IE's Labs @ Gateway Facility

Lambertus Hall

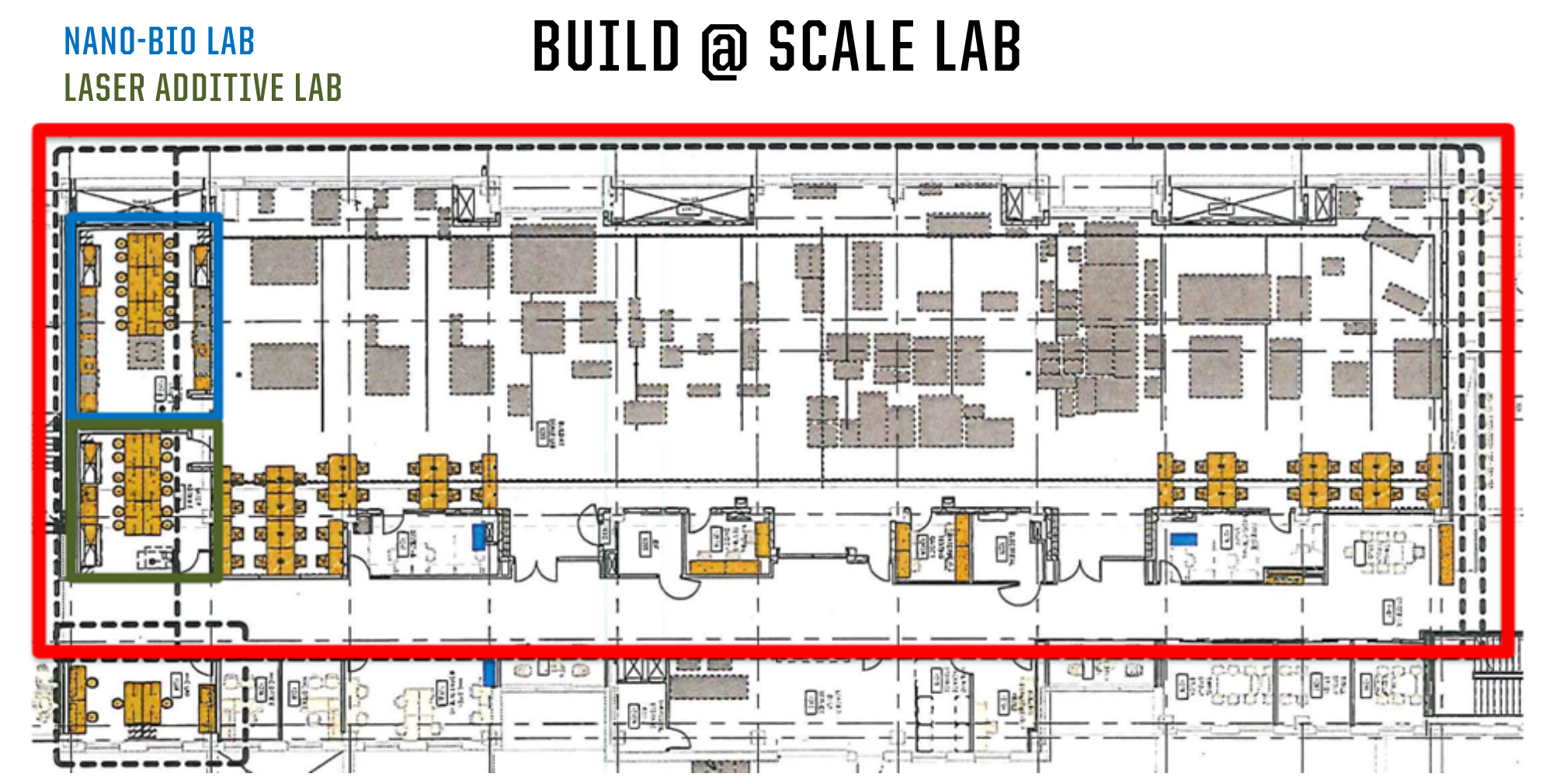

Build @ Scale Lab - LMBS 1263

- To instruct and educate in the methodologies pursuing Industry 4.0, this lab is designed to be fully reconfigurable, fully integrated enterprise platform that envisions data capture and collection from individual machines, prototype manufacturing production lines, roving co-bots and robots, and ASRS (Automatic Storage and Retrieval System). Co-bots and robots will assist operations while retrieving raw material from the ASRS.

- Data captured will be delivered and studied in the 3rd floor Learn-It Labs.

- 10,000 sq. ft. (1st floor); 5-Ton Overhead Bridge Crane allows for all machines to be moved and configured as needed.

- Potential Healthcare Emergency Room Mockup

- Airspace for drone flight while 3D printing part enroute to supply production line

- Currently, teaching a junior level (IE 370) and senior level manufacturing processes lab (IE 470) emphasizing lathe and mill operations, CNC programming, tool cutting forces, tool wear, material hardness measurement, tensile and compression testing, grinding and screw machine operations.

- 37 machines = 3 CNC Mills, 4 CNC Lathes, 1 CNC Chucker Lathe, 2 automatic surface grinders, 1 cylindrical grinder, 26 various legacy machines that drill, mill, shear, turn, saw

- Fully configurable to adapt to faculty research initiatives

-

ZIESS ATOS ScanBox 5120

- The ZEISS ScanBox 5120 measures parts up to 2000 mm in size, making it ideal for larger parts such as interior components of vehicles. However, the ZEISS ScanBox 5120 has also proven its efficiency in casting and forging applications such as the inspection of cast parts, sand cores and models.

Laser Additive Lab - LMBS 1263 C

- Lab facility for IE to expand into: 3D printing (Additive Manufacturing) with fume capture: Deionized (DI) water (minerals removed) wet-lab available for research and instruction

Nano-Bio Lab - LMBS 1263 D

- Lab facility for IE to expand into: Continue development of new applications of nano-bio manufacturing. Commonly referred to as Roll-to-Roll Manufacturing that uses a flexible substrate onto an assembly line and then depositing, cleaning, patterning, or modifying materials on that substrate. Final structures are built up one layer at a time which can be rerolled. Applications include batteries, flexible electronics, fuel cells, sensor materials, fabrics, and paper products.

Dudley Hall

IE Laser Lab - DUDL 3433

-

Lab facility for IE to use laser equipment for various operations such as engraving, cutting, measurement

-

CO2 Engraving and Cutting Machine

- MORN CO2 Engraving, and Cutting Machine offers precise and aesthetical engraving and cutting of non-metal materials. It is suitable for both homeGATEWAY and commercial purposes, and widely used for fine engraving and cutting, hollow carving of acrylic, leather, paper, MDF, rubber, organic board, two-color board, wood board, bamboo products, glass, cloth, resin, plastic, rubber, ceramic tile, crystal, bamboo, organic glass and other non-metallic materials with various texts, graphics, images, trademarks, etc.

-

CO2 Engraving and Cutting Machine

Metrology and Precision Lab - DUDL 3443

- Clean/climate-controlled environment, CMM, laser interferometry, Gauges

- 1,000 sq. ft. (3rd floor)

- Currently, teaching a junior level and senior level manufacturing processes lab emphasizing micro-indention material hardness measurement, tensile and compression testing, height-scale on a surface plate; caliper, micrometer and laser-mic application and operation.

- Capabilities include: Coordinate Measurement Machine (CMM) to measure part characteristics applied to a part print; part profile measurement by projecting a part “shadow” against a measuring scale; roundness test to measure part concentricity; and the afore-mentioned micro-indention material hardness measurement (Rockwell, Brinell, Vickers Scales), tensile and compression testing, height-scale on a surface plate; caliper, micrometer and laser-mic application

Services and Platforms Lab - DUDL 3447

- Healthcare, transportation, security, energy

- Modeling and simulation for research in crisis management, traffic flow, patient-service and care optimization, grid load and grid peak shaving

- Currently, networked computers are primed for use of Simio. A simulation software that creates models and digital twins for applications in production scheduling, training methods, production flow simulations, optimization of storage allocations, resource planning, scheduling methods for outpatient surgery, queuing analysis of wait-times in amusement parks.

- 1,000 sq. ft. (3rd floor)

-

Virtual Reality Cave

- Impact: This VR Cave will be immediately used as a teaching platform by 9 existing IE undergraduate courses (Listed Above), benefiting more than 600 students every year. These courses already have project-based assignments that will be easily adapted to industrial VR environments thanks to the compatibility of the VR Cave with a myriad of open-source Unity 3D scenes. These project-based learning experiences include technical training, complex modeling, 2D/3D floor planning, CAD refinement, and ergonomic and structural analysis. The students will also benefit from project-based teamwork to develop essential competencies, to interiorize knowledge, and to set, prove, and disprove hypotheses by exploration in realistic VR environments. Additionally, giving these courses the capability to enhance their content using VR gamification will transform learning into “experiencing” for the students. Finally, by enabling safe, on-site (virtual) interaction with potentially dangerous tools and processes—such as hot-forming manufacturing systems and welding assembly plants—students will be able to gain an industrial engineering experience unrivaled by any other university.

Leslie J. Raffel Idea, Synthesis and Optimization Lab - DUDL 3465 A&B

- Data, optimization and simulation platforms, collaboratory, project & supply chain management, data science, video conferencing, video taping, location of Industry 4.0 servers.

- 2,000 sq. ft. (3rd floor)

- Fall 2023: Graduate Level Professional Manufacturing Program Instruction Space

- Optimization Lab: As in any Industry 4.0 laboratory, the data collected on the machines in Build @ Scale Lab will be analyzed here. Data collected will be scraped, analyzed, manipulated, and synthesized into an optimization plan. Data can then be used in forecasting, trend analysis, inventory management models, simulation, and dashboard development.

- Senior Capstone Design Course: Group meeting location, client meeting location, intellectual property discussions, project proposal and presentation location.

Cyber Physical Lab - DUDL 3477

- Robotics, table-top robotics, machine vision, gesture-based controls, embedded sensors, RFID

- Lab equipped with fume exhaust snorkels

- 1,500 sq. ft. (3rd floor)

-

Currently, this lab is heaviest in Gateway IE research activities, focusing on

-

Surgical Robotics

- Autonomous, unmanned, medical robots

-

Hand gesture interfaces

- Touchless navigation MRI systems (Gesture Clean)

- Robotic assists that understands gestures (Gestonurse)

- Accessibility in gaming for everyone, gestures for individuals with quadriplegia

-

Assistive technologies

- Telemonitoring using augmented reality

- Bomb dismantling through tactile exploration (collect data: force and chemical composition)

-

Surgical Robotics

Geoffrey and Katherine Cubitt Human Integration and Simulation Lab - DUDL 3485

- Lab facility for Industrial Engineering faculty and students to study biomechanics, biosensors, physical and cognitive work measurement, driving & aviation simulators. This is also an instructional classroom and can be configured for classroom settings.

- 1,500 sq. ft. (3rd floor)

- This lab will allow space for ergonomic study of the human body while under various load scenarios and study of bodily wear associated with repetitive tasks. Load and wear scenarios associated with repetitive manufacturing tasks as in product assembly, or material movement and carry, or cumulative stresses developed in reaching.

- Also, human cognitive decision making under various situations involving attention distractions, environmental elements, or crisis management.

- Also, as the general population ages, what kind of effect does age play in cognitive decision making, driving or flying ability, and reaction time are to be studied in this lab.

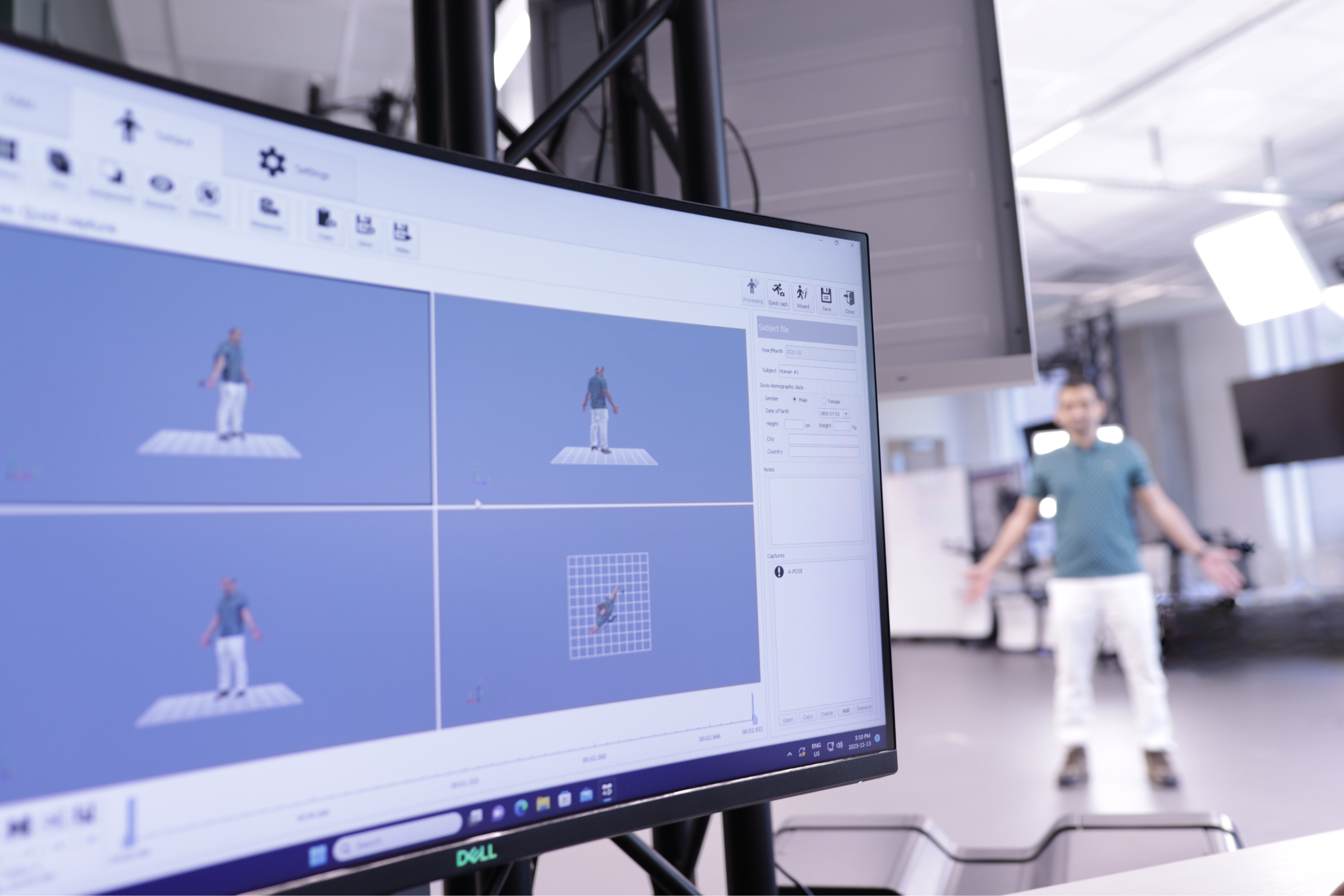

For Motion Capture:

Move4D Scanner System

MOVE4D is a dynamic body scanner and automatic processing software for the generation of watertight and homologous digital human models.

A wire form 4D model (time included) may be immediately generated from the scanner and the “mannikin” may be manipulated and studied in unlimited scenarios. For instance, the optimal way for a person to enter and exit a vehicle, the optimal way for a track and field sprinter to exit from their starting blocks, or the most efficient way for a person to exercise.

Gateway Facility Dedication Ceremony