David Warsinger receives $2.4 million to improve industrial drying with membranes

“Dehydrating chemicals and foodstuffs at an industrial scale is energy intensive and costly,” said David Warsinger, Assistant Professor of Mechanical Engineering. “Imagine running giant ovens up to 600 degrees Fahrenheit, except they’re the size of a house, and running 24 hours a day. These convective drying processes are only 20-60% efficient, with most of the energy wasted as heat. And it's even more wasteful, because they have to cool the chamber to condense and remove the water, before re-heating it again.”

Warsinger’s solution, called MemDry, introduces membranes that selectively remove water vapor, while avoiding heat loss. This removes the need to cool down or condense water to be collected, since the membranes perform this work mechanically. Preliminary results suggest that the advanced materials in these membranes can filter 10,000 molecules of vapor for every molecule of air.

“We can introduce these modules into already-existing convective drying systems,” said Warsinger. “Our baseline studies show that this will multiply their energy efficiency by a factor of three.”

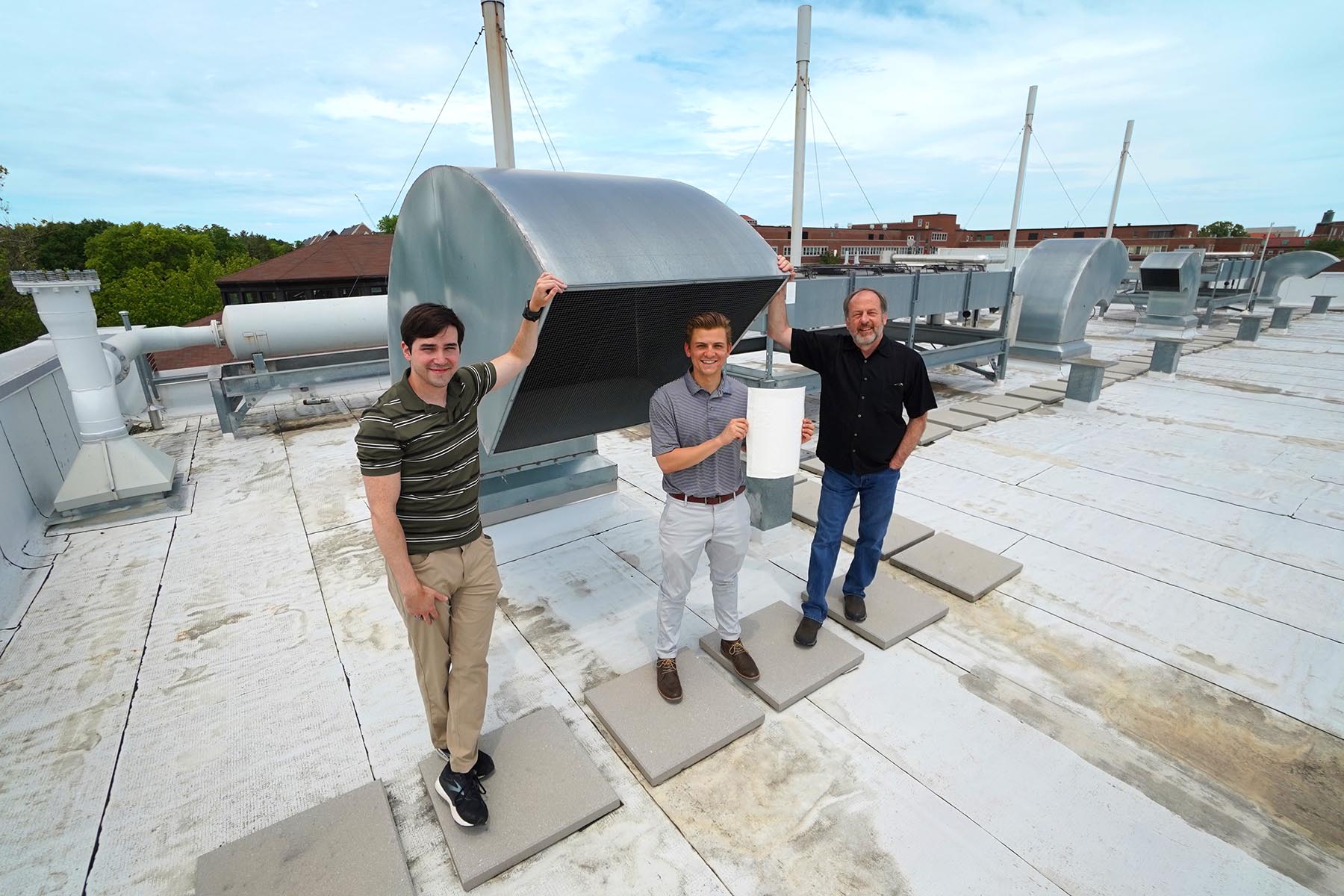

Warsinger’s team proposed and modeled the membrane-based system in 2021 as a means to dehumidify the air in building HVAC systems. Now, the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) has awarded the team a $2.4 million grant to demonstrate a similar system for industrial drying.

Partners in the project are James E. Braun, Herrick Professor of Engineering, and Director of the Center for High Performance Buildings; Davide Ziviani, Assistant Professor of Mechanical Engineering, Associate Director of the Center for High Performance Buildings; and Inventherm, a research and development firm in Baton Rouge, Louisiana, who will focus on the compressor systems. Research will be conducted at the Birck Nanotechnology Center and the Ray W. Herrick Laboratories at Purdue University, home to the largest academic HVAC lab in the world.

“MemDry will have a multiplying effect,” said Warsinger. “By introducing this simple change, industrial drying processes will be faster, cheaper, and more energy efficient. And because 95% of their energy currently comes from fossil fuels, we’ll also be reducing their carbon footprint. Reducing energy demands while also reducing costs is a win-win for everybody.”

Patent applications for this system have been filed via the Purdue Research Foundation Office of Technology Commercialization. This research is supported by the Center for High Performance Buildings at Purdue University (project number CHPB-50-2020).

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: David Warsinger, dwarsing@purdue.edu

Vapor-selective active membrane energy exchanger with mechanical ventilation and indoor air recirculation

Andrew J. Fix, Bryan C. Pamintuan, James E. Braun, David M. Warsinger

DOI: https://doi.org/10.1016/j.apenergy.2022.118768

It is widely known that increasing outdoor air ventilation rates in buildings can help improve indoor air quality and mitigate the spread of diseases. However, cooling and dehumidifying outdoor air requires significantly more energy than treating indoor recirculated air. Recent developments in water vapor-selective membranes, which use a vapor partial pressure gradient to remove water vapor from air, offer a unique opportunity to provide highly efficient dehumidification in HVAC systems that can justify high outdoor air ventilation rates without drastic increases in energy consumption. This work presents an analysis of a novel membrane HVAC system referred to as the Active Membrane Energy Exchanger (AMX), which couples a refrigeration cycle with selective membranes to simultaneously cool and dehumidify air. While past selective membrane dehumidification systems have been isothermal, the AMX is the first to deliberately target non-isothermal operation by combining membrane dehumidification and active heat exchange. A thermodynamic model is developed for the AMX in a system that uses both outdoor air ventilation and indoor air recirculation (AMX-R) to elucidate the limitations around increasing ventilation rates. This study is among the first to consider recirculation for selective membrane processes, rather than only 100% outdoor air. The AMX-R can achieve up to 50% cooling and dehumidification electricity savings in warm and humid climates under current ventilation standards. Furthermore, ventilation rates can be nearly tripled with the AMX-R while consuming similar amounts of energy as conventional HVAC systems. Lastly, the incorporation of EnergyPlus building simulations for 114 US cities shows that the AMX-R has the greatest potential in the southern regions of the US.