RESEARCH

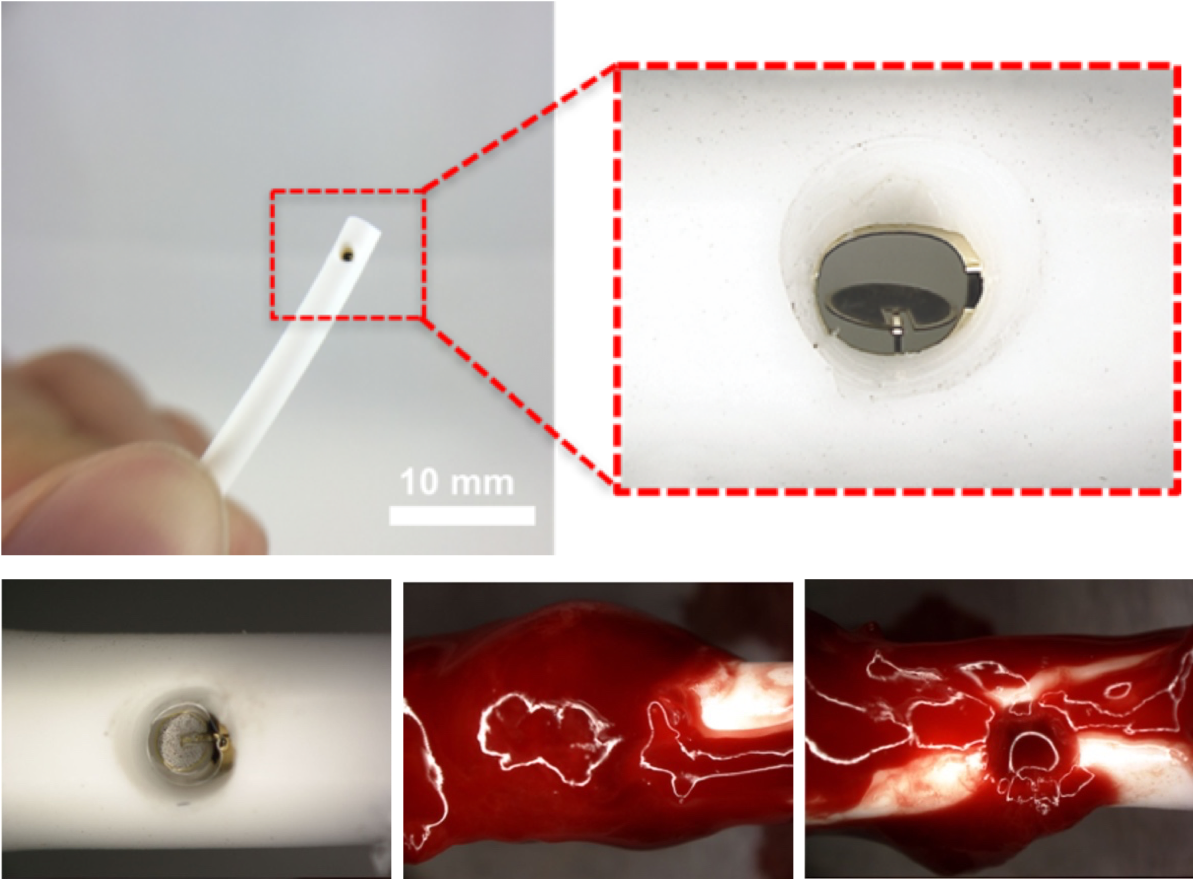

Actuators

Magnetic microactuator enabled self-clearing catheters

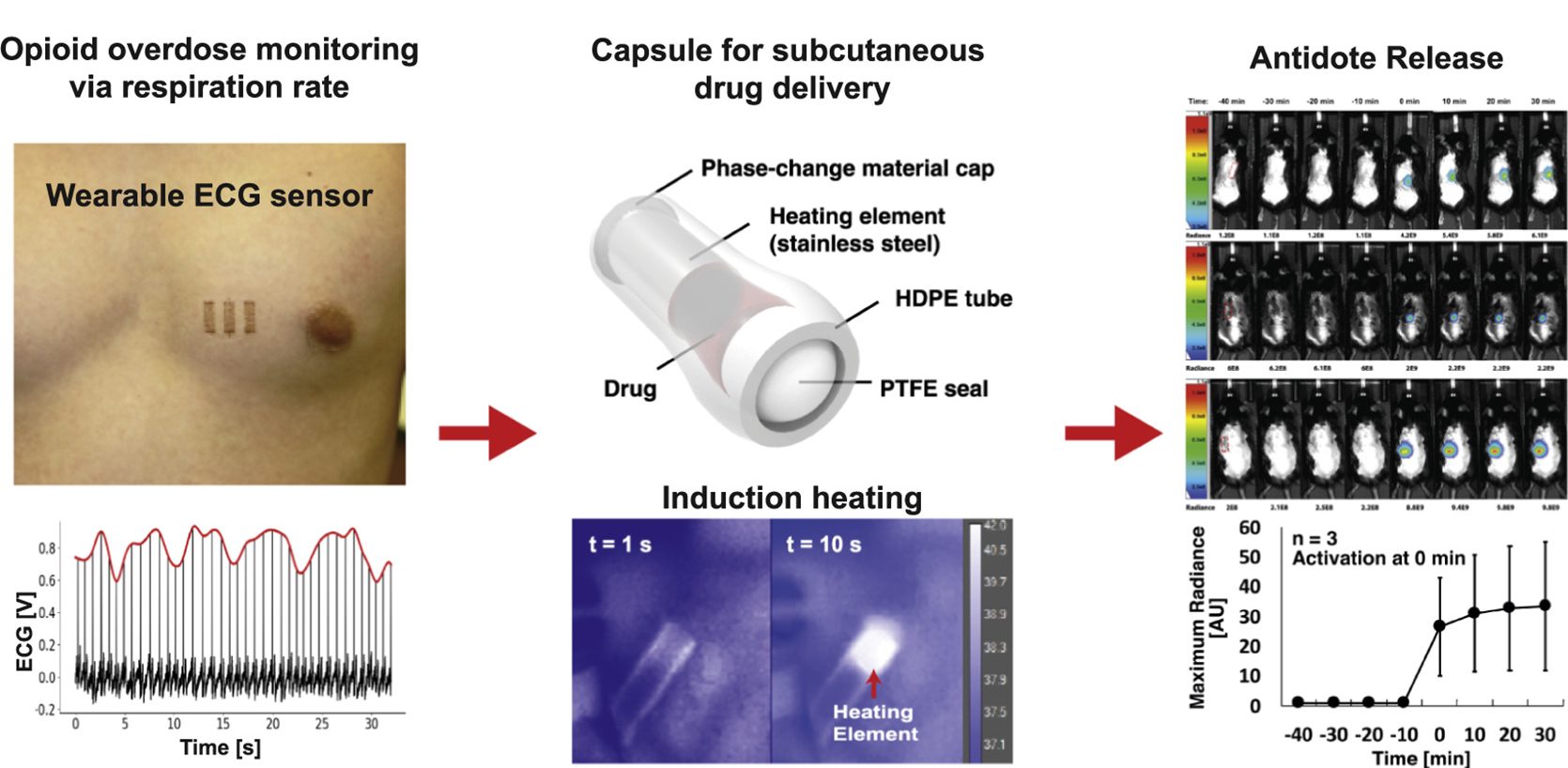

Automatic antidote delivery system for treatment of opioid overdose

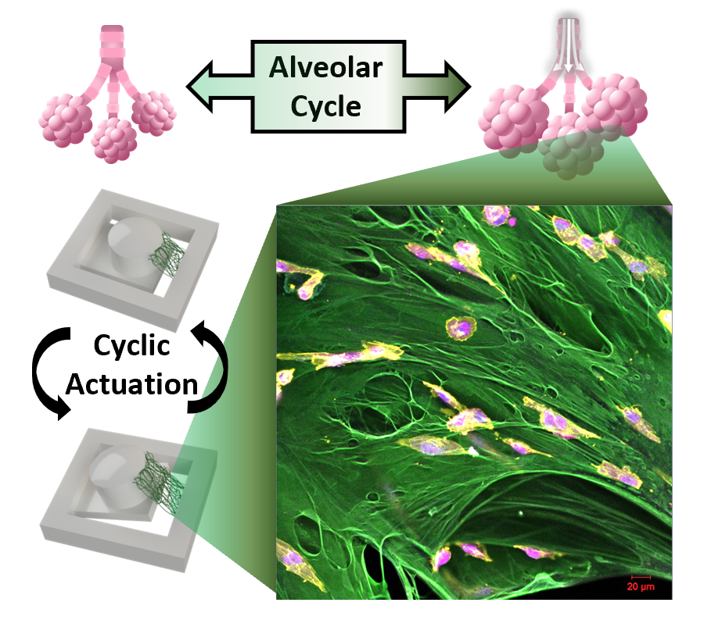

Magnetic actuator-enabled 3D cell culture system for cancer research

Sensors

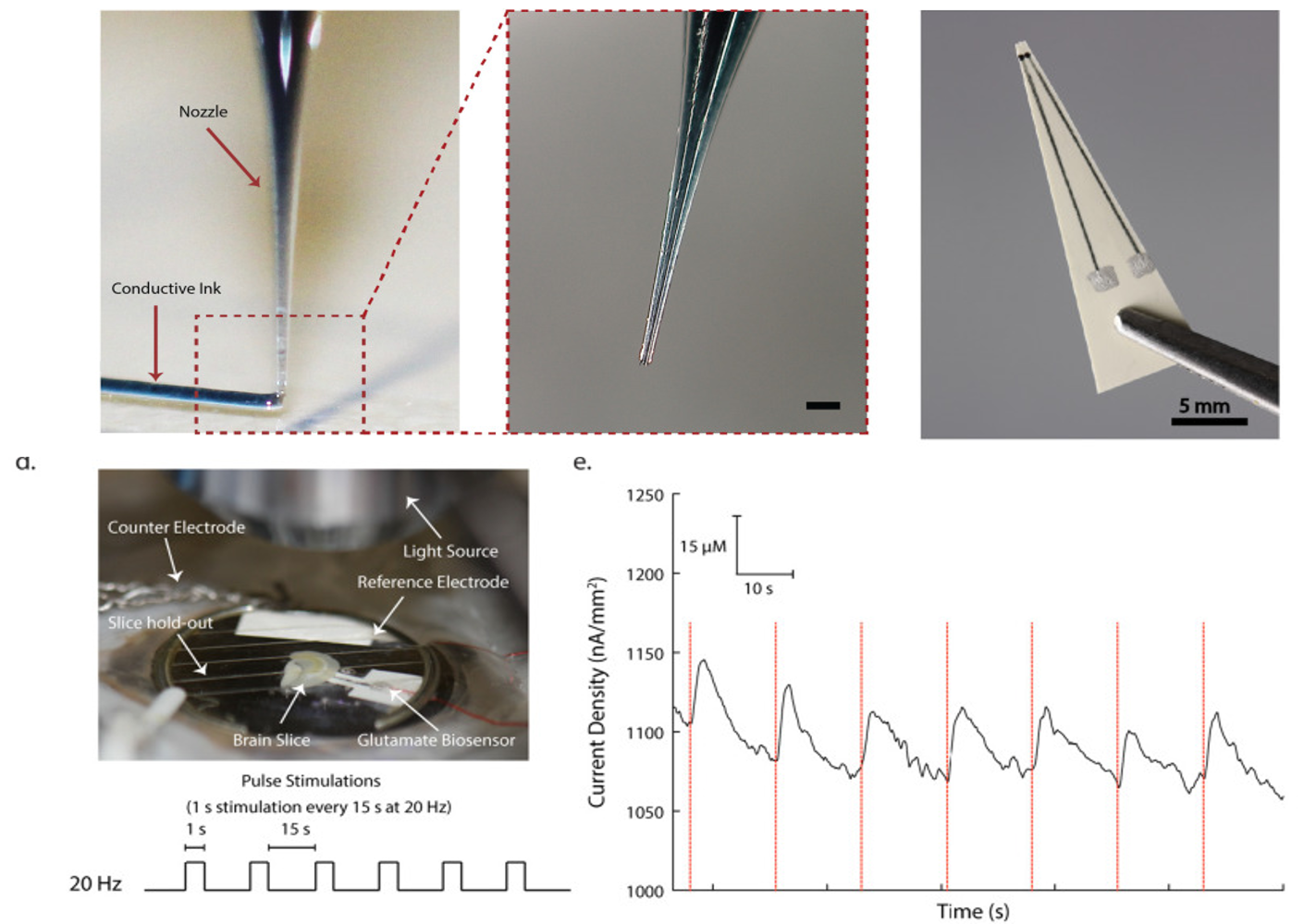

Printable implantable glutamate biosensor using conductive Pt nanoparticle composite ink

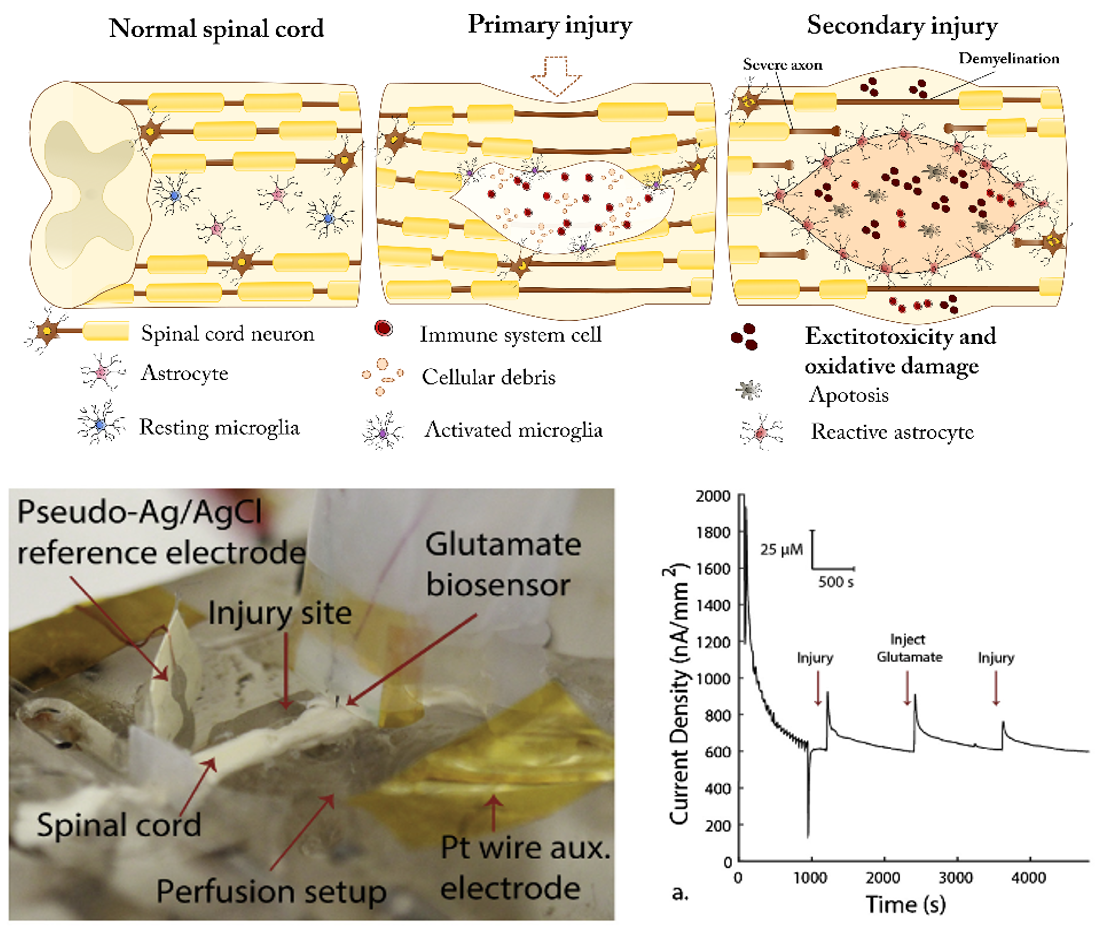

Activated carbon-Pt based printable glutamate biosensor

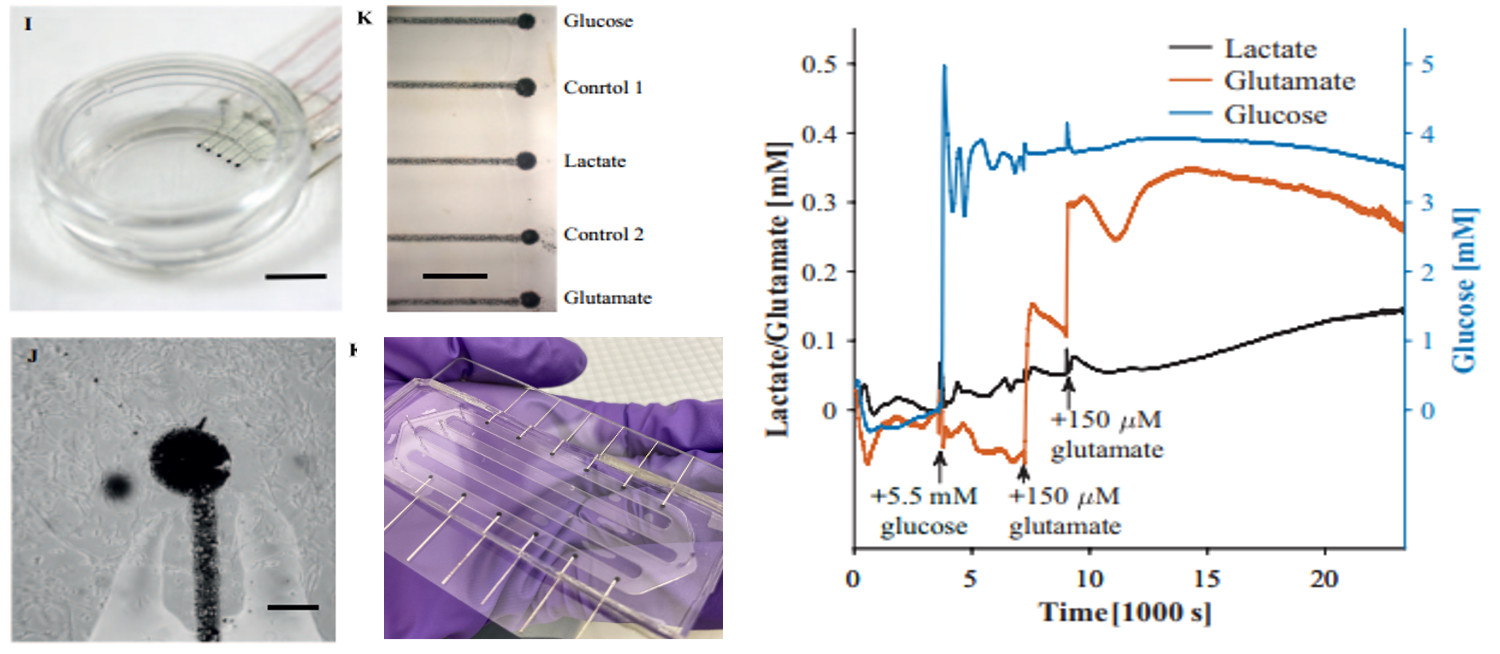

Multi-analyate biosensor array

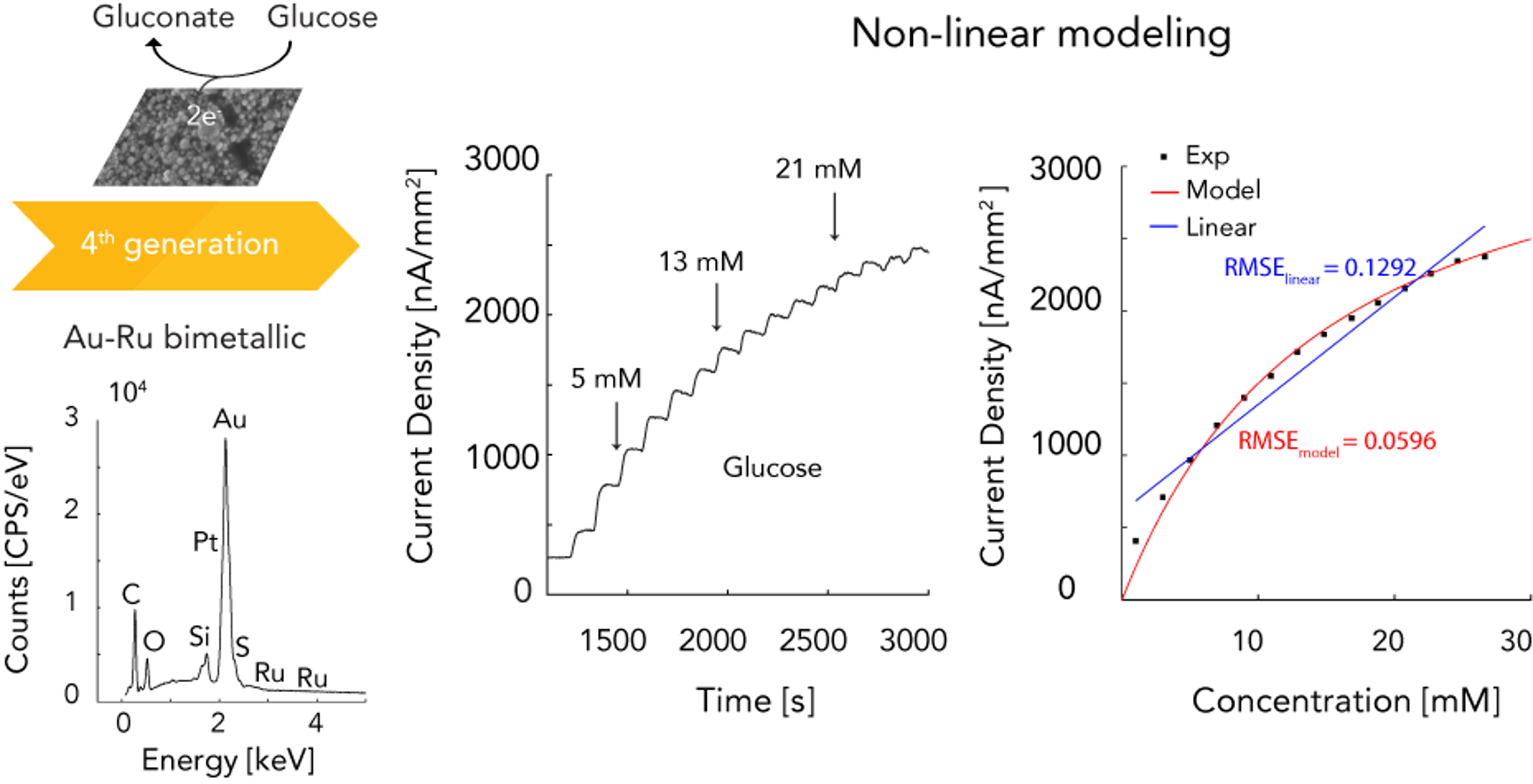

CNT-PtNP based non-enzymatic glucose biosensor and the non-linear modeling

Perovskite-based implantable glutamate biosensor for in vivo cortical monitoring

Anti-biofouling strategies

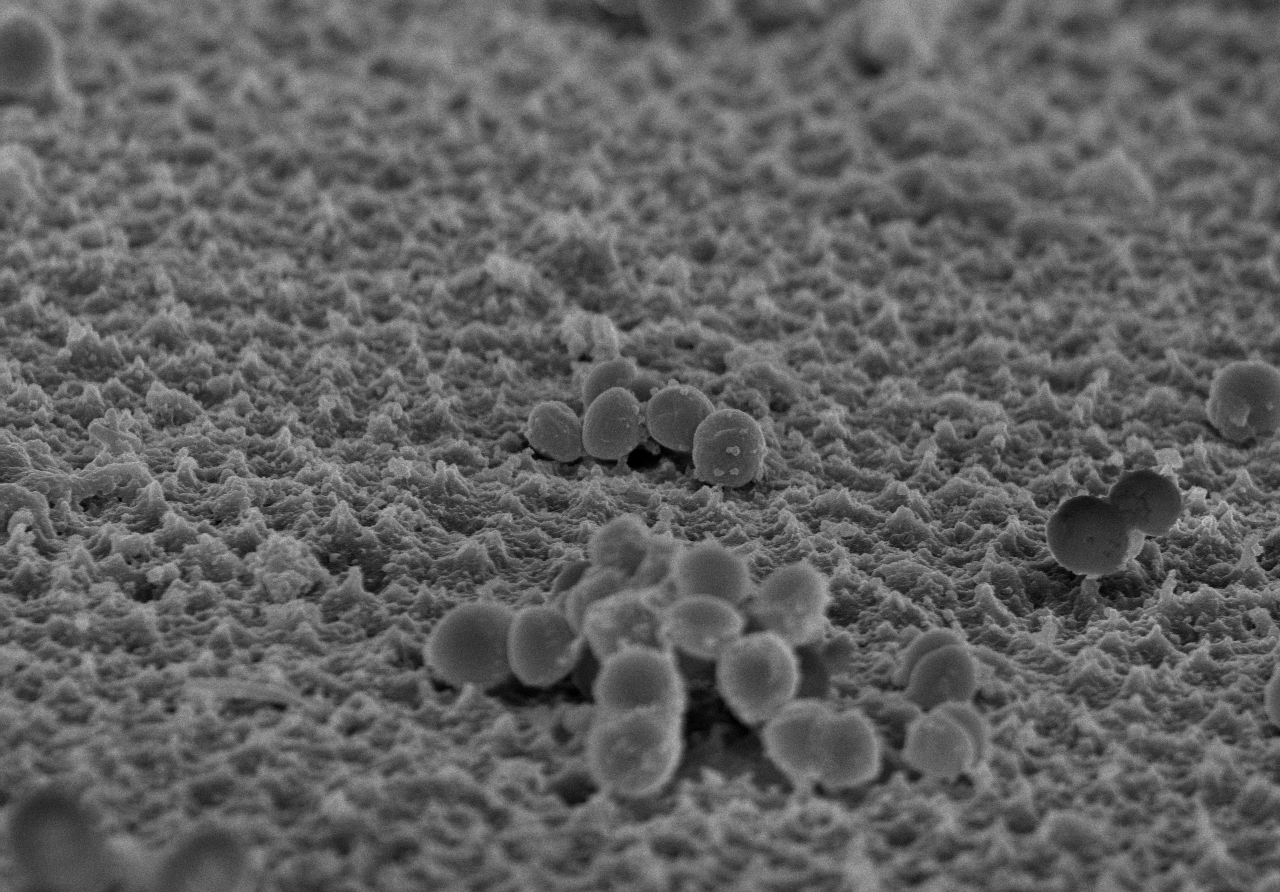

Simple fabrication technique to create a large-scale, anti-inflammatory biomimetic nanotexture

Novel conductive material towards fabrication of anti-biofouling implantable sensors and actuators

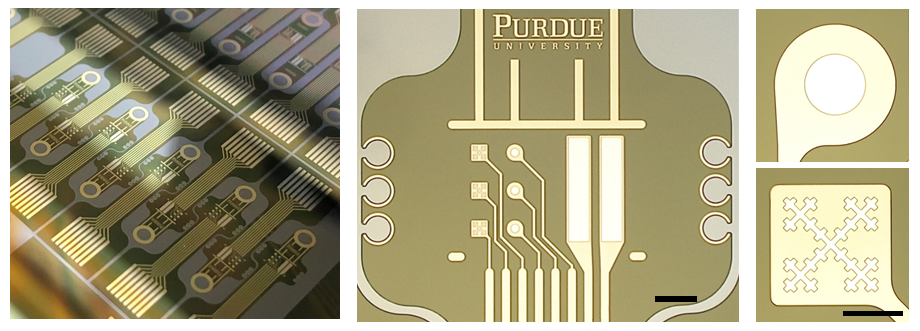

Neural interface

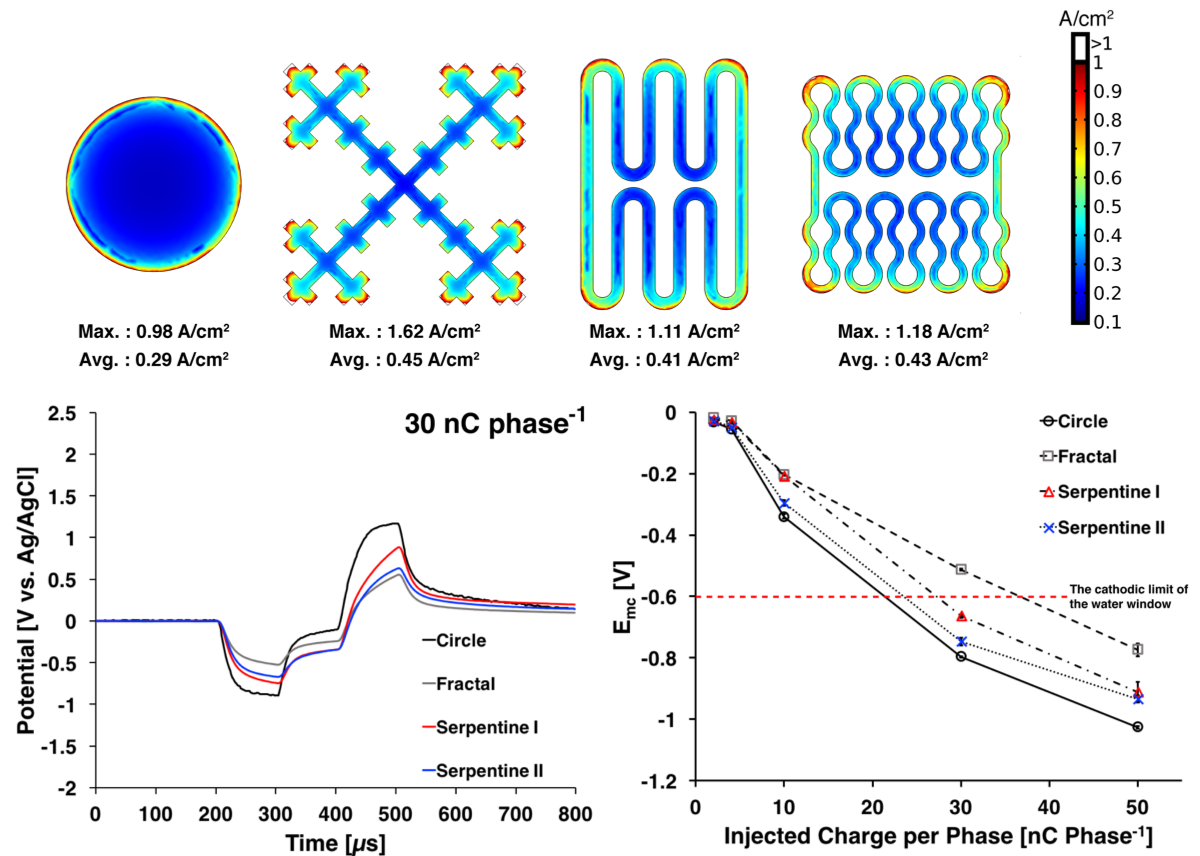

Development of fractal-based neurostimulation micro electrodes

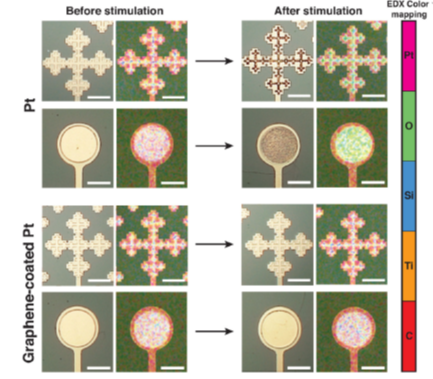

Prevention of Pt-corrosion of micro electrodes using a graphene monolayer

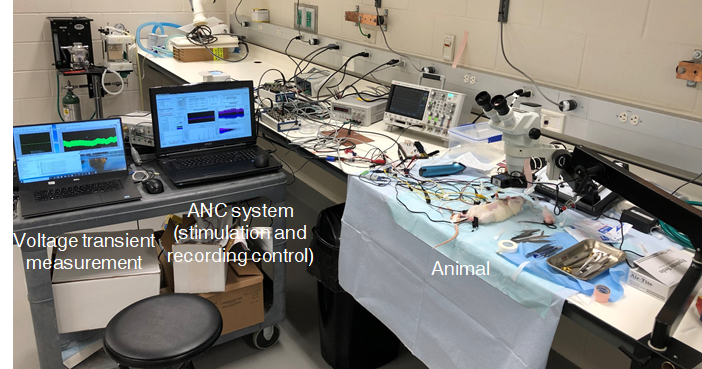

In vivo evaluation of novel neural interfaces