Research

Higher energy-content jet blending components derived from Ethanol

Purdue-LanzaTech-PNNL team’s work proposed here targets the understanding of current and new cycloalkanes for use as a jet fuel. Through catalyst development, this project will provide a route to control the cycloalkane/n-alkane/iso alkane content of a next-generation fuel with minimal or no aromatic content.

Next Generation Fuels - II

The NAWCAD Fuels Team has identified a capability gap related to identifying the root cause of fuel instability. We propose to address this issue by developing a validated analytical method for the identification of oxygenate classes in fuels. Machine learning approaches will be developed for the fast and accurate interpretation of the data

Design of Next Generation Renewable Fuels

Aviation fuels, unlike other liquid transportation fuels, must be able to provide lubrication and cooling to an engine, in addition to being the power source of the aircraft. Hence, fuels come into contact with multiple components of gas turbine engines. Original engine and aircraft manufacturers need to assure the safety and durability of the engine for up to 30 years. Thus, ASTM (formerly known as the American Society for Testing and Materials) governs the deployment of aviation fuels via multiple specifications (ASTM D4054, ASTM D1655 and ASTM D7566). These standards define certain compositional limits for the fuels for safe performance. As long as the candidate fuels satisfy these limits, they may be deployed. However, there is currently a knowledge gap on the detailed chemical compositions of fuels. Hence, the approval process only takes into account the "permitted" and "restricted" compounds, such as aromatics. In addition, the cumbersome "fuel testing" protocol (ASTM D4054) may take up to 5 years and may cost over $30 million. Our research aims to correlate fuel composition (agnostic of the origin) to the "fit for purpose" and "performance" criteria, such as combustion efficiency and emissions. Further, we are concerned about possible degradation of the metallic engine parts and ceramic coatings by impurities in the fuel. This issue is especially relevant to biofuel impurities such as phosphorus, sodium, potassium, and oxides of alkaline and alkaline earth metals. The types of impurities depend on the biofeedstock utilized. Office of Naval Research is our sponsor who is currently funding us for the next three years.

News:

News:

Kilaz’s new Fuel Laboratory of Renewable Energy already making mark in interdisciplinary research

Aviation biofuel research could decrease development costs, increase safety for firefighters

Six new Purdue research projects focused on power and energy funded though U.S. Navy partnership

Kilaz researching renewable fuels for Navy

Kilaz focuses research on aviation biofuels

U.S. Navy awards Purdue $3 million to advance alternative energy-related research

Project deliverables include:

-

qualitative analysis utilizing two-dimensional gas chromatograph with time-of-flight mass spectrometry (GCxGC TOF/MS)

-

quantitative analysis utilizing two-dimensional gas chromatograph with flame ionization detector (GCxGC FID

Analysis of Hydrothermal Liquefaction Process from Plastics to Liquid Fuels

Kilaz research team collaborates with Dr. Linda Wang, the Maxine Spencer Nichols Professor in the Davidson School of Chemical Engineering for the conversion of world's plastic waste into clean fuels. Dr. Wang's invation has the potential to convert 90 percent of polyolefin waste into many different products, including pure polymers, naphtha, fuels, or monomers. We are responsible for participating in the optimization of this conversion process to produce high-quality gasoline or diesel fuels. FLORE accomplishes this task via executing a maltitude of analyses including but not limited to: detailed chemical composition via GCxGC-TOF/MS & GCxGC-FID, distillation, density, viscosity, net heat of combustion.

Non-Destructive Detection and Authentication of Electronics

Kilaz research team collaborates with Dr. Eric Dietz, Professor in Computer and Information Technology and Director of Purdue Homeland Security Institute on this project. Our team has developed a partnership with Todd Jordan, the owner of Jordan Detection K9, that has the potential to offer an alternative method to the existing destructive testing of electronics components. Kilaz research team explores the potential for determining detection limits for K9 in electronics detection that give insight into well trained K9 levels and the potential for developing electronics sensors for electronics detection using the methodology employed by K9 detection teams.Our two-dimensional gas chromatography eqquiped with both mass spectrometry and flame ionozation detector enable our team diagnostic qualitative investigation followed by a quantitative analysis method development.

Drop in Aviation Fuels Fire Safety

US firefighters were challenged with the introduction E85 fuels in 2008 as a large number of material and tactical changes were necessary by the fire service to ensure that interactions with synthetic fuel combustion and that typical firefighting foams did not lead to dangerous situations for firefighters. The variety of drop-in aviation fuel blends with synthetic pathways introduces significant possibility for similar differences negatively impacting the safety of the public and first responders. The FAA ARFF (Aircraft Rescue and Firefighting division), needs to respond in a very short time and extreme urgency to preserve lives. This requires characterization of the response challenges and training to provide incident commanders with awareness of the changes needed to make timely, effective and safe adjustments to tactical response. Recent advancements in alternative jet fuels have brought to our attention the need to investigate the efficiency of currently utilized fire extinguishing agents at the airports and aircraft. Firefighting foam has been the most commonly used extinguishing medium in the past years. Still, there are multiple varieties in the types of concentrates applied as well as the standards by which the foams get approved. International Civil Aviation Organization (ICAO), United Kingdom Civil Aviation Authority (CAA), FAA (Mil-F-24385), and Environmental Protection Agency (EPA) all have their test protocols for evaluating the capability of these foams. This results in multiple issues with technical variations. Thus, there is a need for evaluating the current certification protocols and specifications to alleviate compatibility concerns. The situation is further complicated by the recently approved alternative aviation fuels as the chemical differences are expected to impact the foams’ firefighting properties. With FAA’s goal of “1 billion gallons of sustainable drop-in jet fuel per year by 2018” in mind, Gozdem research team is currently tackling this imminent challenge by determining the chemical properties that affect the performance and mapping them to the fuel burn characteristics such as fire spread and flammability.

Alternative Aviation Fuels Fire Safety

Aviation biofuel research could decrease development costs, increase safety for firefighters

Project deliverables include:

-

Quantitative and qualitative analysis of liquid transportation fuel

-

Flash point and Net heat of combustion testing

GCxGC Column Chemistry

Kilaz research team, in collaboration with U.S. Naval Research Labs and Naval Air System Command, investigating the specifics on column chemistry for aviation fuel analysis. Our efforts are focused on streamlining the analytical techniques for optimal compounds separation. For this purpose we will be utilizing GCxGC MS and GCxGC FID, both with thermal modulation.

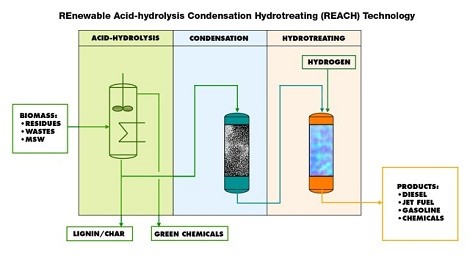

Renewable Acid-hydrolysis Condensation Hydrotreating technology (REACH)

The first step in the REACH process is to treat non-food biomass in an acid hydrolysis unit to create a mixture of non-sugar intermediates in high yields. The intermediates are consecutively processed in a condensation unit into usable carbon chains. The final step is a hydrotreating process to deoxygenate the intermediates. The final fuel products are drop-in blend ready for use in the general liquid fuels market. High value chemicals are also produced and could be sold into higher value markets. The process is indifferent to the biomass feedstock and both cellulose and hemi-cellulose are processed at the same rate with the same cost structure. The process is significantly faster than many other biofuel production methods, has lower capital and operating expenses, and does not rely on food crops for feedstock. Our group is the co-recipient of a $4.6M Department of Energy Cooperative Agreement for studies towards a successful REACH pilot plant that can produce 800 gallons of sustainable jet fuel per day.

Sustainable biofuels within reach