Bioenergy

Bioenergy is energy produced from biological materials and/or using biological processes. Forms of bioenergy include electricity, heat, and liquid fuels. Biological feedstocks that are transformed into biofuels come from plants that harvest the energy in sunlight and store it in chemical form by converting CO2 from the air and water into energy-rich molecules with oxygen as a byproduct. The energy-rich molecules come in a variety of forms from sugar (e.g. sugar cane), starch (e.g. corn), oil (e.g. soybeans) and lignocellulose (e.g. wood).

Through a combination of biological and chemical technologies, these solid molecules can be converted to electricity, heat, and/or liquid transportation fuels. Successful commercialization of bioenergy production requires the integration of various technologies to make energy at high efficiency for low cost. LORRE applies bioprocess engineering to integrate fundamental knowledge of chemistry, biology, and biochemistry with practical process technologies to transform renewable plant materials into bioenergy. Success in this work depends upon teamwork across disciplines, as well as teamwork with industrial partners and cooperators at other universities and government laboratories.

Research

The processing of cellulose, hemicellulose, lignin and starch components to biofuels and bioproducts presents unique challenges since the fundamental research must result in biological or biochemical processes that give high yields at low cost. LORRE’s work to achieve this is integrative. It addresses preprocessing of lignocellulosic biomass into a reactive form, carries out development of biocatalysts and chemical catalysts to convert the biomass into sugars, fuels, and bioproducts. This work addresses a suite of bioprocessing and fermentation technologies that are needed to achieve economic feasibility.

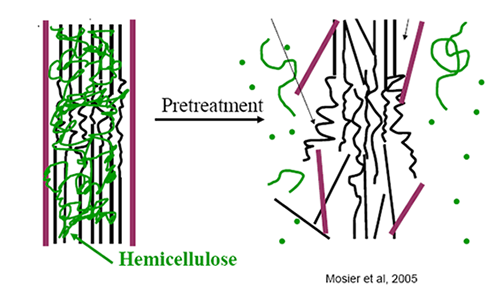

Pretreatments are being developed that make cellulose readily hydrolyzed so that enzymes or other hydrolysis catalysts are more effective. Genetically engineered yeast that ferments both hexose and pentoses to ethanol is being tested in industry. An energy efficient separation technique invented in LORRE and developed with an industry partner is used commercially.

The goal of preprocessing or pretreatment is to alter the micro and nano scale structures of plant biomass in order to make cellulose more susceptible to depolymerization (hydrolysis). Our current work is addressing the engineering of processes for large scale pretreatment, as well as understanding plant cell wall structure to enhance cellulose and hemicellulose hydrolysis. Bioprocesses for generating hydrogen from plant matter will depend upon this knowledge base.

The cost of enzymes is a critical factor for hydrolysis that can be used profitably in the industry. We are utilizing known structure/function relationships of cellulases, hemicellulases, and amylases in order to design biodegradable organic molecules which exhibit the selectivity of enzymes and may have lower costs. Solid acid catalysts and soluble diacid molecules are being investigated. These catalysts are able to operate at much higher temperatures and under conditions unsuitable for enzymes. The application of these catalysts for thermochemical conversion (pyrolysis, solvent conversion, etc.) of plant biomass to bioenergy is also underway at LORRE.

Once primary products such as sugars and lignin derivatives are liberated from lignocellulose, secondary processes are required to convert them into molecules suitable for use as fuels. Biocatalytic approaches, such as fermentation of both glucose and xylose, can produce fuel ethanol. LORRE has developed genetically transformed yeast able the fermentation of both glucose and xylose to ethanol. Genetic modification of yeast to form other bioproducts and biofuels is a future goal. Thermocatalytic processes that operate at higher pressures and may utilize hydrogen as a co-reactant can also be used to convert these primary products into advanced biofuels that have applications for trucking, aviation, and bioproducts.

LORRE’s multidisciplinary work integrates engineering with biotechnology to transition laboratory research into industrial settings that are capable of producing large volumes of biobased fuels. This effort requires concurrent analysis of the economics of bioenergy production systems and the impacts of process improvements. Process modeling, using ASPEN Plus and other software, techno-economic analysis, and prototyping are important parts of LORRE’s activities to apply scientific discoveries to develop technologies that will have a positive societal impact.