SafespanTM:

Multi-Span Bridge Decking and Shielding

The Need

Contractors in bridge

rehabilitation have been experiencing risks and difficulties associated with their line of

work: safety and inspection issues, environmental concerns, business interruption,

emergency situations, and rising labor costs.

Traditional timber and conventional platform are labor intensive in erecting, and have

limited shielding abilities and limited access to the bottom flanges, steel beams, bridge

bearings, and concrete piers. More efficient, safer, and economical options of providing

access and work spaces in bridge rehabilitation are needed. |

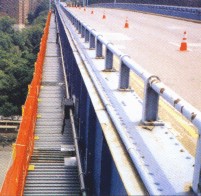

Safespan covered 114,000 sq. ft. in one phase

|

The Technology

Safespan Multi-Span Bridge Platform

System was developed by James Frangos and Lambros Apostolopoulos in 1995 to alleviate the

obstacles found in bridge rehabilitation. The system designs are flexible. It uses various

methods to connect the platform to the structure, depending on the bridge's configuration,

that allow contractors to adjust the platform's height for a desired working clearance.

This method enables contractors to solve the limited traffic under-clearance constraints

unique to their project. Safespan's patented

cable-suspended platform provides a stable working surface. The platform is supported on

cables fastened in equal intervals to the bridge's structural members. Then, steel decking

specially configured for the project's scope and weight requirements is attached to the

cables, using Safespan's custom-fabricated fasteners.

Safespan's decking provides secure shielding, supporting

loads up to 200 psf (976.4kg/m2). It completely shields the area under the

project from demolition debris and other hazards.

Side tarps create a full enclosure. This arrangement not only

contains dust and debris to meet environmental regulations, but also protects crews and

equipment from inclement weather, allowing work to continue in otherwise adverse

conditions. It enables maximum air flow for ventilation, heating and cooling.

Safespan essentially brings bridge projects to the ground,

allowing numerous spans to be accessed simultaneously. This feature permits multiple trade

crews to work concurrently, resulting in significant labor and cost savings. Safespan

employs reusable components, custom designed by Safespan's in-house structural

engineering staff to meet individual project requirements. Platform installation,

redeployment and removal proceed quickly with minimal traffic

disruption. |

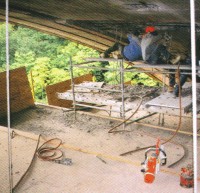

Safespan's addressed the outside fascia

Workers appear to be working on the ground

Safespan covered five spans at one hundred feet in

the air |

The Benefits

Accelerates contracting crews' performance with easy

installation and removal, providing simultaneous access to multiple work areas.

Stretches contractors' work season by dramatically increasing

productivity, thereby reducing time and labor costs.

Reduces contractor liability by shielding pedestrians and

vehicles from hazardous demolition debris.

Gets contractor's project approach approved by meeting or

exceeding Occupational Safety and Health Administration (OSHA) and American Association of

State Highway and Transportation Officials (AASHTO) requirements and facilitating site

inspections.

Mitigates environmental issues by retaining dust and debris

for easy clean-up and disposal.

|

Status

Safespan Multi-Span Platform System is a

patented system with multiple improvements patents pending. It has been used in several

painting and rehabilitation projects in U.S., such as:

- Painting project of Robert Moses Bridge across Fire Island

Inlet east of New York City.

- Concrete removal and shotcrete rehabilitation project of

Veterans' Memorial Bridge in Rochester, New York.

- Blasting and painting project of eight-span bridge in the

state of Connecticut.

- Roadway rebuilding project on the upper deck of the Henry

Hudson Bridge, New York City.

- Rehabilitation project of the Veterans Homes Memorial Bridge

in Minnesota.

|

Points of ContactDavid Malcolm, Safespan Platform Systems, Inc., 252

Fillmore Avenue, Tonawanda, NY 14150-2408, Phone: 1-800-368-4010 or (716)

694-1100, Fax: (716) 694-1188

References

- "Bridge Work Platform Saves Labor,

Money", Transportation Today, Engineering News Record, June 28, 99, p. T-93.

- John Gartner, "New Platform System Used

to Rehabilitate Bridges", Roads & Bridges, June 1997

- John Gartner, "Unique Platform Improves

Safety, Speeds Concrete Arch", Bridge Builder, June-July 1998.

- Safespan Platform Systems, Inc., http://www.safespan.com/

Disclaimer Statement

Neither the Construction

Safety Alliance nor Purdue University in any way endorses this

technology or represents

that the information presented can be relied upon without further investigation. |

|