Smart Factory

Source: Manufacturing Operations Management, Quality and Aerospace Talk

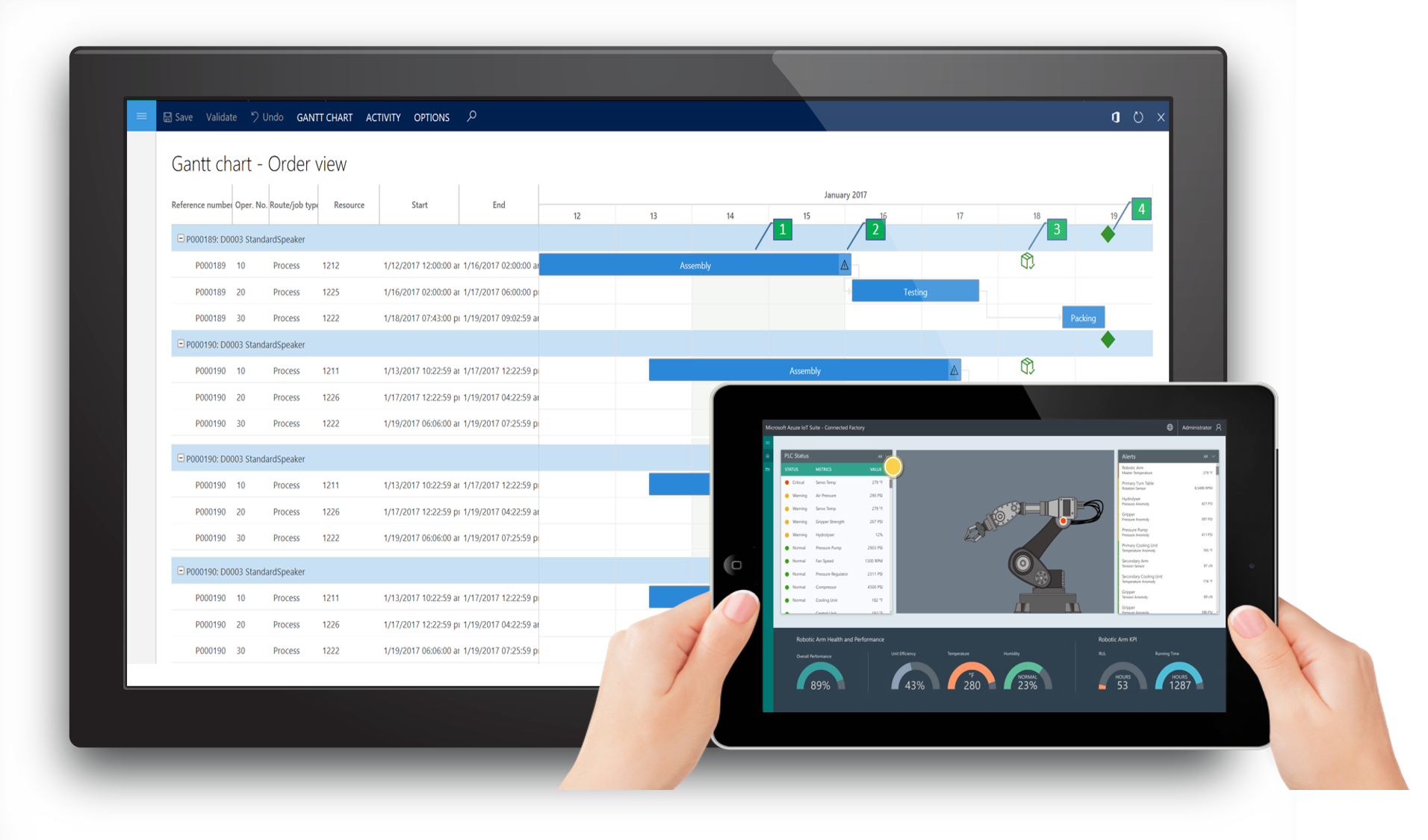

Scheduling and Control with Robots and Machine Learning Simulation of Autonomous Robots for Material Handling in Factory

The application of the word ‘smart’ has extended from devices into facilities like factories. Smart factories can be defined as a factory where machines interact with each other without human control based on collaborative Internet of things (IoT) and cyber-physical systems (CPS). To reduce the human control or intervention, the consideration of various data from devices is essential. This research cluster focuses on various problems such as scheduling with inductive learning and vehicle routing problems with autonomous mobile robots (AMRs).

Faculty Collaborators

- Dr. Seokcheon Lee (School of Industrial Engineering)

- Dr. Yuehwern Yih (School of Industrial Engineering)

- Dr. Hua Cai (School of Industrial Engineering)

- Dr. Hyonho Chun (Department of Mathematics and Statistics, Boston University)