficients from individual couples over various ranges of composition selected in the diffusion zone. Such evaluations and assessments of interdiffusion coefficients are carried out in selected couples assembled with Cu-Ni-Zn (fcc) alloys characterized by similar thermodynamic activities for Cu. The couples are annealed at 775oC. One pair of couples exhibits intersecting diffusion paths and the other pair shows overlapping path segments. The analysis is based on converting profiles of concentrations to profiles of interdiffusion fluxes and evaluating moments of interdiffusion fluxes for the determination of interdiffusion coefficients over selected composition ranges. For the pair with intersecting diffusion paths, ternary interdiffusion coefficients are determined from the individual couples in the region of their common composition; these coefficients are compared with each other and with those determined by the Boltzmann-Matano analysis. For the pair of couples with overlapping diffusion path segments, interdiffusion coefficients are calculated from each couple over the common path segment and compared. In addition, the interdiffusion coefficients calculated over various composition regions are employed to regenerate the concentration profiles of the individual couples. All calculations are carried out with the aid of a computer program called MultiDiFlux, which has been developed by Dayananda and Ram-Mohan as a free educational and research tool for analysis of multicomponent diffusion.

Diffusion paths for the α2 vs. α7 and the

α10 vs. α13 diffusion couples intersecting

at the common composition of 56 at% Cu, 32 at% Ni, and 12

at% Zn.

Diffusion paths of the α3 vs. α15 and the

α3 vs. α18 diffusion couples with

overlapping diffusion paths.

Interdiffusion in the Multiphase Mo-Rich Mo-Si-B Alloys (with Prof. David Johnson)

Alloys in the Mo-Si-B system consisting of a bcc-Mo solid solution and the intermetallic phases Mo3Si and Mo5SiB2 (T2) are candidate materials for high temperature structural applications. The presence of the T2 phase in these alloys may improve the oxidation resistance by promoting the formation of a protective glassy scale. During oxidation at 1300oC a two-phase layer consisting of Mo and glass forms between the base alloy and the external glass layer. An understanding of the oxidation resistance over (1000-1300oC) requires an understanding of interdiffusion of Si, B, Mo, and O in the glassy scale as well as in the two-phase intermediate layer. Such studies are being carried out by analyzing concentration profiles in the various layers developed after oxidation and evaluating average effective interdiffusion coefficients for the individual components on the basis of multicomponent diffusion phenomenology.

|

(Mo+Glass) Two-phase Layer between the Metal and Glass after Oxidation of Alloy MSB-31 at 1300oC for 48hr. |

Enhanced Diffusion at Triple Junctions (with Alexander H. King)

(Supported by US Department of Energy under Contract Number DE-FG01-01ER45940).

At low temperatures, diffusion through triple junctions has been hypothesized to be faster than either grain boundary diffusion or bulk diffusion. Diffusion experiments are being conducted in the copper-nickel system with diffusion couples assembled with tri-crystals of copper, grown using vertical Bridgman technique, with well-prepared polycrystalline nickel specimens. The diffusion couples are annealed for various times at 973K. Elemental concentration maps of the grain boundaries and triple junctions are obtained using an electron microprobe; such maps indicate that the depth of nickel penetration along the triple junctions to be 3-4 times greater than that along the grain boundaries. Our experiments have been designed with a view to allowing for comparison with results from atomistic models. (This work is supported by the US Department of Energy, under contract number DE-FG01-01ER45940).

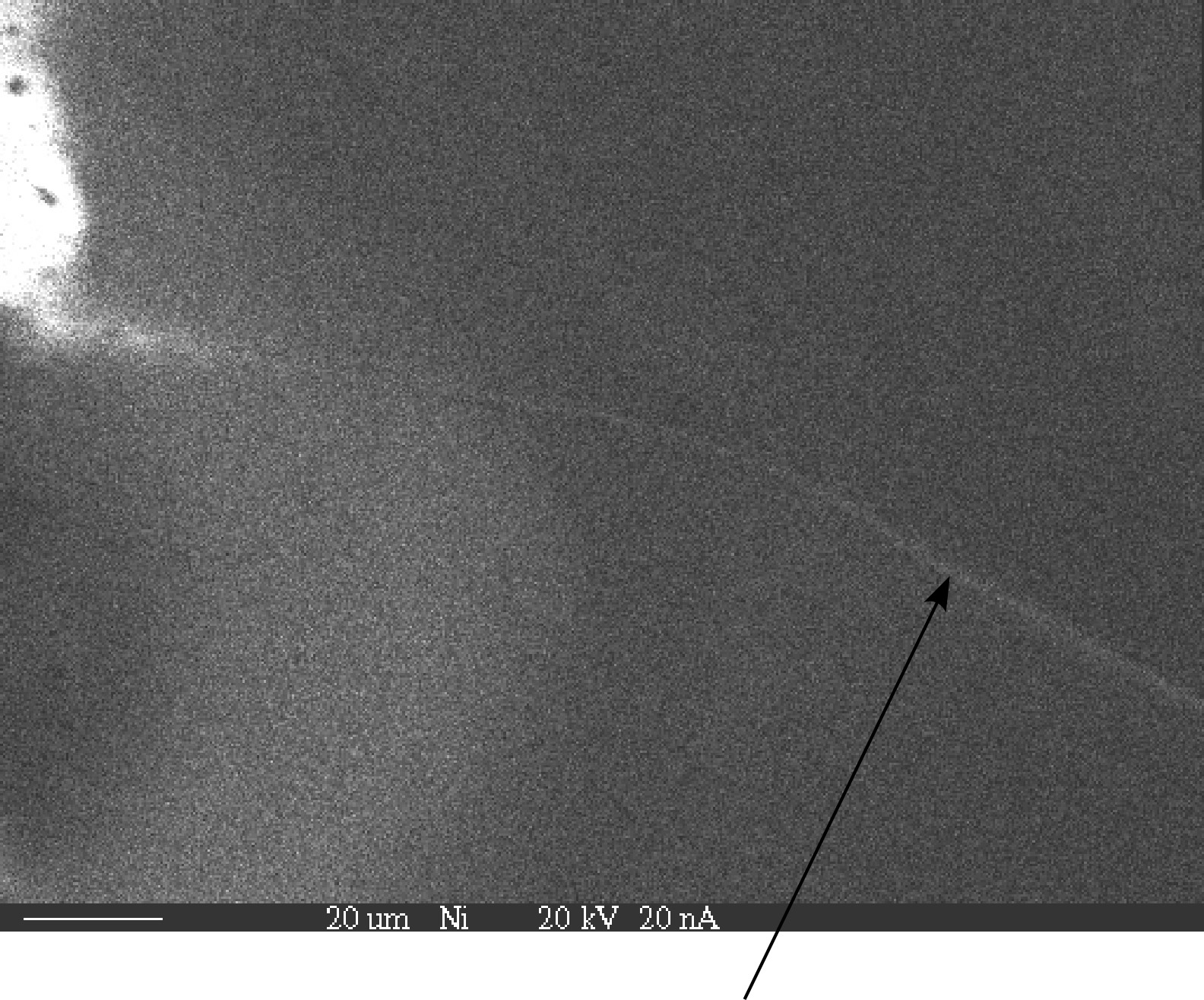

Ni penetration along a grain boundary in a

Cu-tricrystal/Ni couple diffusion-annealed at

700oC for 48 hours.

Recent Publications

- Mysore A. Dayananda and Kevin M. Day: "Analysis of Cu-Ni-Zn Ternary Diffusion Couples Using the MultiDiFlux Program," (Submitted to TMS Letters) 2005.

- K. M. Day, L.R. Ram-Mohan and M.A. Dayananda, "Determination and Assessment of Ternary Interdiffusion Coefficients from Individual Diffusion Couples, submitted for publication to Journal of Phase Equilibria and Diffusion, 2005.

- Y.H. Sohn, A. Puccio, M.A. Dayananda: "Diffusion Structures and Diffusion Paths of Selected Multiphase Couples in the Fe-Ni-Al System," Metall. and Mater. Trans. A, 36A, (in print) 2005.

- R.J. Kremer, M.A. Dayananda and A.H. King: "Low-Temperature Diffusion Data Measured from Historical Artifacts Proceedings of the Materials Research Society, (in Print) 2005.

- "Interdiffusion Structures," J. E. Morral and M. A. Dayananda, Metals Handbook, Vol.9, Metallography and Microstructures ASM, New Edition, 2004, pp.186-191.

- V. Supatarawanich, D.R. Johnson, M.A. Dayananda and C.T. Liu: "Processing and properties of multiphase Mo-Si-B alloys," Materials Science Forum, 426-4 (2003) 4301-4306.

- Y. H. Sohn and M. A. Dayananda: "Diffusion Studies in the b(bcc) and g(fcc) Fe-Ni-Al Alloys at 1000oC," Metall. Mater. Trans. A, 33A, (2002) pp. 3375-92.

- Y. H. Sohn and M. A. Dayananda: "A New Analysis for the Determination of Ternary Interdiffusion Coefficients for Ni-Cr-Al and Fe-Ni-Al Alloys," Elevated Temperature Coatings: Science and Technology IV, Edited by N. B. Dahotre, J. M. Hampikian and J. E. Morral, TMS (2001), pp. 160-170.

- M. A. Dayananda and Y. H. Sohn: "An Analysis for Interdiffusion Coefficients and Thermotransport Coefficients in Isothermal and Nonisothermal Ternary Diffusion Couples," Solid State Phenomena, 72 (2000) pp. 99-104.

- Y. H. Sohn and M. A. Dayananda: "Double Serpentine Diffusion Path in a Ternary Diffusion Couple," Acta Materialia, 48 (2000) pp. 1427-1433.

- M. A. Dayananda: "Diffusion Structures and Diffusion Paths in Ternary Systems-Selected Unusual Observations," Solid State Phenomena, 72 (2000) pp. 123-134.

- M. A. Dayananda and Y. H. Sohn: "A New Analysis for the Determination of Ternary Interdiffusion Coefficients from a Single Diffusion Couple," Metallurgical Transaction A, vol. 30A (1999) pp. 535-543.

- P.C. Tortorici and M.A. Dayananda: "Interdiffusion and Diffusion Structure Development in Selected Refractory Metal Silicides," Materials Science and Engineering, Vol. A261 (1999), pp. 64-77.