Pankow Materials Laboratory

MTS Insight 10 - Universal Tensile Machine

Physio-Chemical and Microstructural Characterization

- Q5000

- Pressure Plate

- Isothermal Calorimeter

- Atomic Absorption Spectroscopy

- BET Surface Area Determination

- Conduction Calorimeter

- Electrical Impedance Spectroscopy (EIS)

- Energy Dispersive X-Ray Analysis (EDX)

- Image Analysis

- Infrared Spectroscopy (FTIR)

- Ion Chromatography

- Mercury Intrusion Porosimetry (MIP)

- Optical Microscopy

- Scanning Electron Microscopy (SEM)

- Thermogravimetric Analysis (TGA)

- Differential Scanning Calorimeter (DSC)

- Ultraviolet Visible Spectroscopy (UV)

- X-Ray Diffraction (XRD)

- Zeta Potential

Durability Testing

- Rapid Resistivity Meters

- Electrical Migration Test

- Dual Ring

- Oxygen Permeability Instrument

- Oxygen Diffusivity Instrument

- Permeability, Ion Diffusion, and Corrosion

- Chloride Transport

- Chloride Migration Test

- Chloride Diffusivity

- Rapid Chloride Permeability

- Freeze-Thaw Chamber

- Hardened Concrete Air-Void Analysis System

- Restrained Ring Testing and Data Acquisition

- Linear Passive Restraint (Munich Testing Frame)

- Plastic Shrinkage Cracking

Mechanical Testing

- MTS Insight 10 - Universal Tensile Machine

- 30 Kip Closed-Loop Servo-Hydraulic System

- 110 Kip Closed-Loop Servo-Hydraulic System

- 60 Kip Hydraulic System

- 100 kip Open-Loop Electrical System

- 120 kip Hydraulic System

- 250 kip Open-Loop Hydraulic System

600 Kip Hydraulic Compression Testing System

- Extensometers

- LVDT's

- Impact Testing

- Hardness

Non-Destructive Testing

- Acoustic Emission with Waveform Analysis

- Schmidt Hammer

- Ultrasonic Resonant Frequency

- Non-Contact Laser Displacement System

- Ultrasonic Pulse Velocity

- Image Analysis with X-Y Stage

- Photoelasticity

Pavements Testing

- Accelerated Pavement Testing (APT)- Indiana Department of Transportation (INDOT)

- Tire Pavement Testing Apparatus - Institute for Safe Quiet and Durable Highways

Specialized Computer Software

- ARC2 - Automated Analysis of Restrained Rings for Creep and Cracking

- ROD - Rate of Concrete Property Development

- CPCRM - Cost and Performance Comparison of Repair Materials

Specimen Preparation/Conditioning

- Vacuum Saturation Equipment

- Relative Humidity Control Chamber for Testing Lightweight Aggregate Absorption

- Microbiological Growth Chambers for Evaluating Microbially Induced Concrete Corrosion (MICC)

- Concrete Mixers

- Maturity

- Temperature Match Curing

- Mortar Mixing

- Concrete Cutting and Polishing

- Aggregate Preparation and Testing

- Ovens

- Temperature/Humidity Chambers

- Vacuum Pumps and Chambers

The standard restrained ring test (ASTM 1581-09) is a simple, economical method to evaluate a concrete mixture's susceptibility to develop shrinkage cracking when it is restrained. However, the standard test only provides restraint against samples that shrink at isothermal temperature and cannot be used to characterize materials undergoing expansion. Further, the conventional restrained ring test is difficult to apply in cases in which the concrete undergoes large variations in temperature since the restraint changes dimension under heating and cooling. The Dual Ring is a new tool that was designed to overcome both of these limitations. The new dual concentric ring test provides restraint for both shrinkage and expansion, and has incorporated the ability to study thermal stresses by using a restraining ring having a very low thermal expansion coefficient.

Characterization of X-ray diffraction is a direct result of crystal structures being present in the cement-based sample under study. When illuminated by an x-ray source, crystalline material will generate x-ray diffraction peaks. The peak positions are described by the crystal unit cell parameters, and the peak intensities are given by the placement of the atoms in the unit cell. The peak widths are a result of two parameters, finite crystallite sizes and micro-stress within the crystallites. As such, the parameters that define different a crystal structure can be simply accessed from an x-ray diffraction pattern. Each mineral type is defined by a characteristic crystal structure, which will give a unique x-ray diffraction pattern, allowing rapid identification of minerals present within the concrete sample. The detection and quantification of the various minerals within the sample is the first step in understanding the nature of the sample. Once the minerals have been identified, changes in the mineral morphology and crystal structure are indicative of the various physico-chemical processes in concrete due to the interaction of raw materials or changes in exposure conditions.

An isothermal calorimeter is commonly used to determine the heat released from the cement hydration. A small cement paste/mortar sample is poured in a glass ampoule and then placed in the calorimeter. The heat released is compared to that released from an inert sample. This technique allows for the assessment of the extent of cement reaction with water, and therefore permits to evaluate the effect that other cementitious materials and admixtures have on the cement reaction.

Oxygen Permeability Instrument

The oxygen permeability instrument is a falling head permeameter, usually known as South African apparatus. It involves the measurement of the steady unidirectional flow of gas through the concrete cylindrical specimen due to the presence of a pressure gradient between the upper and the lower side of the sample. Indeed, the bottom surface is in contact with the oxygen contained in the vessel at a known pressure, while the top surface is at the atmospheric pressure. The gas flow is quantified monitoring the pressure drop with time. The sample is inserted in a rubber collar, placed in the upper cell and then compressed in order to ensure a good sealing of its sides. The pressure in the cylinder is allowed to reach approximately 100 kPa initially.

This instrument measures the oxygen diffusivity of concrete (or mortar) samples generating a steady state system where the oxygen and nitrogen, at the same temperature and pressure, inter-diffuse at different rates creating unequal pressure locally; the mass migration ensures that the overall pressure remains uniform. The specimens have to be fitted in a silicon rubber ring that is compressed to provide an air-tight grip onto the sample. The test is performed by exposing one surface of the disc to a stream of pure oxygen and the opposite face to a stream of pure nitrogen at the same pressure. Oxygen and nitrogen counter diffuse through the sample and the oxygen concentration in the outlet cell is measured with a zirconia analyzer.

A moisture analyzer is used to determine moisture desorption isotherms. A saturated cement paste/mortar sample is placed in a sample holder and isolated in a moisture chamber with controlled temperature and humidity. The humidity is then decreased in a controlled fashion forcing the material to dry out. This technique allows for the determination of pore size distribution and type of microstructure of porous materials such as hydrated cement specimens and lightweight aggregates. Lightweight aggregates are used in concrete for internal curing purposes. This technique permits the evaluation of the desorption properties of these materials.

Electrical migration tests have gained in popularity as a quicker method of measuring transport properties. These tests include the rapid chloride penetrability test, ASTM C1202, the non-steady-state migration experiment, NT BUILD 492, and numerous other methods. These methods monitor the current passed through a sample submerged in a solution. These methods give a good indication of a materials transport properties.

The world-class experimental set-up at Purdue for migration tests allow for continuous monitoring of up to eighteen specimens for current and temperature.

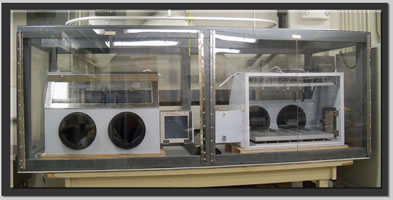

Accelerated Pavement Testing (APT)- Indiana Department of Transportation (INDOT)

The INDOT – Purdue University APT facility is located at the INDOT Research Division in West Lafayette, IN. The APT is housed in an approximately 2,000 square feet (185 square meter) environmentally controlled building. The APT facility is composed of a testing pit area of 20 foot (6.1 m) wide by 20 foot (6.1 m) long by 6 foot (1.8 m) deep, a loading mechanism and control and monitoring equipment. The APT carriage (picture on the left) can be equipped with either a full-size, dual-tire truck wheel or a super-single, half-axle assembly. The tire can be inflated at various pressures. This setup allows speeds up to 5 mph (8 kph). The APT loading mechanism uses a system of four air pistons that maintain a constant force up to 20,000 lbs (89 kN). This load can be programmed either in static or dynamic modes. These cylinders also allow the wheels to be raised and returned to the start-up position of the test pad if used in one direction type of testing.

The APT facility is used in projects of different kind (i.e. asphalt, concrete). The picture on the right shows a concrete pavement instrumented with dowel bars, strain gages and thermocouples that will be loaded. Temperature and deformations of the pavement will be measured to calculate stress distributions and damage. This research is currently being executed and studies the conditions of the pavement at the moment that it is opened to construction traffic loads.

Electrical Impedance Spectroscopy

Electrical Impedance Spectroscopy (EIS) is a system that allows for the measurement of the electrical response across a range of frequencies using alternating current. This technique is widely accepted as the most precise method of determining the bulk resistivity of concrete materials. Implementation with the Automated Electrical Monitoring Systems (AEMS) allows for continuous monitoring of test specimens and can be used to determine time of setting and can give an early indication of the developing microstructure of a mixture.

The electrical properties of concrete are a very exciting new area being investigated for implementation for mixture characterization by many different agencies. The main benefit is the relatively low equipment cost compared to other methods. Work at Purdue has been using many of the meters that might potentially be used in the implementation of very-rapid electrical testing.

The porosity and degree of saturation of concrete materials govern many aspects of their durability. The vacuum saturation machine is one of the most effective ways of testing porosity and saturation. The equipment at Purdue uses a programmable system to evaluate differing vacuum levels.

Relative Humidity Control Chamber for Testing Lightweight Aggregate Absorption

Internal curing using porous lightweight aggregate is based on the ability of the aggregate to release water inside of concrete as cement hydration occurs. Internal relative humidity within the concrete plays a large role in how much water can be released by the aggregate. By storing lightweight aggregates in varying relative humidities, the absorption and desorption characteristics of the aggregates can be observed.

MTS Insight 10 - Universal Tensile Machine

The Universal Tensile Machine (MTS Insight 10 and accessories) provides the capability to perform tensile, bending, torsion, compression, peel and tear tests up to 10KN loading conditions. Load vs Displacement data is obtained as the main output from the equipment, while by the use of extensometers, LVDT, strain-gauges or specialized imaging systems (Digital Image Correlation, ImageJ, etc.) detailed test data can be acquired. Fracture crack propagation and fracture toughness tests on flat and patterned double cantilever beam experiments have been successfully performed. Viscoelastic tensile tests on shape memory polymers or characterization CNC/NFC-reinforced cementitious materials under compression tests can be named within some of the other active projects begin performed with this equipment. This equipment supports research in the Computational Multi-Scale Materials Modeling Laboratory under the direction of Prof. Pablo Zavattieri.

Microbiological Growth Chambers for Evaluating Microbially Induced Concrete Corrosion (MICC)

Several bacterial species are responsible for microbially induced corrosion (MICC) observed in wastewater conveyance systems, wastewater treatment plants and septic tanks. In these chambers optimal growth conditions can be achieved by controlling temperature, humidity, nutrient supply, and hydrogen sulfide gas content. Through precise experimental control, years of corrosion can be achieved in a matter of months and MIC can be investigated in a practical time period.

Atomic Absorption Spectroscopy

The atomic absorption spectrometer uses the principals of quantum chemistry to detect the presence of certain metals (i.e., iron, aluminum, copper, etc.) and determines the concentration of those metals in samples. The laws of quantum mechanics shows that atoms do not increase their energy levels gradually. An atom goes directly from one state to another without going through intermediates. These "quantum leaps" are referred to as transitions. The transition from the ground state (Eo) to the first excited state (E1) requires some form of energy input. This energy is absorbed by the atom. When this energy absorption takes place in the presence of ultraviolet light, some of that light will be absorbed. This UV absorption occurs at a specific wavelength. Each element in the periodic table will absorb a specific wavelength of UV light. The relationship between the energy transition and the wavelength can be described by:

where h is Planck's constant. Atomic absorption spectrometer uses this relationship to determine the presence of a specific element based on absorption at a specific wavelength.

This instrument can be used to determine multipoint and single point BET surface area of a catalyst, total pore volume, average pore radius, pore size distribution, sample volume and density, and external surface area. BET surface area is an important means of correlating the activity of a catalyst to its pore structure. The surface area measurement in this system is based on the volume of nitrogen uptake by a known amount of sample at liquid nitrogen temperature. An outgassing station with a heating mantle is used to degas the sample prior to measurement. Sample cells can be interchanged quickly between the outgassing and measuring stations using quick-connect fittings that seal them from the atmosphere. Nitrogen is adsorbed onto the sample at -196 oC by flowing a nitrogen-helium stream of known composition over the sample. The nitrogen desorption peak is measured by a calibrated thermal conductivity detector and integrated to yield the volume and mass of nitrogen adsorbed.

Mercury Intrusion Porosimetry (MIP)

Used for the determination of Mean Pore Size, Surface Area, Pore Size Distribution, Bulk Density, Total Pore Volume, Absolute Density, and Particle Size Distribution. Porosimeter is a versatile and accurate instrument used to determine properties such as Pore size distribution; total pore volume, surface area, and bulk and absolute densities of solid and powder samples.

Thermogravimetric Analysis (TGA)

This technique registers the quantity and speed of a change in weight as a function of time or temperature. The TGA technique is used for better understanding of the composition of multicomponent systems, oxidations of metals and non-oxide ceramics evaporation of binder from a powder.

Differential Scanning Calorimeter (DSC)

The DSC consists of two separate furnaces for the sample and the reference sides. The system can be divided into two control loops, the average temperature loop and the differential temperature loop. The average temperature loop ensures that the sample and reference sides are heating at the programmed rate. The differential temperature loop maintains identical temperatures between the reference and sample pans regardless of the different amount of heat needed to enter the sample side. This process ensures that the sample is always kept at the same temperature of the reference regardless of any changes that occur within the sample requiring more or less heat flow. When an endothermic process occurs such as softening or melting, more heat is added to the sample side relative to the reference to make up for a difference in temperature. With an exothermic process less heat is added to the sample relative to the reference side.

Energy Dispersive X-ray Analysis (EDX )

An energy-dispersive x-ray analyzer (EDX) is a common accessory, which gives the scanning electron microscope (SEM), a very valuable capability for elemental analysis. The electron beam in an SEM has an energy typically between 5,000 and 20,000 electron volts (eV). The energy holding electrons in atoms (the binding energy) ranges from a few eV up to many kilovolts. Many of these atomic electrons are dislodged as the incident electrons pass through the specimen, thus ionizing atoms of the specimen. Ejection of an atomic electron by an electron in the beam ionizes the atom, which is then quickly neutralized by other electrons. In the neutralization process an x-ray with an energy characteristic of the parent atom is emitted. By collecting and analyzing the energy of these x-rays, the constituent elements of the specimen can be determined.

Optical microscopy is often overlooked as a tool for surface analysis. Modern optical microscopes are capable of capturing contrast detail from most surfaces. Lens design has allowed sufficient image brightness that detail can be readily resolved near the optical limit of resolution (0.25 mm). Use of a range of on- and off-axis incident light beams greatly extends the possibility of topographic contrast. power optical microscopes fitted with cameras facilitate direct connection with an image analysis system.

Scanning Electron Microscopy (SEM)

The Scanning Electron Microscope (SEM) is a microscope that uses electrons rather than light to form an image. There are many advantages to using the SEM instead of a light microscope. The SEM has a large depth of field, which allows a large amount of the sample to be in focus at one time. The SEM also produces ../images of high resolution, which means that closely spaced features can be examined at a high magnification. The combination of higher magnification, larger depth of focus, greater resolution, and ease of sample observation makes the SEM one of the most heavily used instruments in research areas today. By scanning an electron probe across a specimen, high resolution ../images of the morphology or topography of a specimen, with great depth of field, at very low or very high magnifications can be obtained. Compositional analysis of a material may also be obtained by monitoring secondary X-rays produced by the electron-specimen interaction. Thus detailed maps of elemental distribution can be produced from multi-phase complex materials. Characterization of fine particulate matter in terms of size, shape, and distribution as well as statistical analyses of these parameters, may be performed. The SEM is capable of carrying out both secondary and back-scattered electron (BSE) analysis, and is equipped with an energy dispersive X-Ray analysis system.

Ion chromatography (IC) is a form of liquid chromatography that uses ion-exchange resins to separate atomic or molecular ions based on their interaction with the resin. Its greatest utility is for analysis of anions for which there are no other rapid analytical methods. It is the separation and quantification of anions and cations using Liquid Chromatography (LC), extensively used in concrete materials engineering to quantify the pore solution chemistry. LC is an analytical technique based on the separation of the components of a mixture in solution by selective absorption. There are basically three modes of separation: liquid/liquid, liquid/solid, and molecular size. Once the components have been separated they are measured by a conductivity detector. Comparisons made against known reference materials. Concentrations of components can be determined by establishing a standard curve of known concentrations. Detection limits down to parts per billion (ppb) levels.

Infrared Spectroscopy (FTIR)

When a beam of electromagnetic radiation is passed through a substance, it can either be absorbed or transmitted, depending upon its frequency, and the structure of the molecule it encounters. When a molecule absorbs radiation it gains energy as it undergoes a quantum transition from one energy state to another. The frequency of the absorbed radiation is related to the energy of the transition by Planck's law. Thus, if a transition exists which is related to the frequency of the incident radiation by Planck's constant, then the radiation can be absorbed. Conversely, if the frequency does not satisfy the Planck expression, then the radiation will be transmitted. A plot of the frequency of the incident radiation vs. some measure of the percent radiation absorbed by the sample is the absorption spectrum of the compound. IR spectroscopy deals with transitions between vibrational energy levels in molecules, and is therefore also called vibrational spectroscopy. An IR spectrum is generally displayed as a plot of the energy of the infrared radiation (expressed either in microns or wave numbers) versus the percent of light transmitted by the compound.

Zeta Potential

Almost all particulate or macroscopic materials in contact with a liquid acquire an electronic charge on their surfaces. Zeta potential is an important and useful indicator of this charge, which can be used to predict and control the stability of colloidal suspensions or emulsions. The greater the zeta potential the more likely the suspension is to be stable because the charged particles repel one another and thus overcome the natural tendency to agglomerate. The measurement of zeta potential is often the key to understanding dispersion and aggregation processes in cement-admixture systems. Zeta potential depends on surface chemistry, not bulk chemistry.

Rapid Chloride Permeability (RCP)

Automatically integrates DC current flow to measure the chloride permeability of concrete samples. 4 samples can be tested simultaneously. The current range is 0-1 Amperes. The integration or test time is set to automatically terminate at the recommended six hours or may be manually terminated at any time. The test status as defined by the elapsed test time, current level and coulombs is printed out for all cores at 30-minute intervals. A manual print out can be obtained at any time.

Conduction calorimeter is used to measure the isothermal heats of hydration of small samples of ordinary Portland cements. The heat generated by a small sample undergoing a chemical reaction is allowed to flow only through a known thermal path, to a heat sink maintained at a constant temperature. The conductor forming the thermal path is a sensitive thermopile which produces an electrical output proportional to the heat flow through it. The calorimeter is immersed in a water bath, the temperature of which is controlled. An interface module is provided to act as a link between calorimeter and the microcomputer.

Used to measure elastic material characteristics. The non-destructive nature of the test and speed and ease of operations allow any number of repeated measurements to be made. It works on the impulse excitation technique. The procedure consists of exciting a test object by means of a light external mechanical impulse and the analysis of the transient natural vibration during the subsequent free relaxation. The excitation is given as to favor the desired vibration mode. A transducer is used to pick up the mechanical vibration. The instrument records all available periods and stores the result in the memory and the measurement corresponding to the purest waveform is displayed on the front panel.

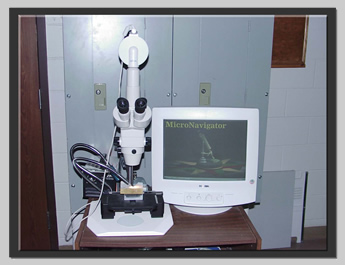

Hardened Concrete Air Void Analysis System

In hardened concrete, the type, amount, size, shape as well as the distribution of air voids are important properties that influence the compressive strength, durability and workability of concrete. For example, the presence of the proper quantity of entrained air voids can prevent the deterioration of concrete by freeze and thaw cycles and facilitate the placement of concrete. Determination of air void system in hardened concrete can be performed with several methods including linear transverse, modified point count, and image analysis. The most frequently used method in our lab is the modified point count specified in ASTM C457. With the point count equipment, air void, paste or aggregate appearing at each clicking stop can be recorded under the stereo microscope. Parameters such as air void content, void frequency, average chord length, specific surface area, and spacing factors can be calculated based on the ASTM C457.

Non-Contact Laser Displacement System

The Non-contact laser provides precise measurements of displacement, thickness, and vibration of objects, regardless of the surface color or texture. A laser beam is sent to the surface of the object and the reflected laser beam provides readings that are taken 40,000 times a second. Displacement signals are then picked up and sent to the digital display. This equipment can be used to determine the settlement behavior of different types of cement pastes, mortars and concretes.