Solid Mechanics

While textbooks define Solid Mechanics as the study of the motion, deformation, or fracture of solid materials to external and internal forces -- the breadth of this field is enormous. Solid Mechanics has implications for manufacturing, biomedicine, and much more.

Faculty members in the Solid Mechanics area study fundamentals of continuum mechanics, advance concepts in the field of micromechanics, advance numerical methods such as finite element and phase field approaches, and connect CAD to stress analysis. They work with analytical, numerical and experimental approaches.

In the application of Solid Mechanics faculty members seek to advance the reliability of microelectronic devices, the energy storage in batteries, the behavior of soft and hard tissue, the manufacturing of powder based products, and shape-changing structures.

Faculty in Solid Mechanics

- Renewable Energy Materials (physics-based energy yield predictions, sustainable PV and energy storage materials, recycling)

- Electro-Optical-Thermo-Mechanical Reliability (in-situ and in-operando accelerated stress tests)

- Heterogeneous Integration & Advanced Packaging (sub-10 μm pitch interconnects, low-loss interposers)

- Harsh Environment Electronics Integration (high temperature Pb-free solders and nano-thermal interfaces)

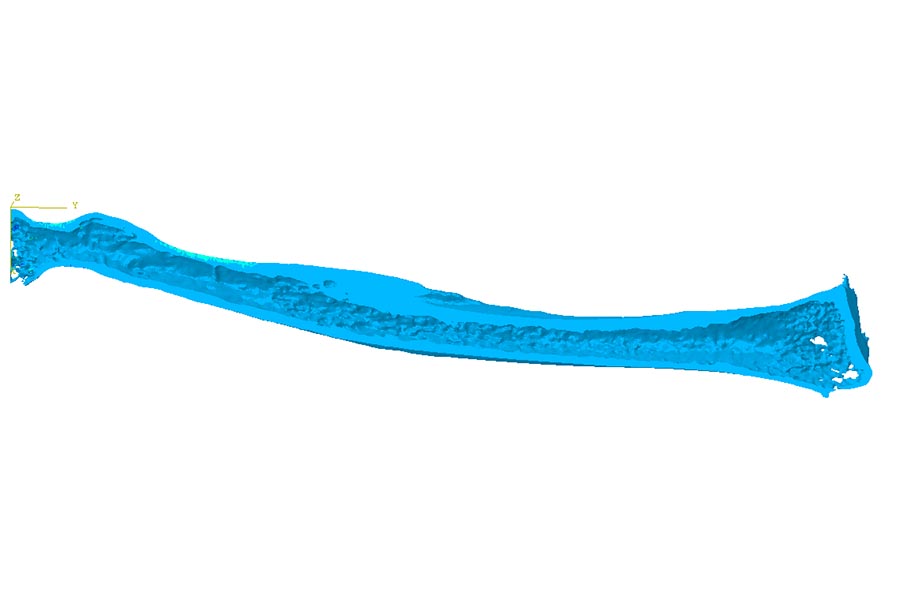

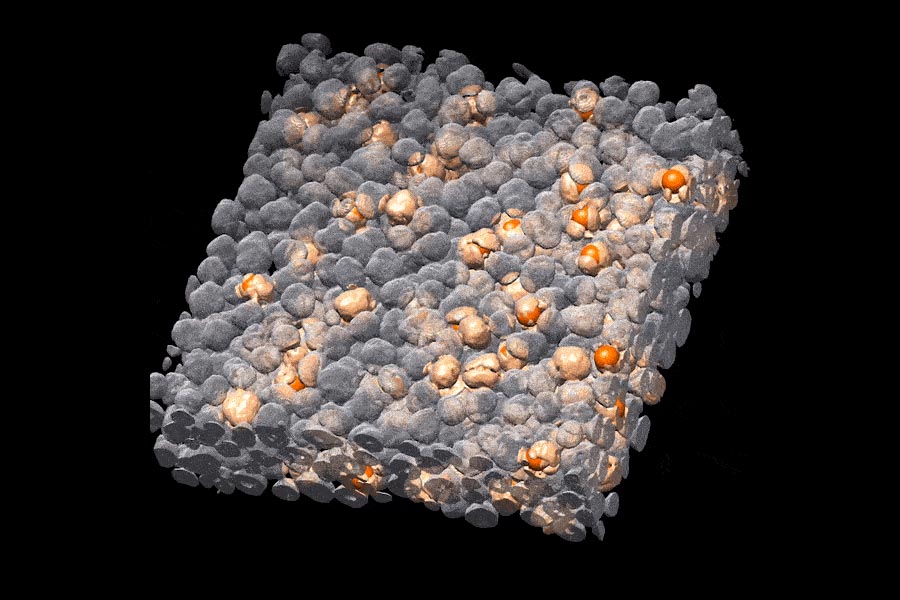

- Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

- Application areas of interest include:

- (i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

- (ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

- (iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

- Thermal stresses, thermal fracture and fatigue of advanced materials, in particular high temperature materials, ceramic coatings.

- Mechanical behavior, design and remodeling of biological tissues, effect of stresses on remodeling, microbiomechanics of cell-extracellular matrix (ECM) interactions, tissue engineering

- Contact mechanics

- Stresses, fatigue and friction of rolling/sliding

- Micro-mechanics of boundary and mixed lubrication regimes

- Spall initiation and propagation

- Surface science and damage

- Dynamics of ball and rolling element bearings and rotating systems

- Friction induced vibration and squeal in dry contacts

- Friction and wear of dry and lubricated contacts

- Virtual tribology

- Dry and lubricated fretting wear

- MEMS for in-situ monitoring of tribological contacts

- Discrete element modeling

- Design

- Computational and experimental solid mechanics focused on fatigue, fracture, and multi-physics phase evolution problems

- Computational techniques including Finite Element Analysis (FEA), Isogeometric Analysis (IGA), geometric modeling, CAD and optimal design

- Heterogeneous Integration and Advanced Electronics Packaging with a focus on thermomechanical behavior, reliability, and electrical-thermal-mechanical co-design

- Discrete element method (DEM) modeling for particulate systems

- -- model development, e.g., fibrous particles, particle breakage, particle shapes

- -- application to manufacturing, e.g., storage and flow, blending, segregation, drying, coating, wet granulation

- Finite element method (FEM) modeling of powder compaction

- -- e.g., roll compaction, tableting, picking and sticking

- Multi-scale modeling (FEM combined with DEM) of powder dynamics

- -- model development and application to hopper flow, blending, and segregation

- Heat Transfer in Advanced Semiconductor Interconnects & Packaging

- Electronic Cooling & Efficient Thermal Packaging Materials

- Thermal/Mechanical Simulation & Characterization

- Materials, Processing & Architecture Development for Semiconductor Packaging

- MEMS Fabrication for Extreme Heat Flux Microfluidic Cooling

- Advanced Semiconductor Nanoscale 3D Interconnections

- Novel Photonics & Quantum Packaging Technologies

- Reliability Modeling & Characterization

- Deformation, stress, plasticity, fracture

- Multiscale modeling, first-principles, molecular dynamics simulations, and finite element modeling

- In-situ experiments

- Mechanics of redox active materials - Li-ion batteries, Na-ion batteries, all-solid-state batteries

- Mechanics of polymeric materials - organic electrochromics, superelastic organic semiconductors