This image shows the Purdue technology applied to a power generation and distribution grid.

Image provided

The COVID-19 pandemic has forced public health, supply chain, transportation, government, economic and many other entities to interact in real-time. One of the challenges in large systems interacting in this way is that even tiny errors in one system can cause devastating effects across the entire system chain.

Now, Purdue University innovators have come up with a possible solution: a set of patented algorithms that predict, identify, diagnose, and prevent abnormalities in large and complex systems.

“It has been proven again and again that large and complex systems can and will fail and cause catastrophic impact,” says Shimon Y. Nof, professor of industrial engineering and director of Purdue’s PRISM Center. “Our technology digests a large amount of data within and across systems and determines the sequence of resolving interconnected issues to minimize damage, prevent the maximum number of errors and conflicts from occurring, and achieve system objectives through interaction with decision makers and experts.”

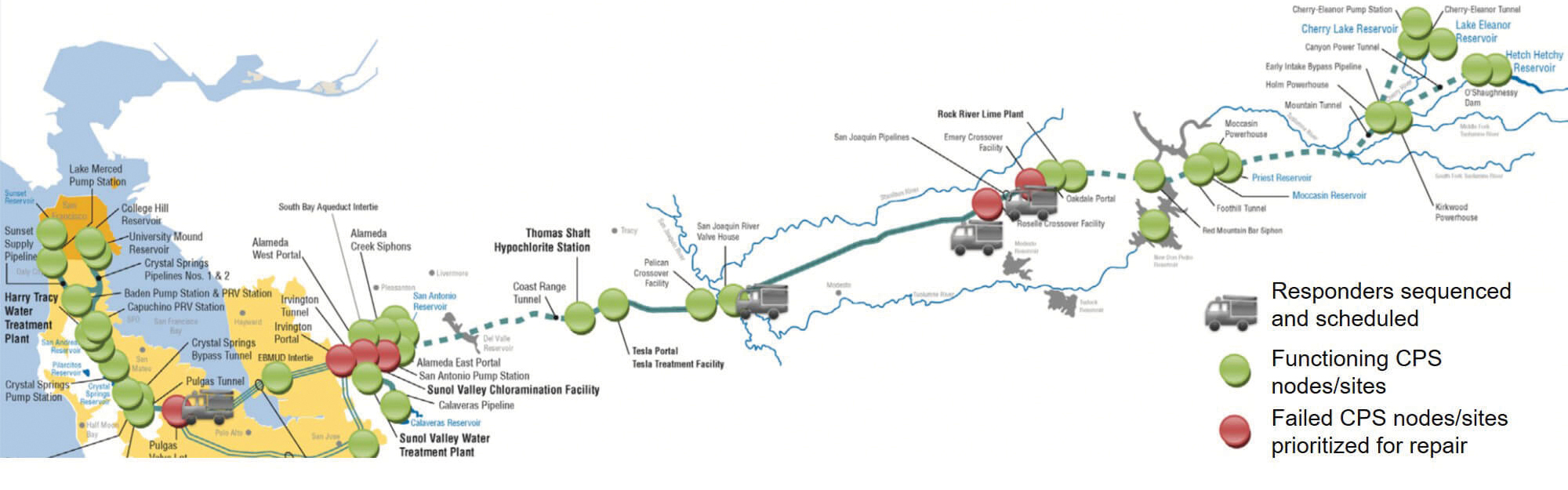

Nof says the system, invented at Purdue, determines how resources are allocated to repair failures. The system generates failure repair sequences based on information about failures — such as time, location, severity, causes and required repair resources — and available resources, and recommends failure repair sequences that meet system objectives.

“System sustainability requires effective and efficient repair of failures,” says Xin Chen, a former graduate student in Nof’s lab who helped create the technology. “This invention improves sustainability by optimally repairing failures with limited resources.”

This technology provides real-time failure diagnostics and failure repair sequences that minimize the impact and prevent cascading failures. Nof says the technology has applications for electrical power grids, logistics systems, and other systems that need to repair multiple failures.

It is part of the team’s work at the PRISM Center, focused on production, robotics and integration software for manufacturing and management. The researchers have created other systems, including a set of patented algorithms that predict, identify, diagnose and prevent abnormalities in large and complex systems.