Convergent Manufacturing

Manufacturing has been a central focus of Mechanical Engineering at Purdue, going back to the 1800’s. Today, researchers study every aspect of manufacturing and materials processing, from automotive and aerospace to electronics and medical applications.

By studying the fatigue and fracture of materials, Purdue researchers can pinpoint what needs to be strengthened, and how much. In nanomanufacturing, new breakthroughs enable devices to do things unthinkable just a few years ago. And in the theoretical realm, manufacturing processes and systems are always being refined, allowing companies to build the best products in the best way with the best people.

Faculty in Convergent Manufacturing

Renewable Energy Materials (physics-based energy yield predictions, sustainable PV and energy storage materials, recycling)

Electro-Optical-Thermo-Mechanical Reliability (in-situ and in-operando accelerated stress tests)

Heterogeneous Integration & Advanced Packaging (sub-10 μm pitch interconnects, low-loss interposers)

Harsh Environment Electronics Integration (high temperature Pb-free solders and nano-thermal interfaces)

Modeling and experimental studies on processing

Structure property relationships in polymer films and moldings and polymer/metal/ceramic hybrid systems

Dynamic systems and control

Mechatronics

Digital and functional printing and fabrication

Motion and vibration control and perception

Embedded systems and real-time control

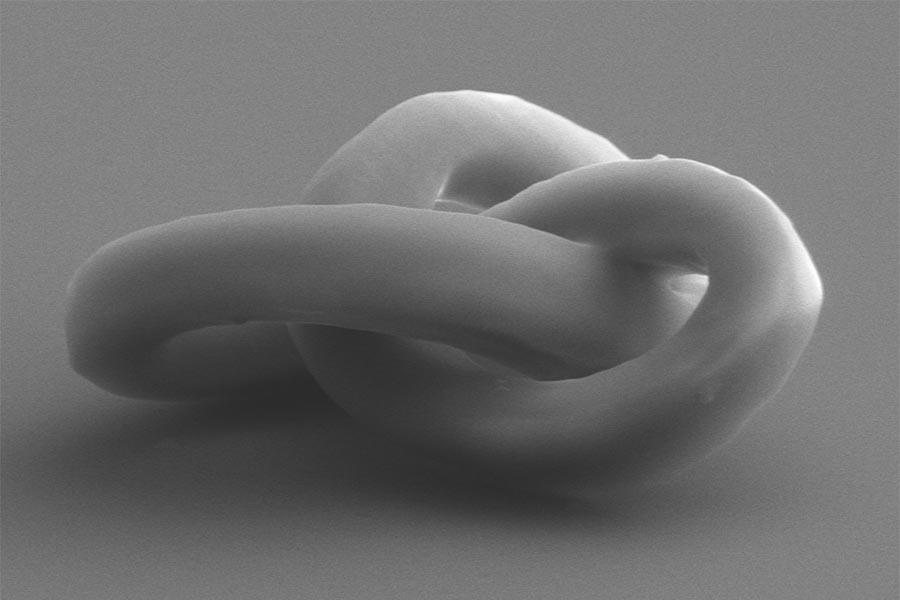

DNA nanotechnology

Advanced materials

Bio-inspired and mechanically adaptive electronics

Multimaterial additive fabrication

Soft actuators (artificial muscles)

Wearable actuators (haptics)

Polymer design and polymer physics

Deformation sensors and transistors

Mechanical systems design

Analysis and simulation

Computer aided engineering

Kinematics

Dynamics

Robotics and automation

Vibrations and nonlinear dynamics

Smart material systems

Non-pneumatic tires

Optimization of mechanical systems

Additive manufacturing

Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

Application areas of interest include:

(i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

(ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

(iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

Biotransport phenomena

Cell-fluid-matrix interaction

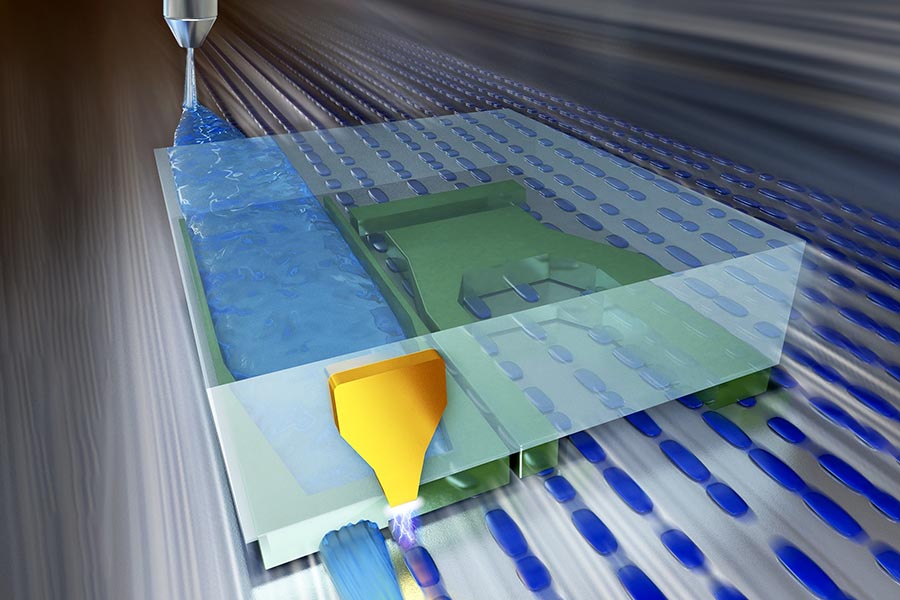

Microfluidics

3D printing of soft materials

Advanced multi-scale manufacturing

Ultrafast laser machining and processing

Fiber optic sensors and environmental monitoring

Spray-based nanoparticle coating and additive manufacturing

Machining of carbon fiber reinforced polymer (CFRP) composites

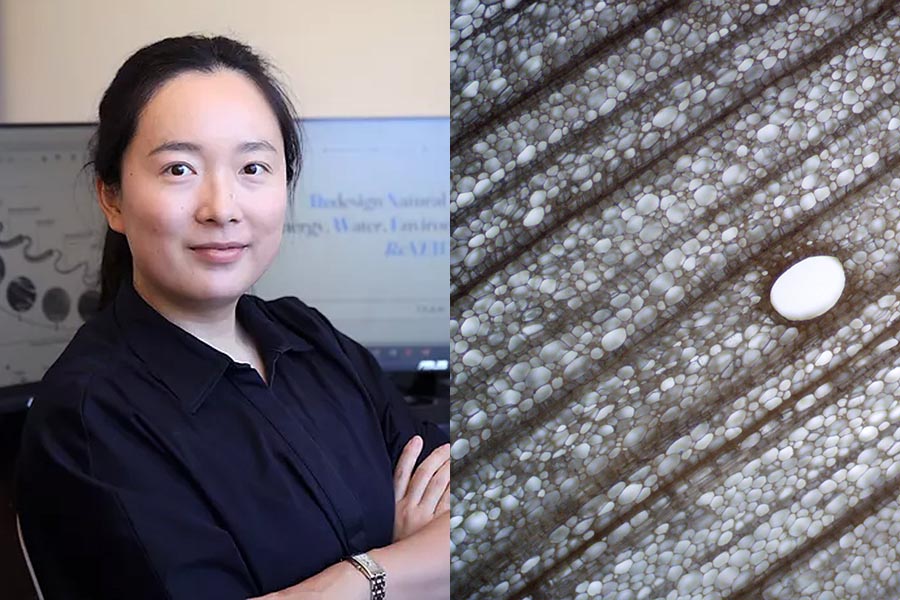

Naturally nanostructured materials

Energy, water, and wearable technology

Manufacturing

Bio-inspired designs

Surface engineering and multifunctional materials

Convergent Manufacturing for Industry 5.0: hybrid manufacturing processes, heterogeneous materials, and bio-inspired designs

Systems integration, productization, and production

Heavy-duty machines: machining, lubrication, and corrosion

Heterogeneous and hierarchical integration (mechanical-electrical-optical and nano-micro-meso-macro)

Precision agricultural and food: cellular agriculture, vertical farming, micro-production, and resilience

Frugal engineering, social innovations, and social equity

Manufacturing in space

Dissimilar material 3D printing

Additive manufacturing of energetic materials

Additive manufacturing of materials for high temperature applications

Quality control in additive manufacturing

Human Skill and Augmentation

Collaborative and Hybridized Intelligence

Deep Learning of Shapes and Computer Vision

Human-Robot-Machine Interactions

Making to Manufacturing (M2M)

Factory of the Future and Robotics

Manufacturing Productivity

Simulations of nanoscale thermal transport

Machine learning, optimization, and high throughput design

Thermal management in electronics, space, and battery applications

Transport phenomena in additive manufacturing

Nanomaterials and devices for sustainable energy

Contact mechanics

Stresses, fatigue and friction of rolling/sliding

Micro-mechanics of boundary and mixed lubrication regimes

Spall initiation and propagation

Surface science and damage

Dynamics of ball and rolling element bearings and rotating systems

Friction induced vibration and squeal in dry contacts

Friction and wear of dry and lubricated contacts

Virtual tribology

Dry and lubricated fretting wear

MEMS for in-situ monitoring of tribological contacts

Discrete element modeling

Design

Laser additive manufacturing

Ultrafast laser matter interaction

Laser welding

Laser assisted machining

Laser shock peening

Multi-physics, multi-scale modeling

Micro-nano manufacturing

Solid mechanics, multiscale and multiphysics modeling.

Design of engineering material systems.

Fracture and fatigue.

Microarchitectured materials.

Biomechanics of soft and hard tissues.

Multi-process/multi-material additive manufacturing

Nondestructive evaluation

Advanced acoustic materials and metamaterials

Ultrasonics

Laser-matter interactions

Laser-induced plasma and laser-plasma interaction

Laser applications in manufacturing, materials processing, and other areas

Heat transfer, particularly nano-scale and ultrafast heat transfer

Ultrafast laser materials processing and diagnostics

Nano-optics and laser-based nano-lithography

Multiscale superfast 3D optical sensing

Biophotonic imaging

Optical metrology

Machine/computer vision

3D video telepresence

3D video processing

Virtual reality

Human computer interaction

Environment friendly design and life cycle engineering

Applications of bio-based materials in manufacturing

Fast and low-cost detection of pathogenic microorganisms

Biomass thermo-chemical upgrading for liquid and gaseous fuel

I want to research in

I want to have an impact in...